당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

Model | LFCL-20FN |

Max. speed | 200 bpm |

Bottle outside diameter | φ35~φ100mm |

Bottle height | 45~200 mm |

Cap outside diameter | φ20~φ80mm |

Compress air | 4-7 bar |

Power supply | AC 220V, 50~60 Hz |

Air consumption | 200 L/min |

Measurement ( L×W×H ) | Approx. 2430 mm×900 mm×2600 mm |

Weight | 750kg |

FEATURES:

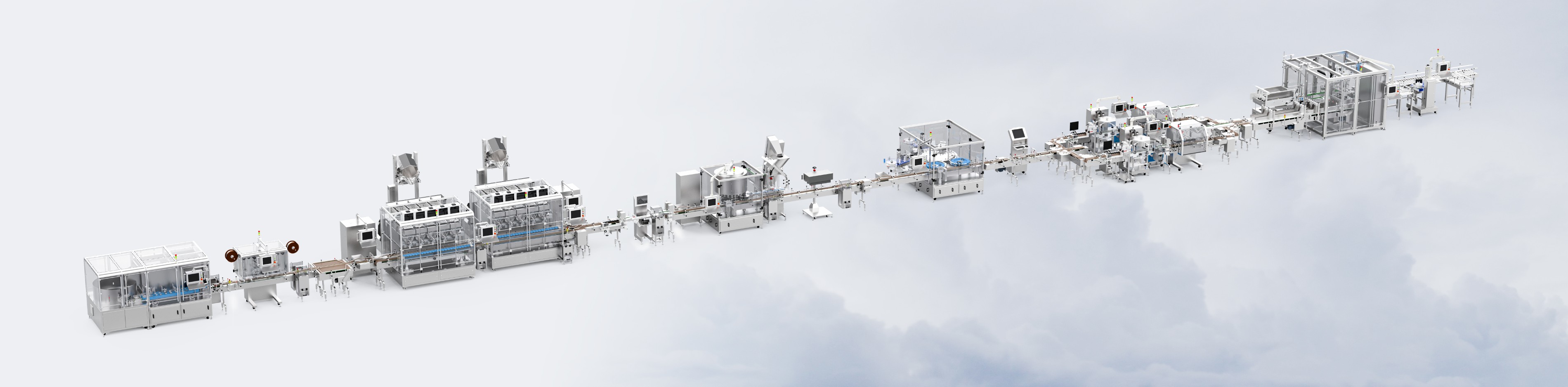

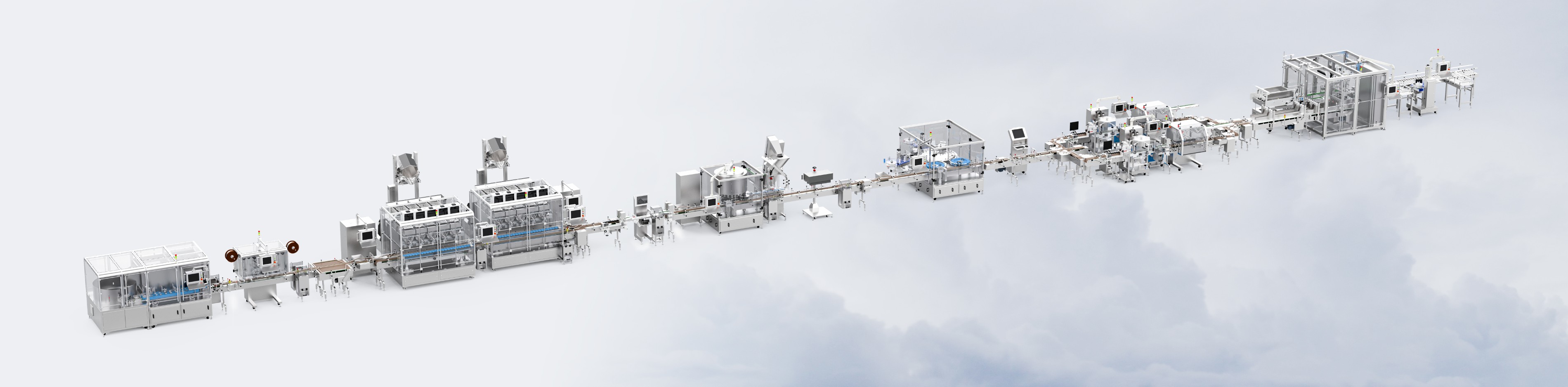

Inline Screw-on Capper LFCL-20FN is perfect for pharmaceutical, healthcare and food industries products. It can use a specialized device to screw the messy caps and bottles sent from the unscrambler to the next step at a certain speed.

Applicable products are cylindrical, elliptical cylindrical and rectangular plastic bottles with height between 45~200mm and outer diameter between φ35~φ100mm. Bottles that are too large, too small and not impact resistant (such as glass bottles) are not suitable for this machine.

It can be used with our automatic unscrambler, automatic counter and other filling counting devices, which are usually connected by conveyor.

WORKING PROCESS:

Manual or automatic product A into the storage B, from B to the cover, the lid of the cover through the falling cover slide d hanging from the front equipment sent to the mouth of the bottle G;The lid is moved forward by the CAP mechanism h after initial straightening, and the swivel cover is completed under the joint action of the swivel cover mechanism J.The bottle k that spins the lid is transported by the conveyor belt to the next process.Among them, hoist, bottle body I, the speed of the swivel cover mechanism J according to the production requirements, the condition of the material adjustment;The channel size of the drop slide d, the clamping mechanism I and the swivel cover mechanism J is adjusted according to the condition of the material, and the operation method refers to the corresponding part in the "Composition and introduction of the equipment" (Y2 is the magnetic moment clutch;Y11,y12 is a torque sensor).