당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

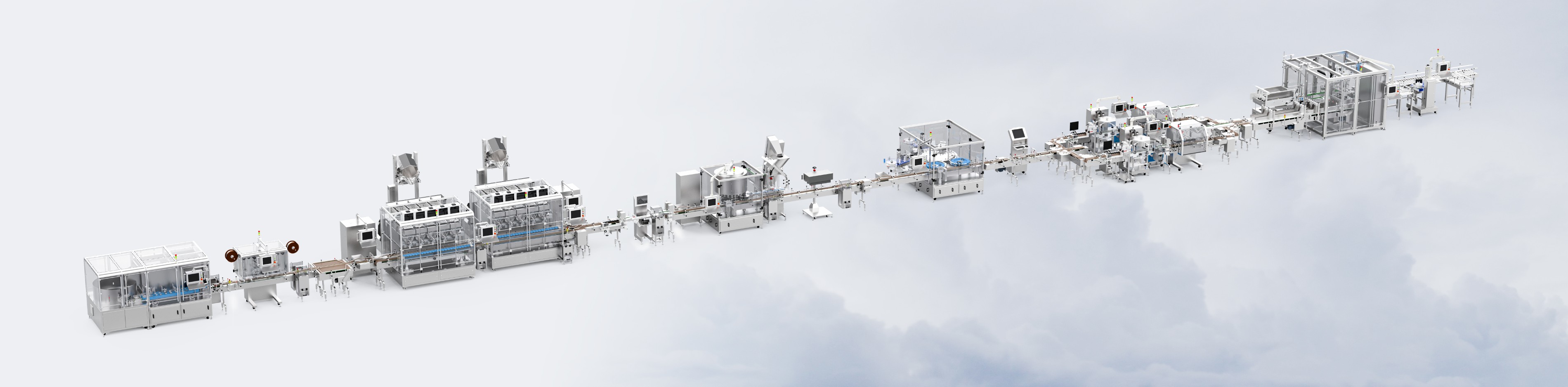

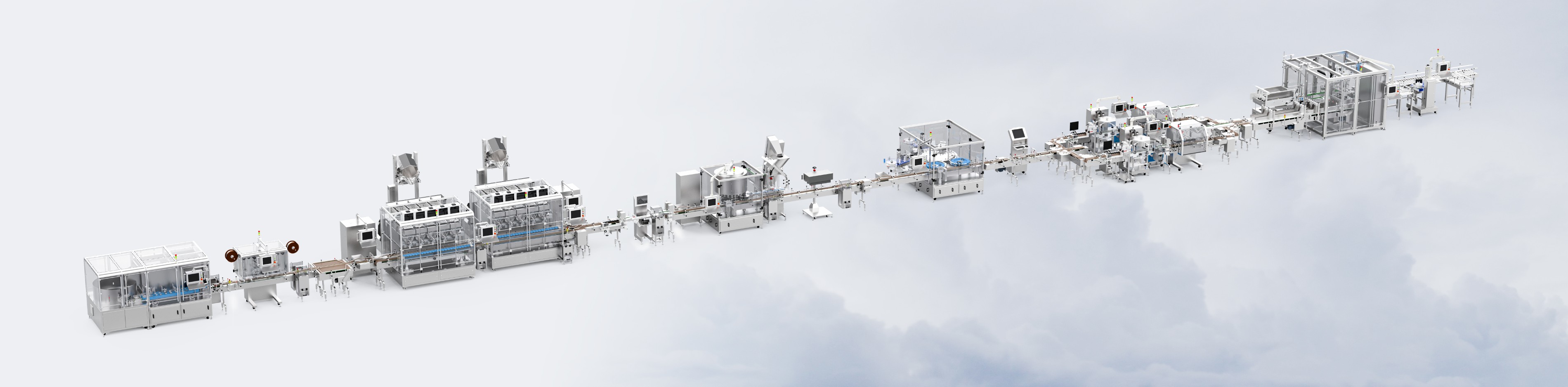

Model | LFCL-15/15M |

Max.speed | 150/200 BPM |

Bottle diameter | Φ35~φ80 mm |

Bottle Height | 45~200 mm |

Cap diameter | Φ20~φ80 mm |

Air pressure | 0.4-0.7MPa |

Air consumption | 30L/min |

Power supply | AC220V 50/60Hz 2.2kW |

Measurement ( L×W×H ) | Approx.1125×1135×2140 mm |

Weight | 650kg |

FUNCTION

The capper LFCL-15/15M is a reliable, high performance machine, designed in conformance with current and proposed GMPs. Having a small footprint, they are effective in maintaining the integrity of a clean room environment. Few change parts needed for different cap sizes (only the cap slide rail). The machine is designed for maximum efficiency and versatility. It utilizes the latest technology to automatically place and precisely torque a wide spectrum of cap types onto virtually any bottles type.

WORKING PROCESS

Due to the heat applied to the bottle cap to seal the aluminum foil, there is a chance of the cap losing its initial torque. The Retorquer is used to validate the torque on the cap and readjust the torque as needed.