당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

Model | LFBI-15 |

Max.speed | 150 cartons/min |

Carton specification(L x W x H) | 80~140 mm *35~120 mm *18~60 mm |

Bottle specification (D X H) | 75~135 mm *30~50 mm *14~50mm |

Booklet specification(L x W) | 70~300 mm *90~200 mm |

Booklet weight | 45-70g/m2 |

Power supply | 5Kw |

Power absorption | AC220V 50/60Hz |

Compressed air | 0.4~0.8MPa |

Air consumption | 100L/min |

Dimension(L x W x H) | Approx.3000mm(L)×1500mm(W)×1920 mm(H) |

Weight | Approx.2500Kg |

FUNCTION

It can put the bottle, blister p board, material holder and other materials into the carton and then sealed box.If you use it with our folding machine, you can load the manual into the paper tray.

This machine is suitable for food, pharmaceutical, cosmetics and other industries, and can realize the packing of bottles, blister board and related materials.

working principle

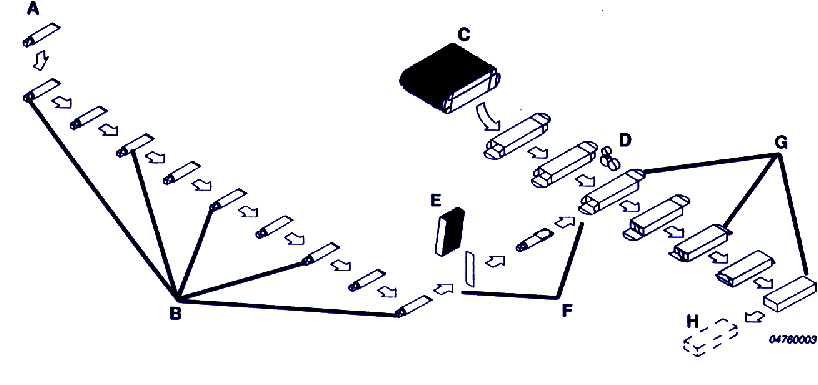

Manually or automatically place product A on the feed conveyor B. If the electric eye on the feed conveyor detects that a product has appeared, it sends a signal to suck the product from the material level C onto the U-shaped conveyor belt.

After the carton is sucked up from the silo, it is spread into a square shape and placed at the D position for the box to be coded. Then, the carton is sent to the cartoning station. At the same time, the manual comes from the E to the instruction inserting device F. When the product comes to the end of the conveyor belt, the instructions are pushed into the formed carton by the product under the action of the push rod.

The carton loaded with the product and the instruction manual enters the tooth-like carton conveying device, and the G-folding tongue device completes a series of folding tongue movements until the final sealing box.

The cartoner outlet is equipped with a carton reject device H, which is used to detect and reject the unqualified carton.