당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

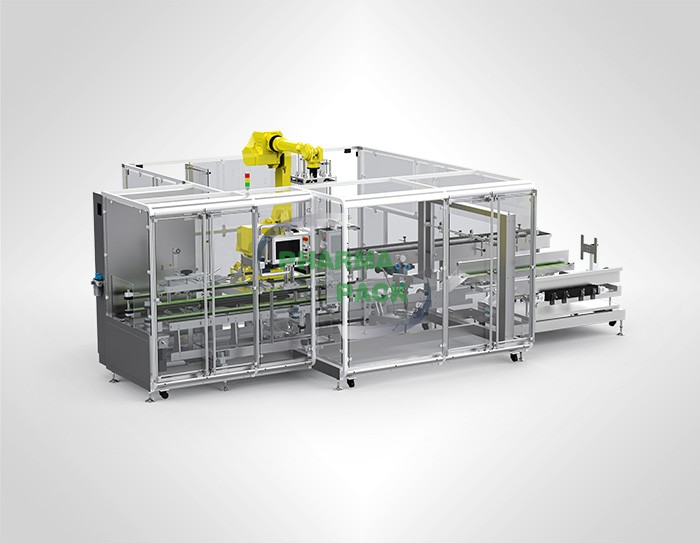

Model | ALFC-04S |

Max. Speed | 5 cases/min(Depends on the carton size and the packed product) |

Case size / L* W* H | L400-700mm *W200-400 mm *H170-200 mm |

Power consumption | 8kw |

Power supply | AC380V-400V 50/60Hz |

Air pressure | 0.5-0.8MPa |

Air consumption | 100L/min |

Machine size/ L*W*H | 6200mm(L)×2600mm(W)×2700 mm(H) |

Machine weight | 1700Kg |

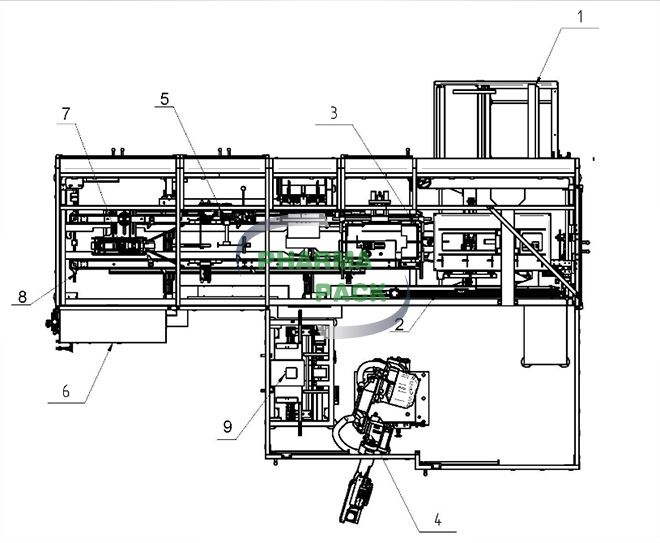

WORK FLOW

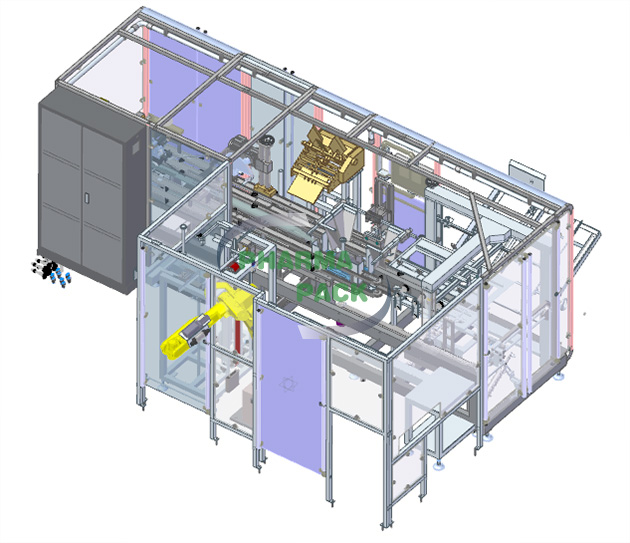

Boxes are delivered inside the machine via the conveyor belt. The robot arm moves to the tail end of the conveyor belt, the robot clamps clip the product, and the arm moves to the carton to put the product into the carton. The robot arm moves to the position of the compartment, the robot clamps clip the compartment, the arm moves to the carton into the carton, manually put the cardboard in a fixed direction, and press with the press of the box; the unpacking parts are driven by the cylinder, the vacuum suction and pull out the cardboard; after forming, the front and rear folding parts, folding all folding at the bottom of the box by the servo control. After the carton is formed in place, the robot completes the packing action; after the packing, the carton is transported backward, and the sealing mechanism folds the front and right box cover in place, and then the tape mechanism finally completes the tape action and closes the box.

FEATURES

The frame is stainless steel, strong and good outlook. The frame of aluminum profile and organic glass overall design, the overall beautiful.

The whole machine adopts imported electrical components, stable and durable, high safety performance; humanized human-machine interface, easy to operate.