당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

Model | LFM-08 |

Max. speed | 6000 pieces/min |

Filling volume | 1-200 pieces |

Application scope | Pill, tablet, soft and hard capsules, etc. |

Tablet size | Φ3-Φ20mm Pill, tablet, soft and hard capsules, etc. |

Bottle diameter | Φ20-Φ80mm |

Bottle height | 40-200mm |

Power supply | AC220-240V-50/60Hz |

Compressed air & Air consumption | 4.9-7bar、200L/min |

Power consumption | 3KW |

Machine dimension / L*W*H | 1950mm(L)×1500mm(W)×1850mm(H) |

Machine weight | 900Kg |

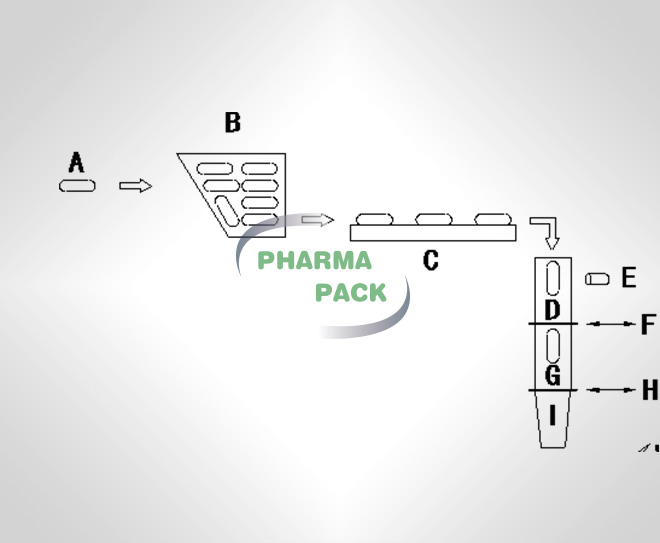

WORKING PRINCIPLE

Products are loaded into the hoppers manually or automatically (option), and then fed onto the three-grade vibratory plates. By adjusting the vibration frequency of the vibratory plates, the products can be allowed to move through channels of the plates continuously and in single file. At the end of channels the products fall into detection tunnels, where using the principle of the photoelectric effect to input the working signal generated by the infrared dynamic scanning sensor when the drug particle falls down into the high-speed microprocessor (MCU), and realizes the counting function through the cooperation of the electronic and the mechanical. The product of each 8 channels fall into a filling nozzle, and at the same time, the set number of products are all filled into the bottles respectively with the help of the four vibration filing nozzle.

Below image with 4 vibrating filling nozzles is just for your reference.

FEATURES

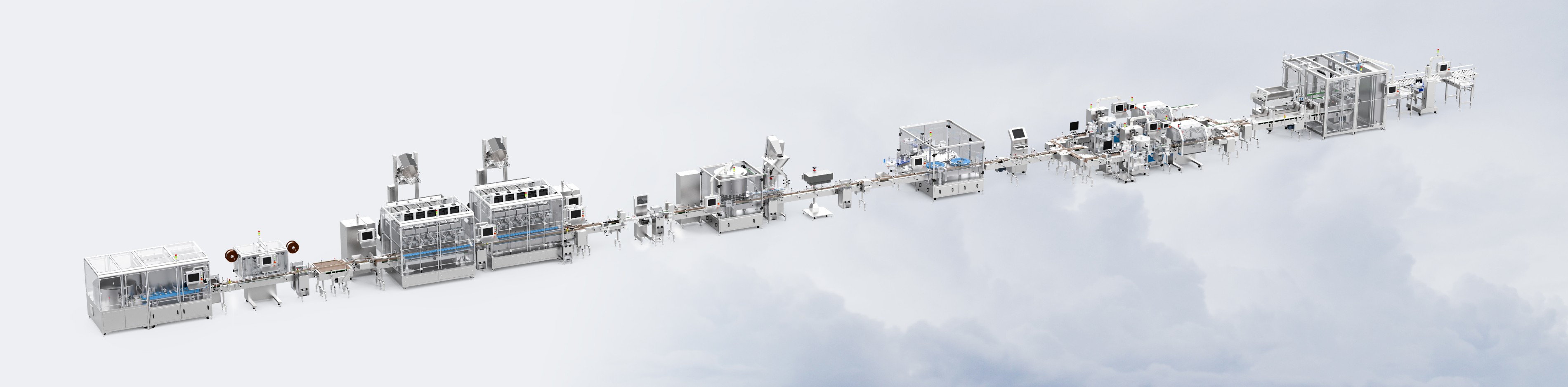

1.LFM-08 consists of 5 Modules, Continuous Infeed Screw, Follow-up Device Servo Controlled System, Rejection with Star Wheel Servo system and so on.

2.The servo system ensures that all motion units work in complete synchronization, so as to ensure that 5 assembly bottles work continuously at the same time, with faster speed, higher precision and more stable work.

3.It can realize uninterrupted and continuous action of filling&counting, with high equipment efficiency, and rejection system with the one-to-one correspondence ,with precise and continuous action.

4.Servo motor controlled general gate, continuous filling & counting system with screw, minimize noise and comply with cGMP standard.

5.Perfect modular structure, based on customer speed or configuration requirements, it can be any combination, and each group of modules can be independently controlled, do not affect each other.

6.Optional with a higher degree of automation of remote control system or SCADA system.

7.The vibrator is driven by direct current to transport the tablets/capsules smoothly and evenly.

8.Dust removal efficiency can be improved by controlling the size and direction of air inlet.

9.PHARMAPACK and FESTO cooperate to develop special dustproof cylinder to effectively filter dust and extend the service life of cylinder.

10.PHARMAPACK patented Counter with double gates structure, effectively improve the bottling speed.

11.Each channel has 4 groups of counting sensors to transmit and 8 groups to receive. Patch technology is adopted to install the receiving sensor. Special counting software and light source technology ensure the accuracy of counting of the tablets/capsules.

12.Connect the control system of all devices in the whole line through Ethernet to complete remote monitoring, management and maintenance.