당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

Model | ALFM-32C |

Max. output | 24,000 pcs/min(Dependant on product and container size) |

Fill qty. per bottle | 1~200 |

Product size | Thinkness:3~10mm Dia:3~20 mm Length:3~21mm(Suitable for tablets, capsules, pills, caplets, soft gels etc.) |

Container size | Dia.:20~100 mm Height:40~240mm |

Power supply | AC220V 50/60HZ |

Wattage | 20 KW |

Air pressure | 200L/min, clean air |

Air consumption | The above speed depends on packing material |

Measurement(L*W *H) | Approx.4000(L)*2100(W)*2000(H)mm |

Weight | Approx. 4200kg |

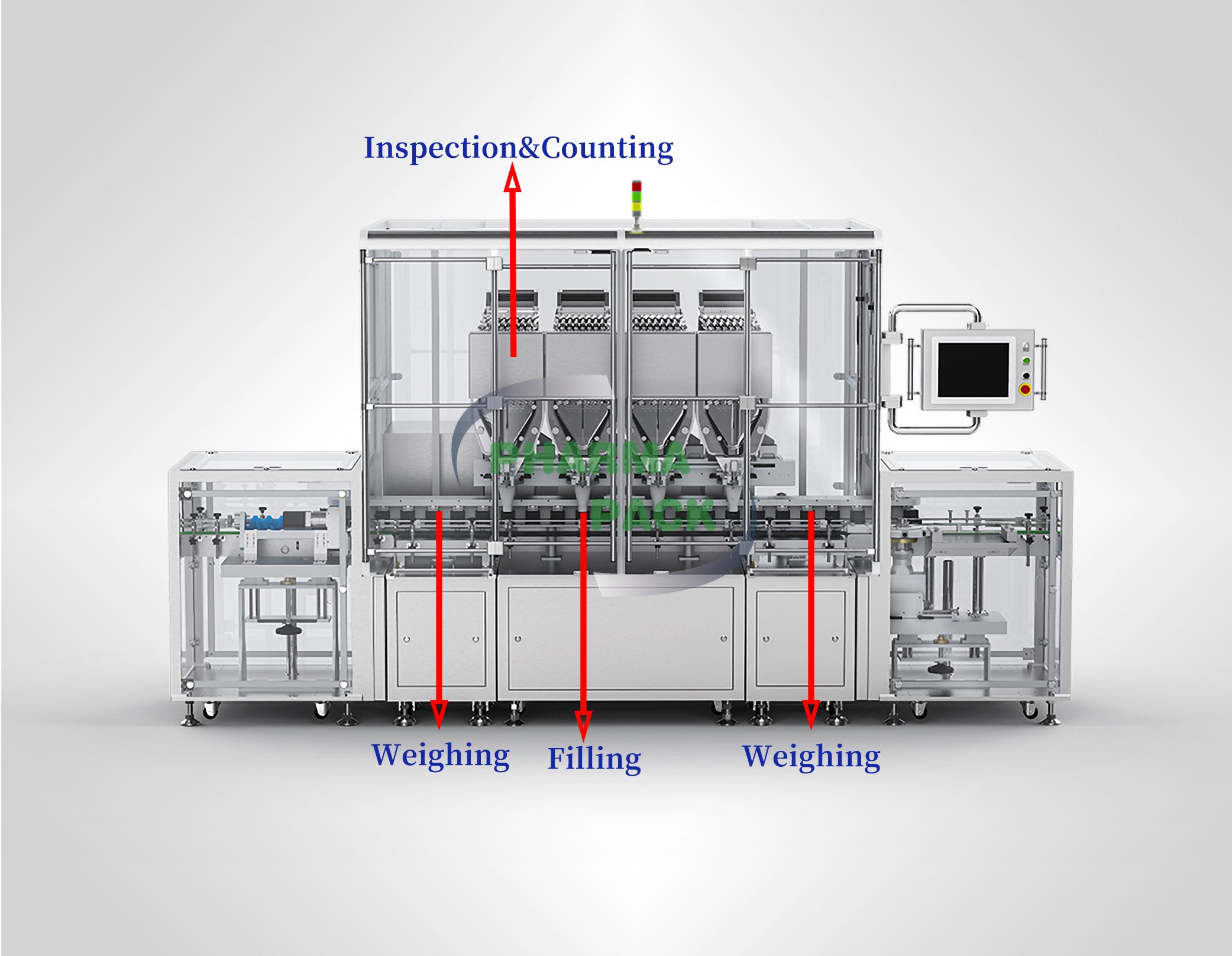

Pharmapack launched the 360 Counting & Sorting machine for Tablets, Capsules and Soft gels into the bottles, the pharmaceutical and nutraceutical industry. It integrates counting, inspection, filling and weighing functions into one machine, to ensure the counting accuracy and save space.

WORKING PRINCIPLE:

1. Products are loaded into the hoppers manually or automatically (option), and then fed onto the three-grade vibratory plates. By adjusting the vibration frequency of the vibratory plates, the products can be allowed to move through channels of the plates continuously and in single file. At the end of channels, the products fall into detection tunnels, where using the principle of the photoelectric effect to input the working signal generated by the infrared dynamic scanning sensor when the drug particle falls down into the high-speed microprocessor (MCU), and realizes the counting function through the cooperation of the electronic and the mechanical. The product of each 8 channels fall into a filling nozzle, and at the same time, the set number of products are all filled into the bottles respectively with the help of the four vibration filing nozzle

2. Static weighing: Before filling, the empty bottle (or bottle with desiccant) is transferred to weighing system by the screw. After weighing, the bottle weight data will be obtained and stored. Then the bottle into filling station and complete product filling. Once again, the bottles will be weighed after filling. The machine itself will compare the weight before and after filling to ensure the accuracy.

3. Those bottles with different weight (caused by different count and different weight products) will be rejected by the rejection star wheel;

HIGHLIGHTS:

·Modular design, full servo-control

·Multifunction machine for inspection, counting, bottle filling and weighing

·Exceptional 100% visual inspection of tablets, capsules & softgels.