당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

Model | PP-12LC |

Max.speed | 12000 pcs/min |

Dosage/btl | 1-200pcs |

Application | pills、tablets、soft or hard capsule 、and other solid medicine |

Tablet size | Φ3-Φ13mm |

Bottle size | Φ20-Φ80mm |

Bottle height | 40-240mm |

Power supply | AC220-240V 50/60Hz |

Air consumption | 4-7bar、100L/min |

Power absorption | Approx.10.0KW |

Dimension (L×W×H) | Approx.2100mm×2250mm×2250mm |

Weight | Approx.3000Kg |

FUNCTION:

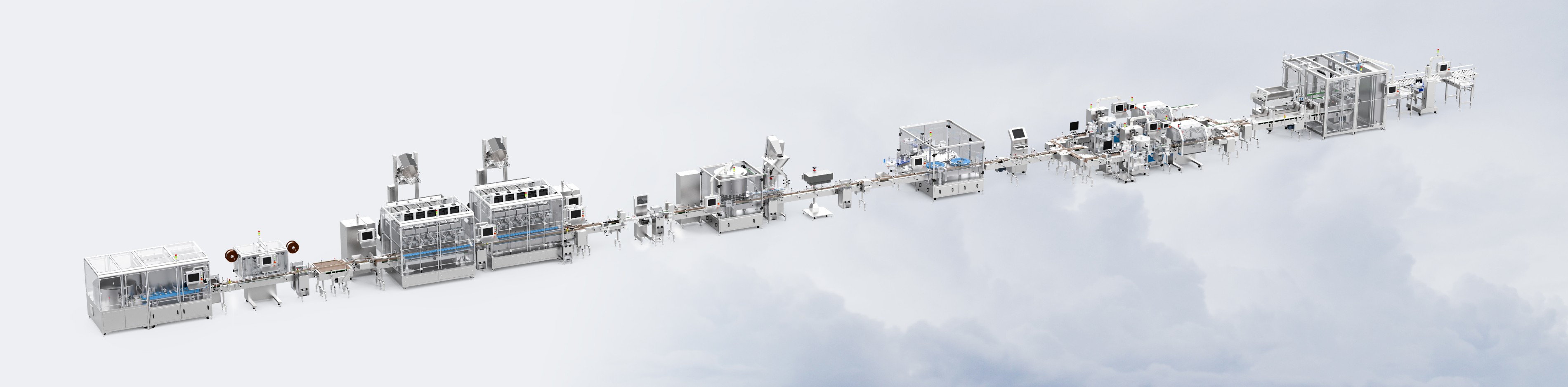

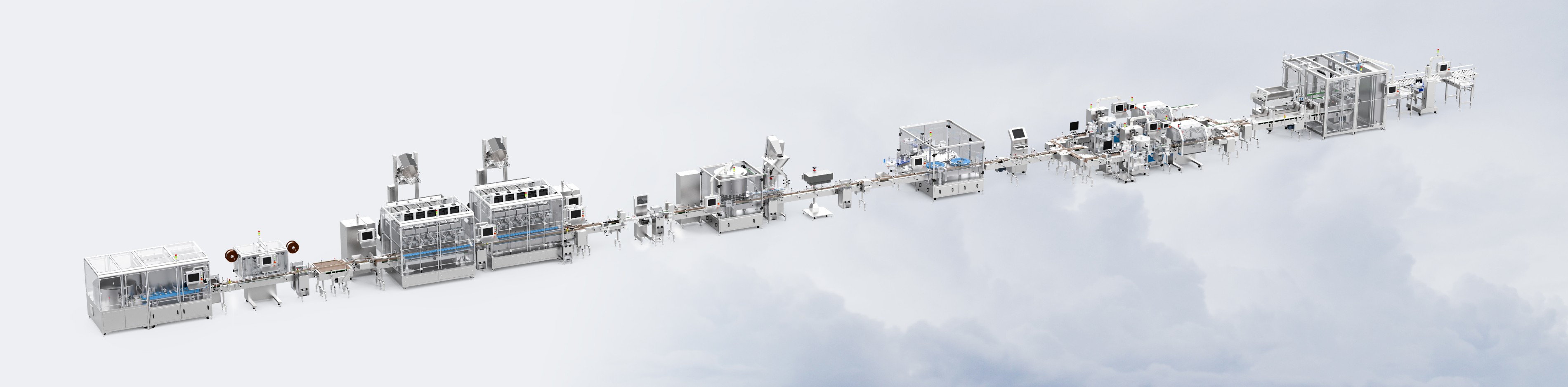

PP-12LC is composed of 4 groups of single modules, continuous screw servo feeding system, servo system, rejecting star wheel servo system and so On.Through the servo system to ensure the complete synchronization of the motion unit, so as to ensure continuous 4 assembly bottle work, faster, more accurate, more stable work.

PP-12LC automatic modular counting machine is manufactured using advanced Technology.The machine is made of high quality stainless steel, The appearance is exquisite, the mechanism is simple, the shape is beautiful, the maintenance is convenient.It can be widely used in the pharmaceutical industry of solid formulations of the counting bottles, such as pills, sugar-coated tablets, tablets, soft /hard capsules and other shaped tablets.

Working principle:

Manual or automatic pellet A is loaded into the silo B, through the appropriate adjustment of the vibration frequency of the three-stage vibration feeder C, so that the particles in the silo along the Three-stage vibration supply system Vibrating Groove plate 6 track continuously down to the blanking port, into 6 optical detection channel D, through optical detection of electric eye E and related control system count, and collected on the channel material gate H, to achieve the set bottle volume, close the material doorf, at the same time open the material door H, so that the bottom hopper g within the drug particles through the nozzle I fell into the vial under it, and then close the material door H, open the material door f, through the bottle screw to move the bottle, so that the bottle down a station, so the cycle, Complete the dosing process of the pellet count.