당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

Model | LF-08 |

Max. output | 8,000 pcs/min |

Fill qty. | 1~1000 |

Product size | Thinkness:3~10mm Dia:3~13mm |

Container size | Dia.:20~100mm Height:40~240mm |

Power supply | AC220V 50/60HZ |

Wattage | 3.5KW |

Air pressure | 0.5~0.7Mpa |

Air consumption | 200L/min, clean air |

Measurement(L×W ×H) | Approx. 1980mm×1580mm×1740mm |

Weight | Approx. 800kg |

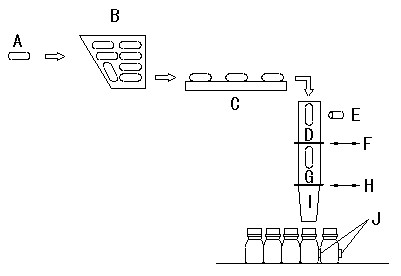

WORKING PRINCIPLE

Products (A) are loaded into the 2 hoppers (B) manually or automatically (option), and then fed onto the 2 sets of three-grade vibratory plates (C). By adjusting the vibration frequency of the vibratory plates, the products can be allowed to move through 16 channels of the plates continuously and in single file. At the end of channels the products fall into 16 detection tunnels (D), where the products are counted with the help of combination of sensors (E) and control system. The counted products are collected on the nozzle gate (H). When the preset count is reached the tunnel gate (F) closes and in the meantime the nozzle gate (H) opens to allow the counted products in the funnel (G) to drop into the bottle via the nozzle (I). After the bottle is filled the nozzle gate (H) closes and the tunnel gate (F) opens. Meanwhile, the bottle positioning cylinders work to release the filled bottle and get the next empty bottle positioned under the nozzle.

PERFORMANCE

The counter LF-08 is a reliable, high performance machine, designed in conformance with current and proposed GMPs. Having a small footprint, they are effective in maintaining the integrity of a clean room environment. Few change parts are needed for different container sizes (only the nozzle). All product contact parts are made of type 316 stainless steel. And all contact parts can be easily disassembled for cleaning.