당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

It's an automatic counter. Small footprints allow it to integrate into any packaging line. It’s an automatic tablet counter that counts and bottles at the same time to improve production efficiency.

Category: Smart Bottle Packaging Line, Counter

Model | LFM-32 |

Max.Speed | 24000pcs/min |

Dosage/btl | 1~1,000pcs |

Tablet size | Φ3-Φ20mm; Applicable to tablets, capsule, caplets, soft gels, transparent soft capsules etc. |

Bottle size | Dia: 20-80mm, Height: 40-240mm |

Power supply | AC220V, 50/60Hz |

Power absorption | Approx. 10.0kw |

Air pressure | 4.9-7bar |

Air consumption | Approx.300L/min |

Dimension (L×W×H) | Approx.1900mm×2150mm×2150mm |

Weight | Approx.2500kg |

System Description

High-speed automatic counter with 400 Bottles per minute

Filling of bottles while bottles are in motion. Bottle need not stop for filling

Each module head consist of eight channels

Option for In-Built Tablet Inspection System

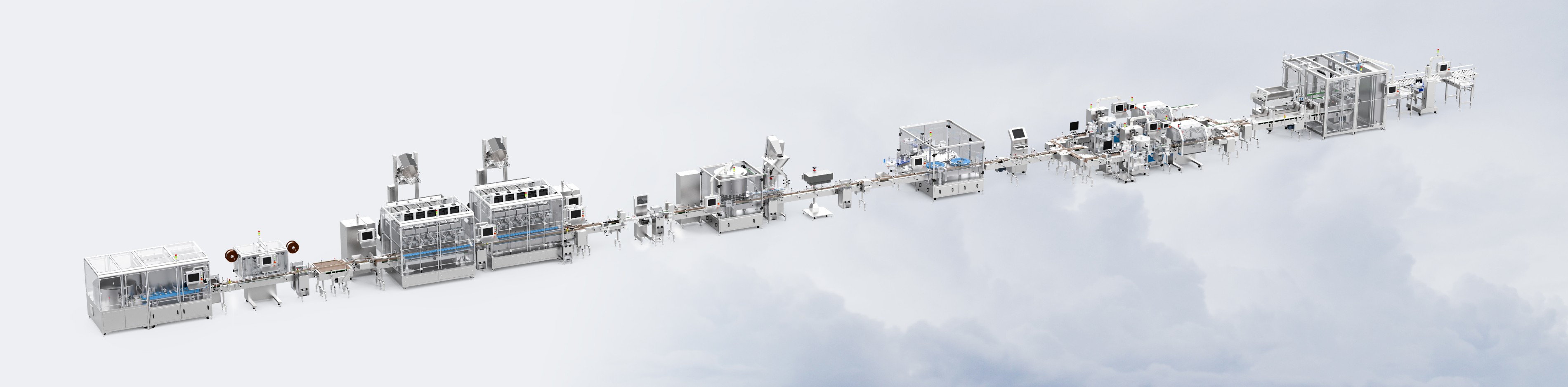

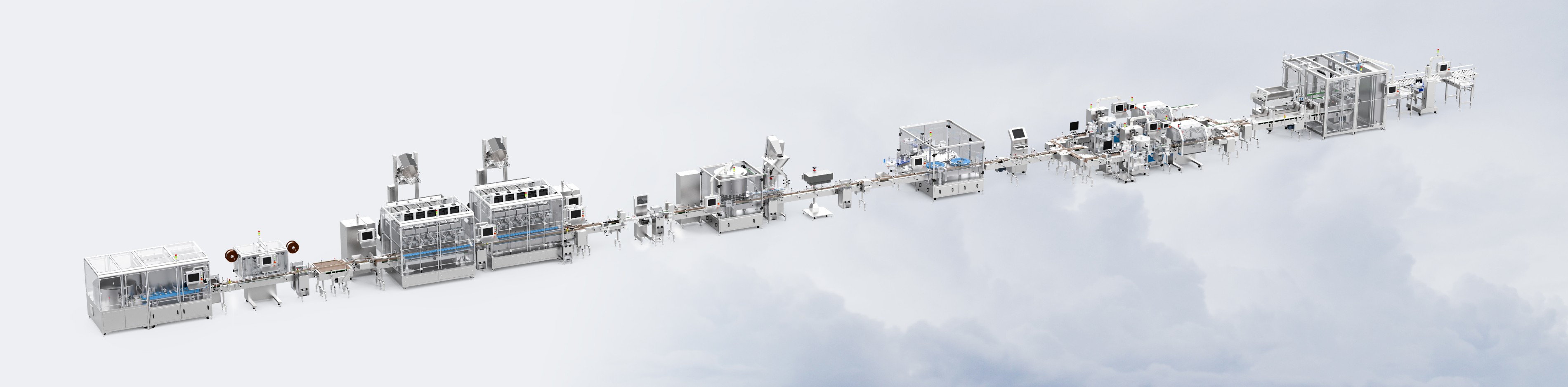

The automatic counter LFM-32 uses the Pharmapack PP- Modular Series Continuous Motion counting and the filling system consists of a flexible mainframe wherein one can select and incorporate a variable number of 4-6-8-10 modules heads with the efficiency of filling up to 400 bottles per minute. It can easily be integrated into a bottle packaging line with small footprints and few change parts. The changeover is toolless, simple, and quick. With No Hidden traps for tablets, the cleaning is clean quick, and simple.

Main Features

Fully modular design, total modules are designed as unique and have separated parts

Ease of operation with a minimal number of settings

Small footprints allow integration into any packaging line

Automatic counting and bottling at the same time to improve production efficiency

Three-grade vibratory plates with 8 channels to deliver and separate the products for the counting operation with no overlapped products;

Fault auto-diagnosis and real-time monitoring alarm display system, and can store 100 sets of product parameters

Accurate bottle rejection mechanism

Handling Tablet/Capsule size ranging in size from 1.5 mm to 21 mm in length

It accommodates a wide assortment of containers, including round, oval, square, and rectangular up to 160 mm height.

All automatic tablet countersuse

21 CFR part 11 software

Solution

We know that every business is different. That’s why we provide a variety of custom packaging equipment that meets the unique needs of our clients.

Industry Application

Model: LFM-32

Function: A patented machine for high-speed counting of pills and capsules.

Industry: Pharmaceutical, healthcare, food

How Pharmapack automatic tablet counter can help your production

Servo controlled system can lower production noise and lower running costs by requiring fewer spare parts. Conforms with GMP norms. User-friendly touch screen IPC.

Customized Services

Pharmapack provides turnkey packaging solutions tailored to its customers. Pharmapack offers individual solutions based on the data and needs provided by different customers.

lProfessional pre-sales and after-sales service center in Asia, Europe, and North America.

lSolutions for design aspects, commissioning, maintenance, or upgrades.

lDedicated 24-hour online customer service group

Cases

At present,Pharmapack electronic tablet countershave been exported to more than 30 countries and regions around the world. We have successfully provided line installations for many well-known companies.

International:

Such as Pfizer, GSK, Johnson & Johnson, Abbott, Sanofi, AstraZeneca, Baxter, Mars, Wrigley, Perfetti, L'Oreal, AVON.

Domestic:

TongRenTang, Salubris, Jilin AoDong, North China Pharmaceutical Company, Harbin Pharmaceutical Group Holding Co., Ltd.

Yunnan Baiyao Group Co., Ltd, Guangzhou Pharmaceuticals. The Yangtse River, Tasly Pharma, Infinitus, BY HEALTH, etc.

Why choose Pharmapack Machine

Experienced R&D Group PharmaPack congregates advanced technology in the world to supply the most advanced and guaranteed technical support for our customers. |

One-stop Service System Pharmapack can supply the most perfect "turn-key" packaging solutions for every customer. |

Industry-leading Technology New servo control with self-detection to replace the old cylinder, the flapper free of dust effect, more stable, longer life-span, lower maintenance cost. | Excellent Quality Control Tested by internationally certified companies, Pharmapack equipment has passed the evaluation of CE, UL Certify, CSA and complies with GAMP, FDA (CFR21), cGMP, and TGA standards. |