당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

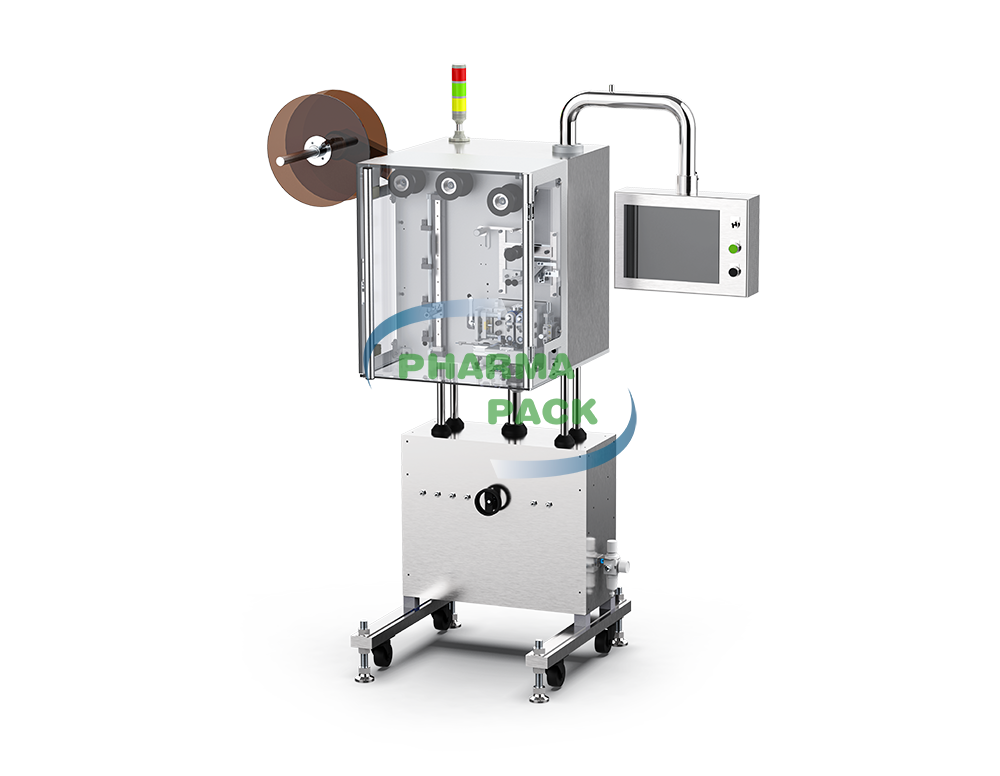

LFID-20 is a desiccant inserter. It’s designed specifically for the pharmaceutical, healthcare, and food industries.

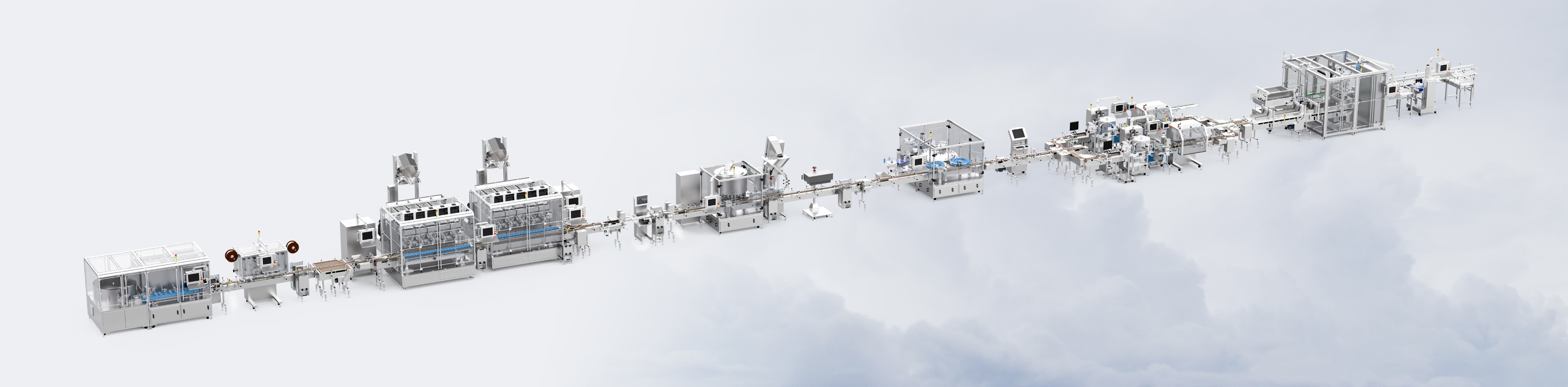

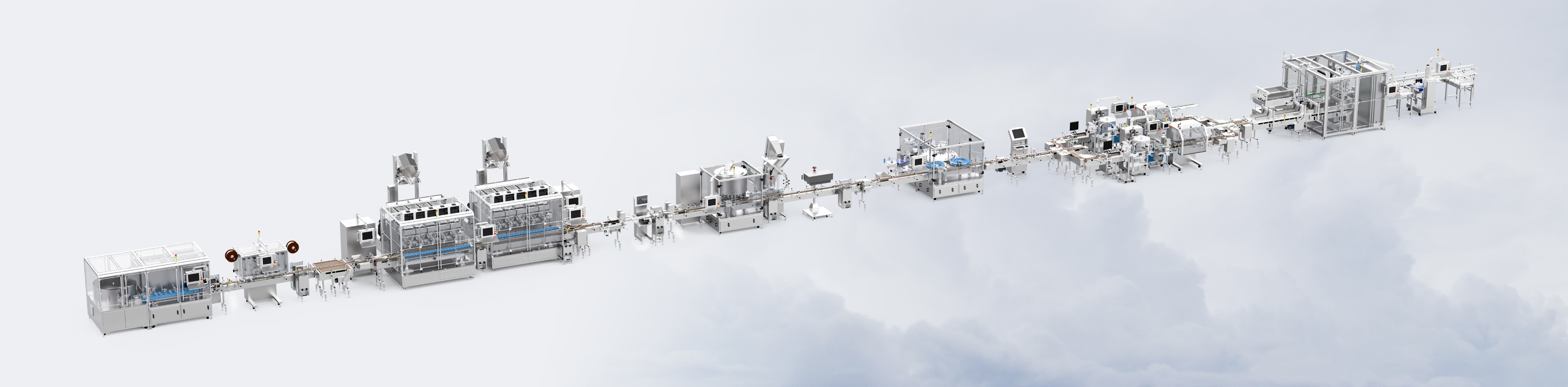

Category: Smart Bottle Packaging Line, Inserter

Model | LFID-20 |

Max. speed | 200 bottles/min |

Air pressure | 0.4-0.7Mpa |

Air consumption | 30/min |

Power supply | AC460V 50/60Hz 400W |

Dimension | 610mm(L)×1677mm(W)×450mm(H) |

weight | 160kg |

Features

Desiccant inserter machine LFID-20 is specialized equipment designed to cut the desiccant sachet automatically and insert it into bottles, cartons, and bags which are filled with tablets, pills, capsules, or another solid medicament. It is designed for the industry of pharmaceutical, health care, and foodstuff, and other similar fields. Its compact structure and fine design allow for easy maintenance and conform to GMP standards equipped with Servo-driven and PLC control system with a touch screen offering easy and reliable operation.

Application

The inserter machine can be used separately or combined with a fully automatic unscrambler, automatic electric tablet/capsule counter, screw capper, electric-magnetic induction sealer, and labeler, etc. Equipment including desiccant inserter made by our company to form an integrated packaging line for plastic containers also can be incorporated with another similar packaging line.

Working process

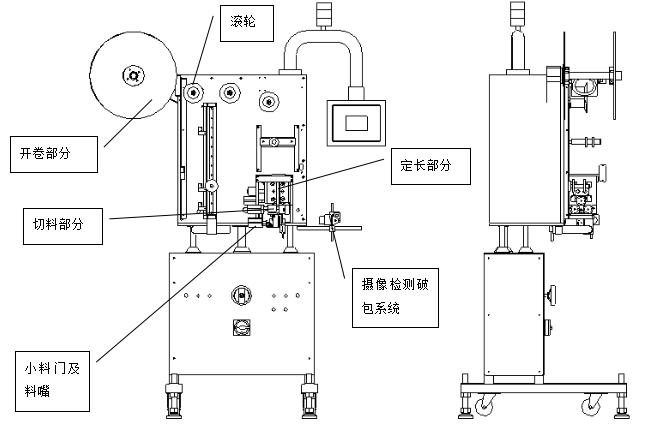

(1) The sachet desiccants are loaded onto an uncoiling roll. The desiccant roll rounds across each roller and goes to length transmit device, then to the desiccant cut device at last.

(2) When the sensor detects bottles on the conveyor, the length of the desiccant switch will be triggered and the desiccant will be cut by a cutting knife(general gate is closed).

(3) The non-broken desiccant will be dropped into bottles by opening the general gate. When the camera detects broken desiccant through the clear nozzle, the general gate will not be opened until the broken desiccant is cleared and the present bottle will be rejected.

(4) The pneumatic system shifts bottles automatically when bottle shift time delay is reached(camera detection system is optional).

During the whole working process of the desiccant inserter, the desiccant roll is tightly pressed by the length control unit. Cutting length and cutting position is respectively controlled by servo motor and detect sensor.

Solution

We know that every business is different. That’s why we provide a variety of custom packaging equipment that meets the unique needs of our clients.

Industry Application

Model: LFID-20

Function: LFID-20 is a desiccant inserter. It is specialized equipment designed to cut the desiccant sachet automatically and insert it into bottles

Industry: Pharmaceutical, healthcare, food

How Pharmapack Desiccant Inserter can help your production

Pharmapack desiccant inserter is ideal for keeping up to speed with your packaging demands. Our inserter machines are designed for long-lasting, consistent operation and are suitable for your specific bottle size range and speed. Parts of the machine are safe to operate, user-friendly, and are manufactured for your operation to run efficiently and smoothly.

Customized Services

Pharmapack provides turnkey packaging solutions tailored to its customers. Pharmapack offers individual solutions based on the data and needs provided by different customers.

lProfessional pre-sales and after-sales service center in Asia, Europe, and North America.

lSolutions for design aspects, commissioning, maintenance, or upgrades.

lDedicated 24-hour online customer service group

Cases

At present,Pharmapack electronic tablet counters have been exported to more than 30 countries and regions around the world. We have successfully provided line installations for many well-known companies.

International:

Such as Pfizer, GSK, Johnson & Johnson, Abbott, Sanofi, AstraZeneca, Baxter, Mars, Wrigley, Perfetti, L'Oreal, AVON.

Domestic:

TongRenTang, Salubris, Jilin AoDong, North China Pharmaceutical Company, Harbin Pharmaceutical Group Holding Co., Ltd.

Yunnan Baiyao Group Co., Ltd, Guangzhou Pharmaceuticals. The Yangtse River, Tasly Pharma, Infinitus, BY HEALTH, etc.

Why choose Pharmapack Machine

Experienced R&D Group PharmaPack congregates advanced technology in the world to supply the most advanced and guaranteed technical support for our customers. |

One-stop Service System Pharmapack can supply the most perfect "turn-key" packaging solutions for every customer. |

Industry-leading Technology New servo control with self-detection to replace the old cylinder, the flapper free of dust effect, more stable, longer life-span, lower maintenance cost. | Excellent Quality Control Tested by internationally certified companies, Pharmapack equipment has passed the evaluation of CE, UL Certify, CSA and complies with GAMP, FDA (CFR21), cGMP, and TGA standards. |