당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

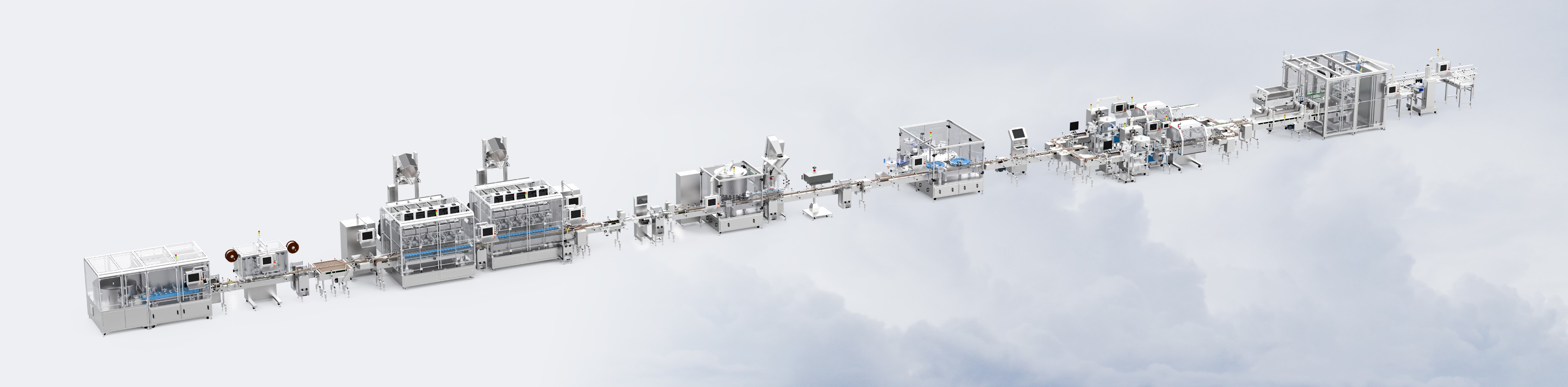

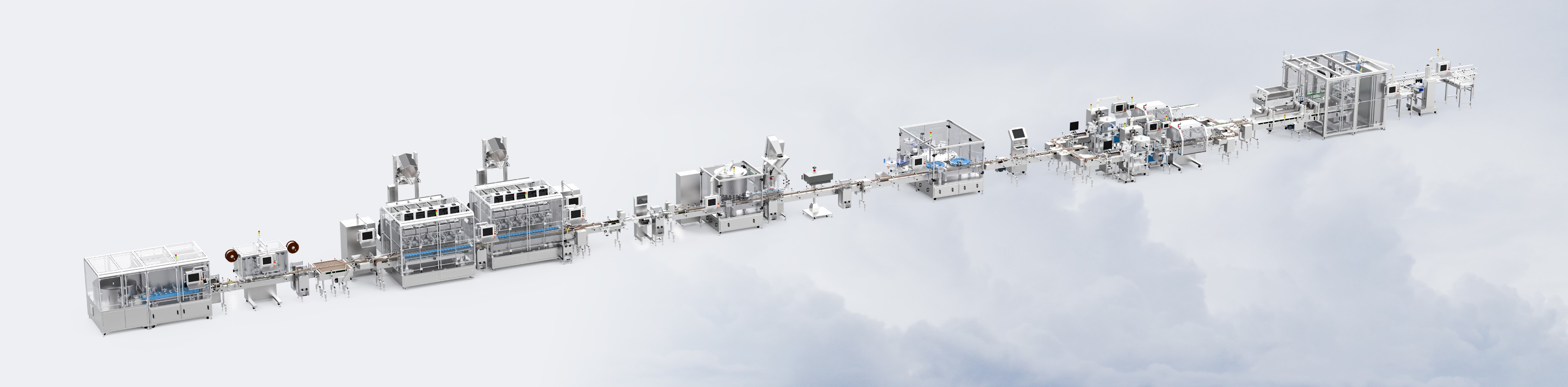

Model | LFLB-3220 |

Max. output | 200 bpm |

Max. label dispensing speed | 60 m/min |

Bottle shape | Flat bottle |

Max. label width | 110mm (180mm in option) |

Labeling accuracy | ±0.5mm |

Power supply | AC220V 50/60HZ |

Wattage | 1.5KW |

Air pressure | 0.45~0.7Mpa |

Air consumption | 30L/min, clean air |

Measurement(L×W ×H) | Approx. 2869mm×1850mm×1214mm |

Conveyor height | 870±30mm |

Weight | Approx. 400kg |

WORKING PRINCIPLE

The label strip from the label roll holder is spread around several guiding rollers, through the dispenser and fixed on the base paper recycle roller lastly. Bottles are fed by a pair of spacing wheels. The clamping conveyor and top conveyor hold the bottles upright when they pass through the labeling section. When the sensor detects the presence of the bottle, it will signal the two label dispensers to stick out a piece of label respectively, which are stripped off by the passing bottle. Then the labels will be pressed closely against the bottle surface by two pairs of sponge roller.

PERFORMANCE

LFLB-3220 is a reliable, high performance machine, designed in conformance with current and proposed GMPs. Having a small footprint. Up to 50 settings memory for various bottle-size labeling tasks. Compact structure, reliable performance and easy adjustment.