당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

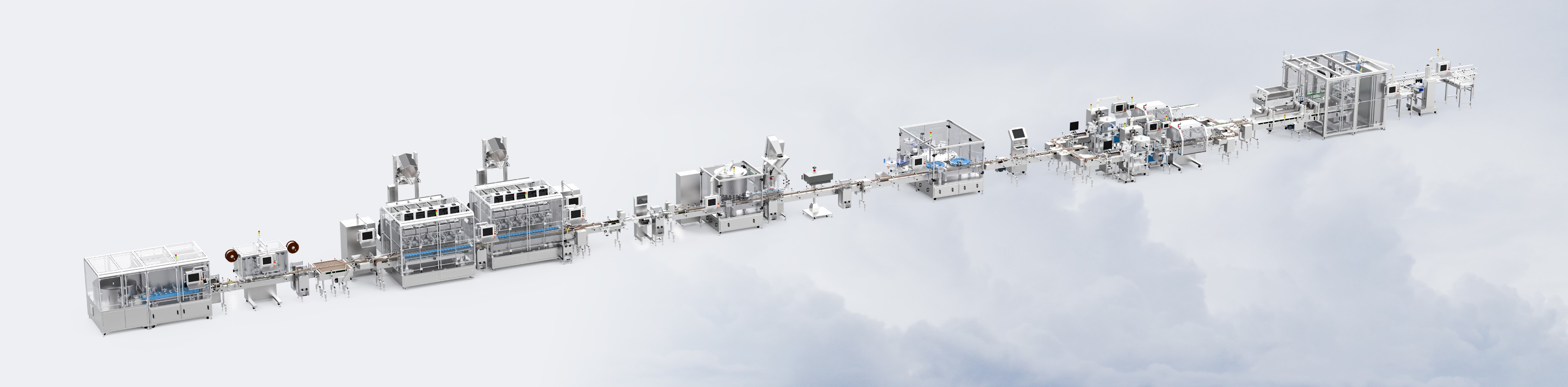

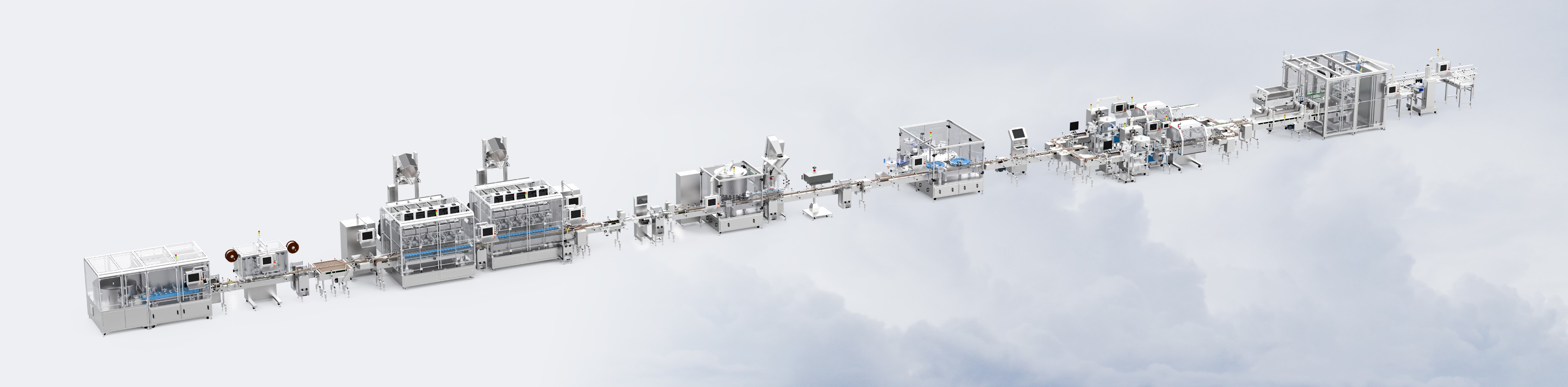

Model | LFLBR-124032 |

Max. label dispensing speed | 60m/min |

Max. Speed | 300 bpm(Depends on the bottle size and label length) |

Bottle size | ¢35-80mmRound bottle,height 60-150mm |

Labeling accuracy | ±1mm |

Power consumption | 5kW |

Power supply | AC220V 50/60Hz |

Compressed air | 0.4-0.7MPa |

Air consumption | 30L/min |

Machine dimension / L*W*H | 5500mm(L)×2616mm(W)×2248 mm(H) |

Machine weight | 3000Kg |

WORKING PRINCIPLE

Bottle comes from upstream to Bottle Infeed Screw, from where bottles are separated evenly and then accurately move to the Star Wheel; Next, the Star Wheel transfers the bottle one by one exactly to every center station of the operation desktop. The operation desktop rotates constantly and drive each station forward and then send bottles to A&B labeling heads for labeling(each labeling head dispenses labels to bottle in the order of 1212) .When bottles are attached with labels, Rotary bottle mechanism makes labels tightly fix on the bottles. Finally, bottles come to Outfeed Star Wheel to next station after well labeled.

FEATURES

1.Machine is under PLC control.

2.The main motor uses German SEW variable frequency stepless speed motor.

3.With power overload protection device.

4.Automatic start with bottle, automatic stop without bottle.

5.Less parts, convenient and quick changeover.

6.The outer frame of the machine is made of stainless steel AISI304 material, which conforms to GMP requirements.

7.Configuration of double UV detection &automatic rejection on missing label.

8.It is optional to equip with hot stamping ribbon printing (E type printer), laser printer, heat transfer printer for the label of the three phase code printing.

9.It is optional to equip with such detection &rejection as three period code printing is clear or not, whether there is printing or not, printing is correct or not.

10.Fast labeling with double headers.