당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

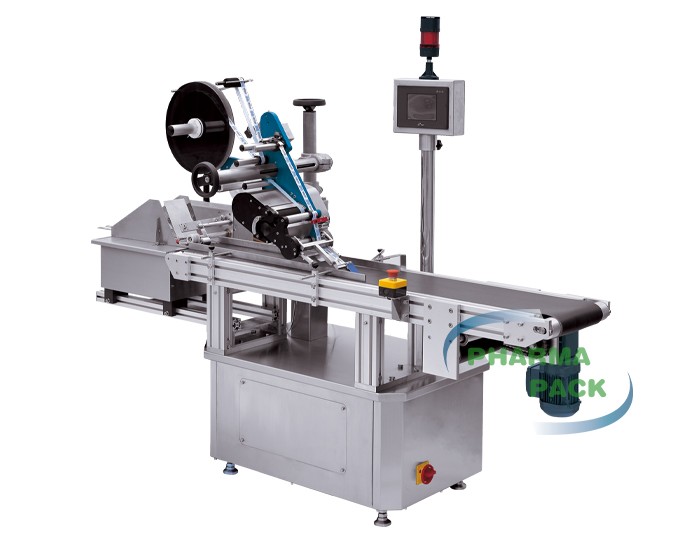

Model | LFLB-4120 |

Max. speed | 200 bpm |

Container size | Width:50-120mm |

Label dispensing accuracy | ±0.2 mm |

Power supply | AC 220V 50-60 Hz, Single or Three Phase |

Power absorption | 1 kW |

Dimension(L x W x H) mm | 1200 x 800 x 1650 |

Working height | 870±30 mm |

Weight | 200 kg |

PERFORMANCE

1、Label dispenser adopts servo motor to drive; dispensing label implements closed-loop control; label dispensing accuracy can be 0.2mm; max. label dispensing speed is 60 meters/min.

2、Label dispenser adopts multidimensional and angle adjustment, to adapt the more labeled objects.

3、Adopt the special control system based on MCU multi point control unit, to make the control accuracy be higher, and be sure that it is easy to deal with the more complex labeling and labeler can receive the control signal from the upper machine in online condition; it is easy and convenient to operate it with human-machine interface on the touch screen.

4、With the storing parameter function, labeler can store about 50 groups of parameter information, to be adjust them conveniently, can reduce time to debug machine when labeler is adopted to product many kinds of products.

5、Label management function: automatically count the quantity and display the used label quantity and the residual label quantity on operation interface.

6、The photo sensibility of the label sensor is adjustable, to adopt kinds of labels with different transmissivity, needn't adjust the position of the label sensor if replace kinds of labels with different length.

7、In working, the object detecting sensor and label sensor aren't interfered by the external light, ultrasonic and another interfering sources; detect precisely to ensure that printing doesn't misplay.

8、The label roll lacking detection, if happen lacking label, the next label covers position in time to avoid omitting label effectively; machine automatically stops after the label roll is used up.

9、The label roll lacking detection, if happen lacking label, the next label covers position in time to avoid omitting label effectively; machine automatically stops after the label roll is used up.

10、The failure displaying function, to help operator eliminating it quickly.

11、The printer with hot ribbon is adapted to print production date, lot number and validity clearly; uninstall and replacing ribbon is convenient, having the alarm function stopping machine after ribbon is used up.

12、The whole machine adopts alnico and stainless steel 304, according with GMP requirements completely.