당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

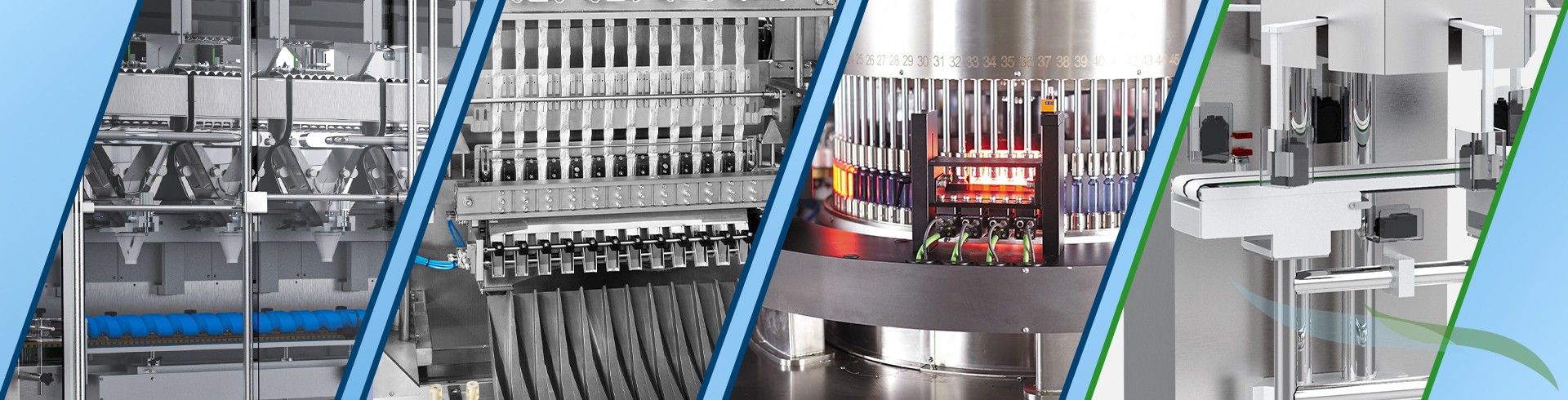

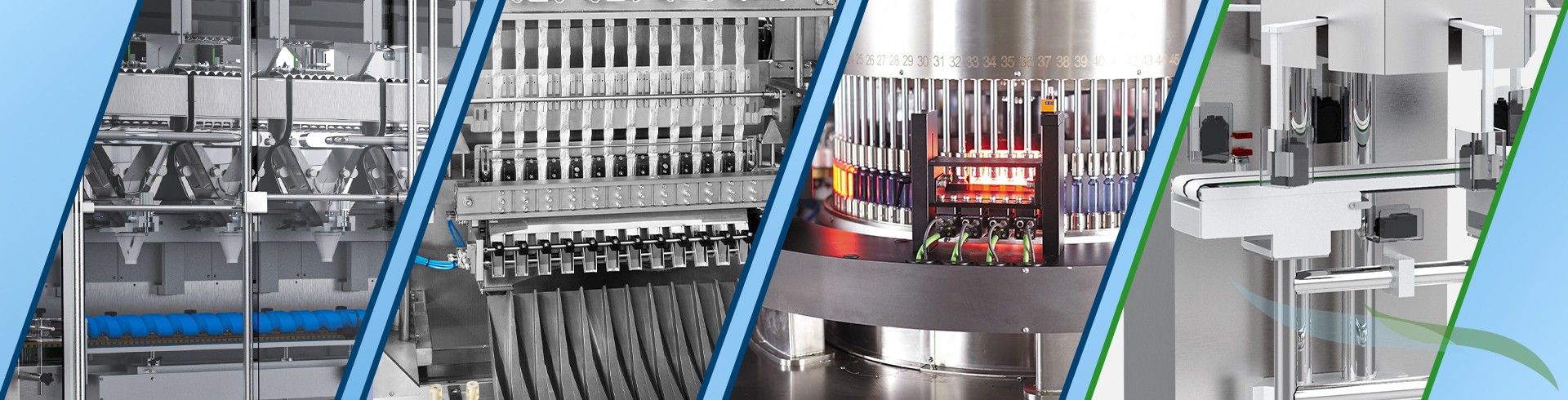

This system especially suitable for factory with limited space. Widely use in pharmaceutical, healthcare, food and confectionery industries.

Track and Trace System for Carton Packaging Lines consist of continuous horizontal cartoner serialization, weight-checking and tamper-evident labeling,

semi-automatic aggregation. It can effectively achieve the process of cartoning, weightchecking & labeling, case packaging & its serializing at high-speed,

Whole line speed to up 250 bottles/min.Compact design, convenient to maintain. This system especially suitable for factory with limited space. Widely use in

pharmaceutical, healthcare, food and confectionery industries.

Product Features

● Serialization, weight checking, coding, and Tamper-Evident labels for your product safety;

● All-in-one camera inspection system can effectively reject defective product on-line;

● Track and trace product and its package (bottle, box, case, bundle, tray and etc.);

● Apply a unique identification code to each product, to trace its own track.

a.Quality tracing management, this helps you quickly trace the source and flow if any problem;

b.Storage tracking management can improve your productivity and data accuracy;

c.Circulation tracking management can quickly implement pre-warning and find out product location;

d.Marketing tracking management helps to trace the after-sale feedback;

● Comply with FDA 21 CFR Part 11 and realize data real-time synchronization;

● Timely and accurately save all information,then generate data chain for circulation tracking and tracing;

● Effectively prevent counterfeit medicine from entering the market and ensure the quality of medicines.