On June 2, Pharmapack was invited to an exclusive interview with the Hong Kong Commercial Daily, in which Pharmapack's corporate culture, mission, and social responsibility were presented in detail. The report has been published in the Special Report Column of the Hong Kong Commercial Daily Guangdong Branch. If you are interested, you can read the report by scanning the QR code below.

Now I'd like to share with you the original text for those who pay close attention to Pharmapack

[Hong Kong Daily Business News] Reporter/Huang Yuyong: As one of the key industries in Guangzhou, there are many leading companies in the intelligent robot and equipment industry. Among them, Pharmapack Technologies Corporation, as a major member of the Guangzhou Industrial Robot Manufacturing and Application Industry Alliance and a Hong Kong-funded enterprise, is the "leader" of China's pharmaceutical packaging machinery industry, firmly occupying the highest position in the domestic high-end manufacturing and packaging machinery industry. According to Pharmapack's director and chief financial officer, Wang Jue, Pharmapack will actively explore the Indian and U.S. markets to expand its global business after delving into the Chinese market.

Pharmapack Technologies Corporation is a successful example of scientific and technological cooperation between Guangzhou and Hong Kong in the field of manufacturing. Pharmapack Asia Ltd. was founded in 2001, focusing on the development, design, manufacture, installation and commissioning of pharmaceutical packaging equipment and after-sales service. In October 2002, Pharmapack (Guangzhou) Packaging Equipment Co., Ltd. was established in Guangzhou Economic and Technological Development Zone, dedicated to providing high-cost packaging equipment and complete packaging production lines for the pharmaceutical industry. Wang Jue said the company has become a leader in the high-end pharmaceutical packaging machinery industry in China.

01 Gain the leading position in the industry with scientific and technological innovation

To become the industry leader, mastering core technologies is key. Wang Jue told reporters that Pharmapack now owns more than 200 patents, including more than 20 invention patents, and has formulated 5 national industry standards in China.

At present, the R&D and Design Center and Production and Manufacturing Base in Guangzhou Economic and Technological Development Zone adopt international advanced technical standards and provide users with production equipment with excellent performance and quality under the support of international procurement networks.

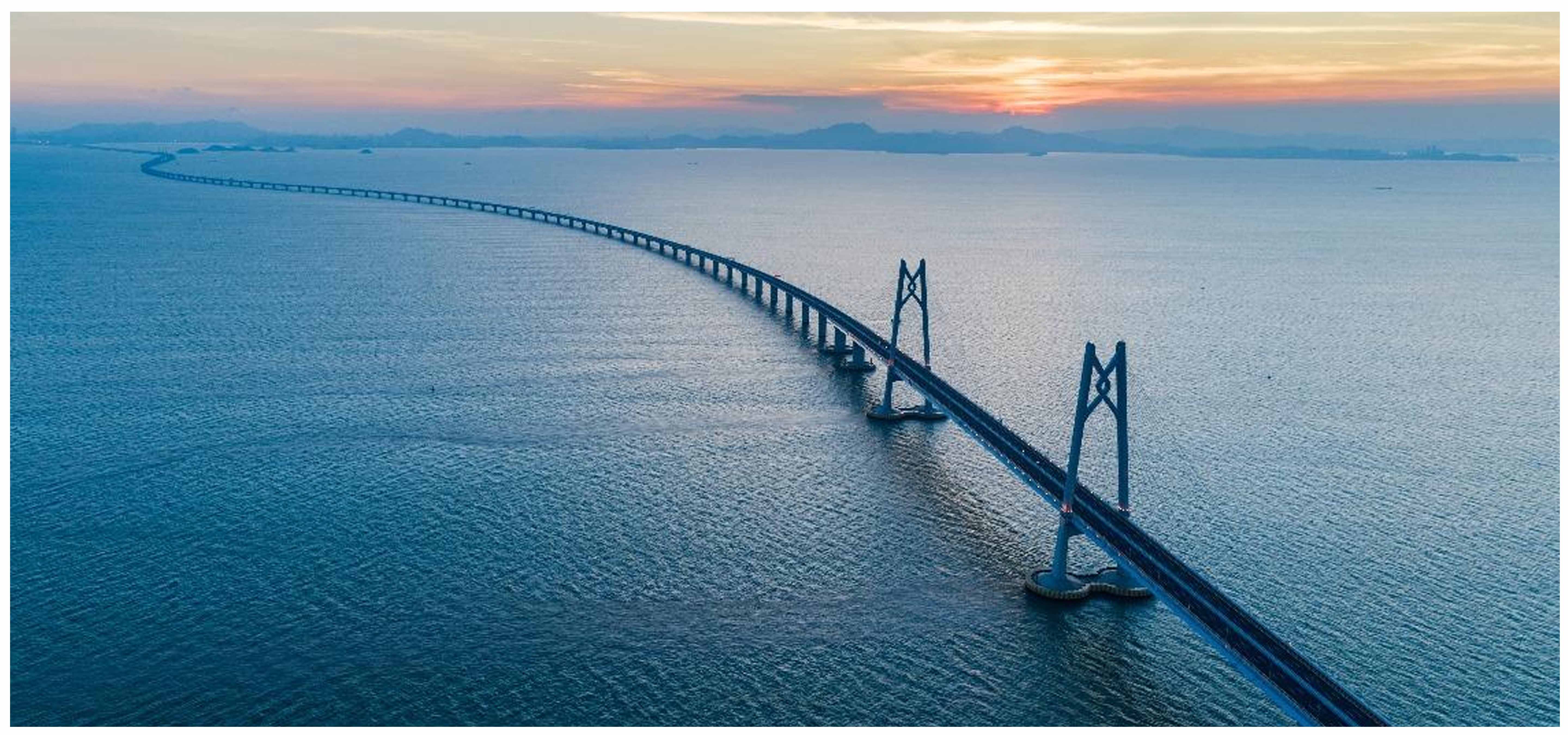

""We have gained a firm foothold in the Chinese market," Wang Jue said. At present, Pharmapack is headquartered in the Chinese mainland market, with branches in Beijing, Shanghai, Guangzhou, Chengdu and Wuhan as hubs, and sales service points in Shenyang, Jinan, Changsha, Xi'an, etc. as support, covering the domestic sales and after-sales service network. The construction of the Guangdong-Hong Kong-Macau Greater Bay Area has provided a wider development space for Pharmapack. Wang Jue revealed that the company will seize the opportunity to build a world-class Greater Bay Area to attract high-level talents who are familiar with Chinese and Western cultures, strengthen the company's industrial design capability, and prepare to be included in the Science and Technology Innovation Board.

02 Expansion of the Indian and American markets with customized products

In the global manufacturing and packaging machinery industry, China, India, and the United States account for 60% of the global market share. After its performance in the Chinese market is stable, Pharmapack has strong demand for international expansion. At present, Pharmapack's business in China and outside China accounts for 60% and 40% respectively, but according to the company's strategic planning, the proportion of its international business will increase to 70% in the next 5 years.

Compared with its global competitors, Pharmapack not only has certain technical advantages, but also has good product cost performance, which is an important guarantee to compete in the international market. In addition, Pharmapack has the ability to manufacture products that can meet individual customer needs, which is far ahead of its overseas counterparts.

It is reported that Pharmapack has established a product lifecycle management model that is executed through conceptual product design, research and development, engineering design, manufacturing, installation and commissioning, and after-sales service, which not only ensures unified industry standards and clear user requirements, it also ensures the potential needs of users' customized requirements and subsequent technical improvement of the products in use. thus establishing a product development mechanism that continuously meets customer needs.

In the Indian market, Pharmapack has established cooperation with top 5 local manufacturers to provide them with highly cost-effective pharmaceutical packaging machinery products.

The United States is, without a doubt, another focus and large market of Pharmapack's global strategy. At present, Pharmapack has also established a wholly-owned subsidiary in the U.S. market. Faced with the potential tariff burden caused by China-US trade frictions, Wang Jue believes that Pharmapack will consider establishing an assembly shop in the United States as a countermeasure, which can not only increase its production capacity, but also provide customers with fast delivery service. "We will not rule out the establishment of a production base in the United States in the future," he said.

[Editor-in-Charge: Zhao Shuqi]