Pharmapack Automatic Capping Machine: Easily Used and Operated

If you are looking for persons good at packaging medicines in bottles, hold your horse! Why bother wasting time and money on time-consuming, costly and fallible humans, when you can simply rely on the machine? In mass production, the automatic capping machine is indispensable for many sectors, especially the pharmaceutical one, where time is essential in the battles against the virus. This guide will brief you on how the automatic capping machines increase your capping efficiency and lower your cost. If you're new in the field, this may be a good start for your further information and purchase of automatic capping machines.

<READ MORE>

So what exactly is an automatic capping machine?

Automatic capping machine is an equipment that places install and tighten lids or caps on different containers faster and better, be them beverage bottles, medicine bottles or any form of container.

All the capper automatically identifies the container and tightens the caps based on their types. The screw capping machine is recommendable for newcomers, as you will soon realize the benefits when you see the increase in production, mainly through accurate torque values. It does help eliminate labor fatigue and prevent unnecessary losses. In a mass production line, much money can be saved if manpower is no longer needed.

In the pharmaceutical industry, high-volume production of drugs delivered in vials and cartridges requires high-speed capping solutions. However, speed must not come at the expense of accuracy and flexibility. Modern high-capacity vial cappers are capable of delivering impressive capacity while maintaining product quality and vibrancy, with the flexibility to seal using screw-on, press-fit, tear-off, and flip-top closures.

Types of Automatic Capping Machines Provided by Pharmapack

There are various types of capping machines to choose. Two things you need to know beforehand are the types of caps and how they are installed. Pharmapack can provide the required capping machines for different capping methods. Pharmapack always has the perfect bottle capping machine for you regardless of which size or shape your caps are.

(BPM: Bottles Per Minute)

Inline Cap Retorquer | 150/200 BPM |

Inline Screw-on Capper | 150 BPM |

Inline Screw-on/Press-on Capper | 150 BPM |

Rotary Capper Machine For Screw Rotary Cap | 150 BPM |

Rotary Capper Machine For Press Rotary Cap | 150/260/400BPM |

1. Inline Cap Retorquer

The LFCL-15/15M In-Line Cap Retorquer is designed to retighten screw-on caps, working at speeds of 200 bottles per minute, maximum. Even more reassuringly, it is built in compliance with current and proposed GMPs.

2. Inline Screw-on Capper

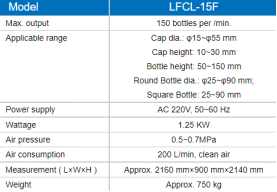

LFCL-15F Inline Screw-on Capper is designed to retighten screw-on caps after induction sealing as speedy as 150 bottles per minute. It utilizes the latest technology to automatically place and precisely torque a wide spectrum of cap types onto virtually any bottles type.

LFCL-15F

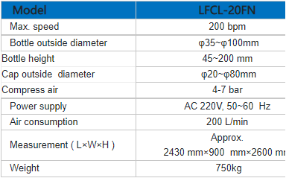

LFCL-20FN Inline Screw-on Capper is perfect for pharmaceutical, healthcare and food industries products. With a specialized device, this machine helpfully tightens the messy caps and bottles sent from the unscrambler to the next step at a certain speed.

Applicable products are cylindrical, elliptical cylindrical, and rectangular plastic bottles between 45~200mm in height and φ35~φ100mm outer diameter. Bottles too large, too small, and not impact resistant (such as glass bottles) are not suitable for this machine.

LFCL-20FN Inline Screw-on Capper cooperates well with our automatic unscrambler, automatic counter, and other filling counting devices, usually connected by a conveyor.

3. Inline Screw-on/Press-on Capper

The automatic capper LFCL-15FN is a reliable, high-performance bottle filling and sealing machine. It is designed in compliance with current and proposed GMPs. Having a small footprint, they are effective in maintaining the integrity of a cleanroom environment. You do not have to alter many parts for different cap sizes, since only the cap slide rail needs to be changed. Bulk caps are loaded into the hopper manually or automatically.

4. Rotary Capper Machine for Screw Rotary Cap/ Press Rotary Cap

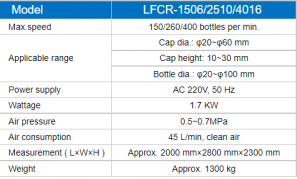

LFCR-1506/2510/4016 for Screw Rotary Cap is specifically useful in the pharmaceutical, healthcare and food industries. It first goes through the cover mechanism by the desired direction of the bottle cap, then into the star wheel of the cap caught by the capping. From the previous process came over the bottle of the spin together to a certain speed to the next process.

Cylindrical, oval, and rectangular plastic bottles between 45~205 mm in height, 20~60 mm outside diameter are all applicable. Those too large, too small, and fragile ones (such as glass bottles) are not suitable for this rotary capper.

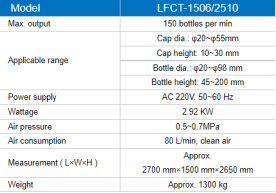

LFCT-1506/2510 Rotary Capper Machine is designed to press on caps after induction sealing, working at speeds of up to 150 bottles per minute. Cap height between 10~30 mm and bottle height between 45~200 mm is applicable. The rotary capper system can handle press-on caps with ease on round or irregular-shaped containers, dealing with as many as 150 bottles per minute. All the caps of φ20~φ55mm and bottles of φ20~φ98mm are welcome for this machine.

LFCT-1506/2510

Why Choose Pharmapack Automatic Capping Machines?

1. Working Fast, Working Much and high volumes of vials and cartridges

Pharmapack never strays from its developmental course of making efficient products. A linear transfer system means higher throughput with fewer feeding problems than other layouts.

2. Accurate, Reliable Capper for Low Loss

Rotary cappers are usually larger, purpose-built machines that will help your company produce more BPM than regular in-line machines. However, if something goes wrong in the production process, many bottles could have been wasted. Worry no more, the Pharmapack rotary capper solves this problem precisely because Pharmapack retorque machines are carefully controlled to minimize errors. The small form factor coupled with the linear design leads to easy maintenance and product changes, reducing the downtime typically associated with these activities.

In Conclusion, Pharmapack Automatic Capping Machine is:

lHigh volume capping and high efficiency

lQuality monitoring including particle, seal pressure, and lid visual inspection

lEase of access reduces the time associated with maintenance and conversion

lFully compliant with GMP standards

Why Choose Pharmapack As Supplier

In the pharmaceutical industry, automatic capping machines are used to seal vials and syrup bottles. The cap seals the bottle to prevent product leakage and spoilage. The choice of capping machine also depends on the shape, size, material, production speed, product nature and sterility requirements of the bottle.

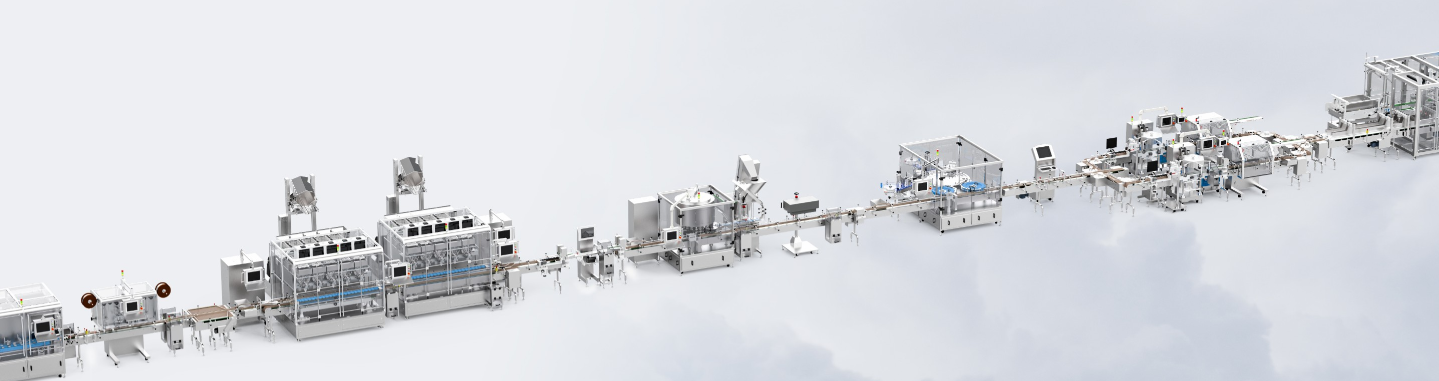

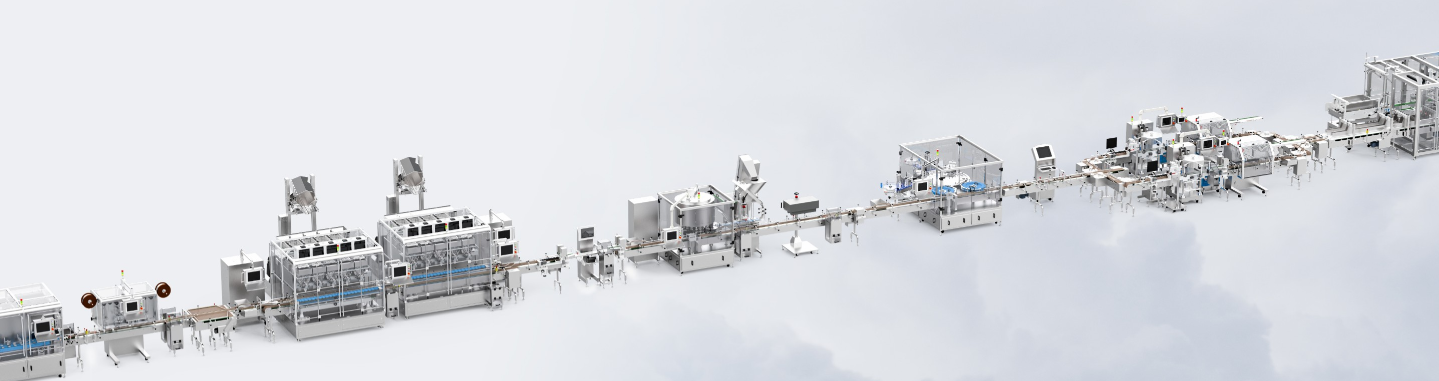

In practical applications, Pharmapck PC series capping machines are usually used in conjunction with other machines, such as automatic bottle loading machines and automatic pelletizers. Pharmapack does not just meet the needs and requirements of filling solid dosage bottles, but also excels in providing half and full customization solutions. Our smart bottle packaging line consists of bottle unscramble, counter, inserter, capper, sealer, labeler, booklet outserter, cartoner, case packer, pelletizer. Our strength lies in our capability to provide standardized, fully customized capping and packaging solution to satisfy customer-specific options or modifications.

Over the past few years, Pharmapack has built a reputation for reliability and innovativeness in its machines and services. Years of experience in the pharmaceutical industry allows Pharmapack to keep pace with increasingly demanding market and trend. Tell us about your production challenges, which line of machines you need to know about, and we will be happy to help you in a detail-oriented, considerate, professional manner. With one-stop solution for your pharmaceutical equipment needs, we are always by your side with good suggestions and solutions.