The function of the cotton inserter:

High speed cotton inserter is a specialized equipment used to inject cotton into various types of containers such as bottles, boxes, and bags, in order to maintain the stability of the products inside the container. It is widely used in industries such as pharmaceuticals, health products, and food.

Working principle of cotton inserter

Manually load the cotton from the cotton barrel into the cotton feeding device and then start the equipment. After the equipment automatically runs, the cotton feeding device feeds the cotton into the tearing roller. When the fed cotton reaches the set length, the fixed length device clamps the cotton, and the tearing roller tears the cotton. The torn cotton flowers are fed into the limit guide groove. When the rotary table sends the cotton duct into the cotton filling station, the lower cotton filling cylinder plugs the cotton from the guide groove into the cotton duct, The rotary table automatically sends the catheter into the next station, and when it reaches the bottle mouth position, the cotton filling cylinder will stuff the cotton inside the catheter into the bottle.

The equipment automatically puts the bottle in position, and at the same time, the previous bottle is stuffed with cotton twice to prevent the cotton from exceeding the bottle mouth and affecting the capping and sealing of the next process; The number of times cotton can be stuffed into each bottle can be set as needed.

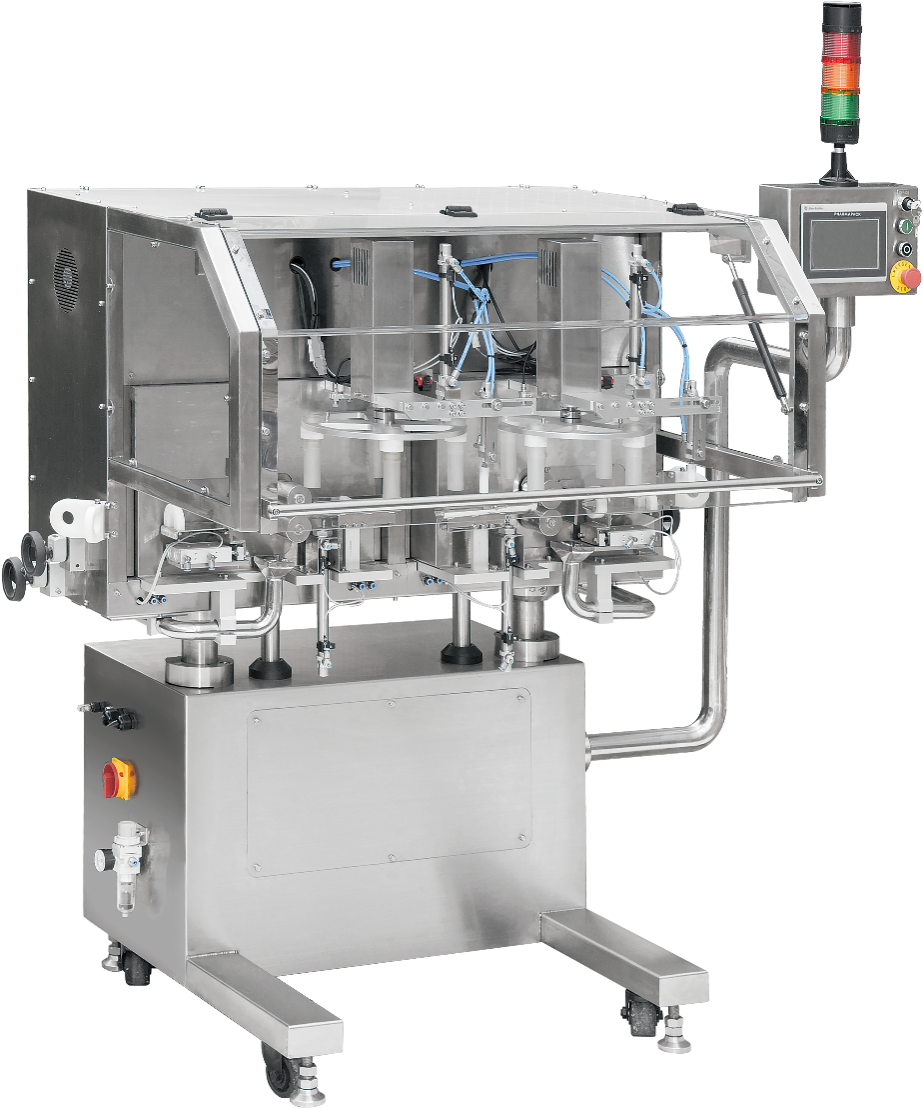

Recommended product: Pharmapack cotton inserter LFIC-20, with a maximum speed up to 200 bottles/minute

Performance characteristics:

1. Compact structure, beautiful and generous appearance, easy to use and maintain;

2. Adopting programmable controller PLC control, Chinese and English interface touch screen, easy to learn and operate;

3. Using a cylinder for cotton feeding and length fixing, with precise tearing length;

4. Multi directional electric eye detection ensures that all cotton is stuffed into the bottle, ensuring that no cotton is placed in the bottle;

5. The workstation turntable adopts servo independent control, with precise positioning to ensure accurate insertion of cotton into the bottle;

6. Using Japanese SMC cylinder plug cotton, the action is crisp, accurate, and reliable;

7. You can set the length of the cotton plug according to the process requirements (length range: 80-160mm);

8. Equipped with secondary cotton stoppage and cotton ultra-high detection function, ensuring that all cotton is stuffed into the bottle or bottles with cotton exceeding the height of the bottle mouth will not flow into the next process;

9. Adjustable frame for bottles of different heights

Pharmapack was founded in 2002 and has 20 years of experience in packaging machinery manufacturing. As a manufacturer of intelligent bottle packaging lines, We always strive to provide customers with practical packaging solutions. If you are considering purchasing Capper , Counter , cotton inserter, or other packaging related machines, we will always be your reliable choice.