Capsule counting machine, as one of the indispensable equipment in the pharmaceutical industry, undertakes the important task of automatic capsule counting and filling. With its high efficiency, accuracy and convenience, this machine plays a huge role in pharmaceutical production lines, greatly improving production efficiency and the standardization level of pharmaceutical packaging.

How it works

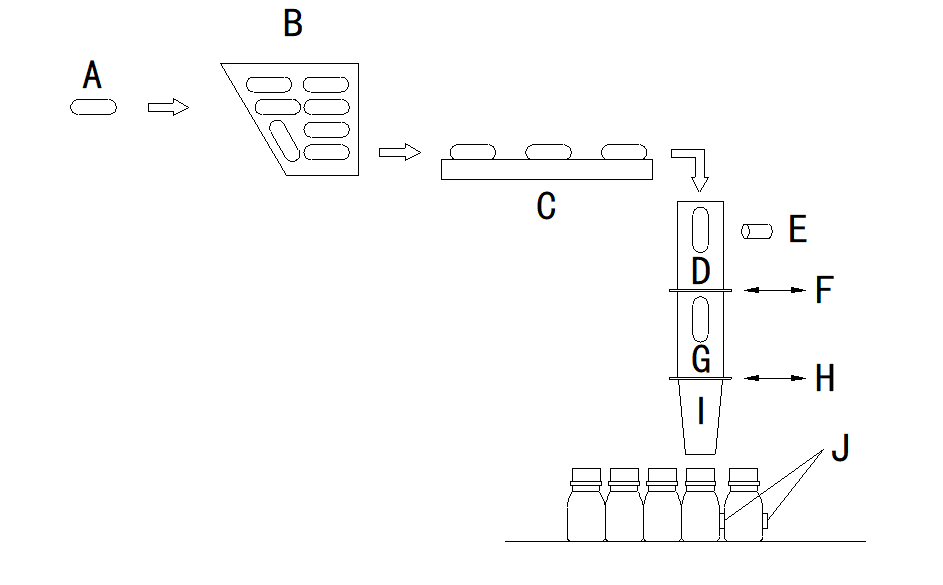

The working principle of the capsule counting machine combines modern electronic technology and precision mechanical design. The operator pours the medicine granules into the hopper on the top of the machine, and uses the vibrating feeder to form a continuous strip along the vibrating groove plate, and then falls into the detection channel one by one. Utilizing the photoelectric effect, the drug particles generate signals when they are scanned by infrared rays, which are processed by a high-speed microprocessor to achieve accurate counting. When the set bottling quantity is reached, the machine automatically stops filling and completes a working cycle.

Comparison between electronic grain counting machine and modular grain counting machine

Compared with traditional electronic grain counting machines, modular grain counting machines show significant advantages in performance:

1. Higher grain counting accuracy ensures the accuracy of pharmaceutical packaging.

2. The machine is designed to have a longer life and is easy to maintain. The alarm system will promptly prompt when a fault occurs, and the modules work independently without affecting the overall efficiency.

3. Not affected by dust, the working speed is stable, and the performance will not be reduced due to machine aging.

Technical advantages of Pharmapack modular pill counting machine LFM-32C:

1. Completely modular design

Each unit is designed entirely based on the modular concept, with a completely independent single-module design. Each single module can be replaced or added or deleted independently; multiple modules can be combined as needed.

2. Complete servo control system

The main material door and small material door controlled by the servo system are faster, more precise and have a longer working life. The servo system and the material door are designed in a separate manner. The material door can be removed separately for cleaning and soaking, making it easier to clean and maintain; and the maximum Reduce noise to a certain extent and fully comply with cGMP requirements.

3. Controlled by servo encoder to ensure synchronous and accurate material receiving;

Synchronized with the screw servo feeding system to ensure synchronous and accurate bottling.

4. Rotating material door

The servo motor is used to rotate the material, which makes the noise lower and avoids the problem of spraying medicine and small medicine particles leaking from the end of the material door when closing the door. It can easily handle small medicine particles with a diameter of 2-3mm.

5. Higher grain counting speed

The innovative vibration unit counts grains faster; the counting speed is 50% higher than that of traditional grain counting machines.

6. Suitable for larger-sized medicines and the number of pills required

The size range of medicines suitable for the maximum number of pills has been increased from the traditional Φ13mm to Φ20mm to better meet the needs of the market.

7. Faster and more convenient maintenance

Completely independent single-module design, the auxiliary trolley can be used to pull out and load the modules that require maintenance separately to achieve quick and convenient maintenance needs.

In the current fierce market competition, Pharmapack insists on taking high quality and innovation as its core competitiveness, and is committed to providing differentiated high-quality products for the grain counting machine industry. If you are interested in Pharmapack's grain counting machine, or are looking for an efficient grain counting equipment, please feel free to contact us at any time and we will serve you wholeheartedly.