In healthcare, accurate pill counting ensures correct medication dosage and patient safety. Historically, manual counting was prone to human error, but tech progressions led to the development of the pill-counting machine. In this article, we will dive into this cutting-edge world and see how these marvels make advancements to enhance accuracy and time efficiency, reducing the burden on healthcare professionals.

Standard vs. Modular Pill-Counting Machine

First, let's discover the two main types of pill-counting machines: standard and modular.

1. Standard Pill-Counting Machine

Standard pill-counting machines have fixed mechanisms to sort and count pills. They use a combination of mechanical gates, vibration trays, and optical sensors for counting. For example, optical sensors can detect the passage of each pill for accurate counts. However, these machines are limited in adaptability. They may require manual recalibration or part changes for different pill sizes or shapes. They surpass in high-volume, repetitive tasks with the constant pill type.

2. Modular Pill-Counting Machine

Modular types offer better adaptability. They incorporate interchangeable parts or modules that can be swapped for different pill types and sizes without extensive manual adjustments. For instance, a modular machine might use adjustable channels or universal feeding trays to be easily reconfigured. It renders them ideal for pharmacies or facilities that handle several medications. Modular designs may integrate innovative technologies, like servo-controlled systems, for reduced noise, improved efficiency, and minimized maintenance expenses.

Techniques Utilized for Making Advancements

The following are the techniques employed to make advancements in pill-counting machines.

1. Vibration Technology

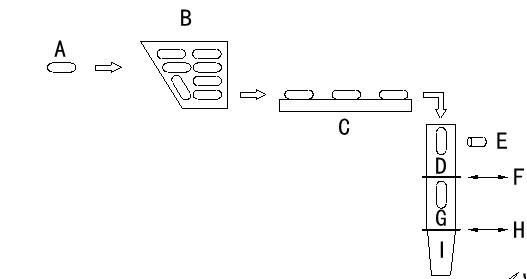

Vibration technology in pill-counting machines relies on controlling mechanical vibrations to align and separate pills. These systems may utilize a vibrating surface or tray to cause the pills to move in a controlled manner. The motion is adjusted using frequency and amplitude controls for pill sizes and shapes. For example, high-frequency vibrations are for smaller pills, so they don't clump together.

2. Optical Detection

Optical detection in these machines uses sensors and cameras to recognize and count pills based on physical characteristics. The electric eye, a common component, is a photodetector that triggers a counting mechanism when a pill passes through its detection area. Progressive systems use machine vision technology. Cameras capture images of pills, and algorithms analyze these images to count and identify different types of pills as per shape, color, and markings.

The development in this domain has seen the fusion of artificial intelligence and machine learning algorithms. These technologies augment the accuracy of pill identification for the machine to learn and adapt to new pill types over time. An example includes systems that can differentiate between tablets and capsules and even classify damaged or broken pills for better counting reliability.

3. Servo-Controlled Technology

Servo-controlled technology employs servo motors to regulate the movement of mechanical components, including gates and channels, through which pills pass. It allows for the accurate handling of pills when directed into containers or packaging. The servo motors' speed and position are controlled by feedback loops for smooth and precise operations.

One of the developments in servo-controlled technology is the assimilation of real-time monitoring systems. They use sensors to track the flow of pills for the servo motors to adjust to changes in pill volume or speed. It is fundamental in automated pharmacy systems with varying pill types and counting speeds.

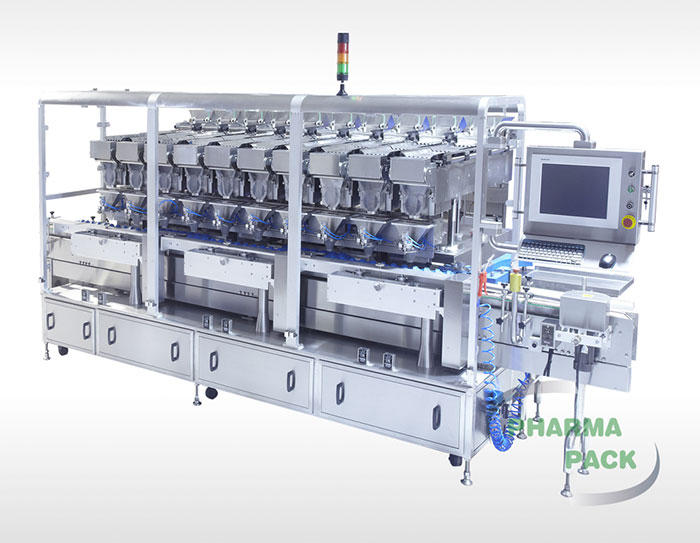

Pharmapack's PP-30LC Follow-Up Modular Granulator

At Pharmapack, we prioritize novelty in pharmaceutical manufacturing. Concerning counters for solid medicines like pills, let's have the PP-30LC Follow-Up Modular Granulator as an example.

This machine offers a speed of up to 30,000 pcs/min, which is adjustable for solid medications like pills, tablets, and capsules. Significantly, its modular design heightens flexibility for easy module replacement or adjustment. Besides, our servo control system with separate flapper and continuous screw servo infeeding confirms precision. Undoubtedly, it is compliant with cGMP standards. We integrate these qualities to produce pharmaceuticals efficiently and accurately, which demonstrates our technical preeminence.

Conclusion

Pharmapack focuses on novel pharma-packing gear. Whether you are looking for pill-counting machines, capsule-counting machines, or tablet-counting machines, we believe we have the right thing for you. Our creative servo control technology decreases repair expenses and increases equipment efficiency and lifetime. Over 1500 smart packaging lines from our extensive pharmaceutical network are available globally. With a record of 300+ patents, we are trusted with our dedication to advancement and worldwide quality standards.