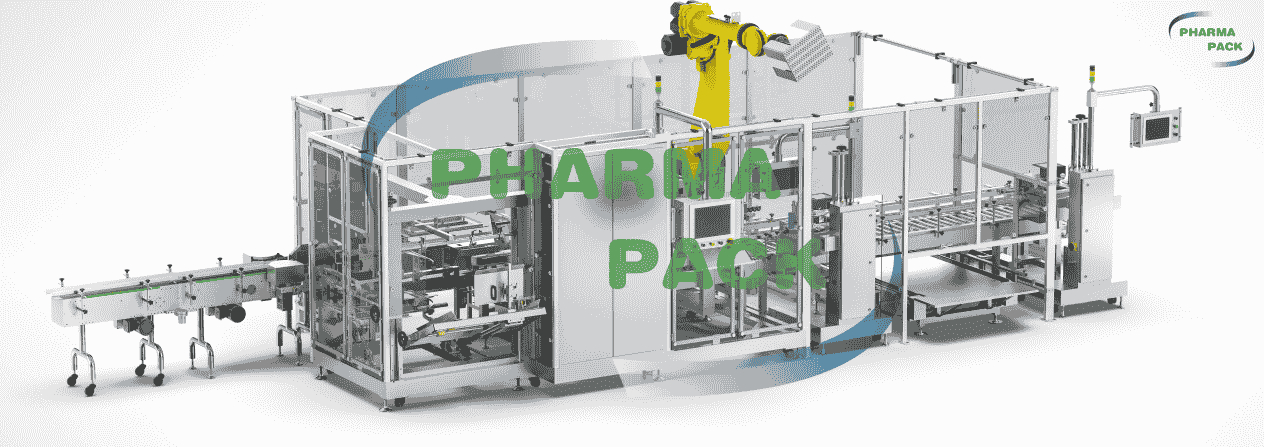

In the rapidly developing industrial era, automation equipment has become the key to improving production efficiency and reducing costs. Packing machine, as an important part of the automated production line, bears the heavy responsibility of product packaging. The following Pharmapack will deeply discuss the design concept, working principle and advantages of vertical automatic packing machine ALFC-04S-02.

The design of the ALFC-04S-02 follows the principle of simplicity and efficiency. Its integrated structure is not only beautiful, but also compact and practical, which can be easily integrated into various production environments. The reserved scanning station also reflects the prediction and adaptation of future intelligent production.

1. Box forming: Through the precision unpacking mechanism, the flat carton is quickly formed into a three-dimensional container, preparing for the next packing.

2. Packing process: accurate grasp of the robot arm, combined with the stable support of the vacuum suction cup and fixture, to ensure that the product is safely and neatly placed in the carton.

3. Packing is completed: the conveyor belt will send the carton filled with products to the sealing mechanism, and the sealing of the transparent adhesive paper is not only firm, but also beautiful.

1. Integrated design, quick adjustment: the integrated design of the silo and the main body enables the ALFC-04S-02 to quickly adapt to different types of cartons.

2. Intelligent control, easy operation: movable touch screen displays the operation interface, making the operation more intuitive and convenient.

3. Efficient packing to increase production capacity: By optimizing the packing process, the ALFC-04S-02 can significantly increase the packing speed and reduce the production waiting time.

4. Customized services to meet diverse needs: optional partition placement and certification coding functions provide more possibilities for the packaging of different products.

From food to pharmaceuticals to cosmetics, the ALFC-04S-02 has proven its superior performance and reliability in a number of industries. ALFC-04S-02 packing machine has been applied to thousands of production lines in different industries, widely praised by customers. Whether it is flexible production requiring rapid replacement of product lines or stable output requiring high-efficiency mass production, the ALFC-04S-02 is capable of doing the job.

Pharmapack vertical automatic packing machine ALFC-04S-02 not only represents the current advanced level of automated packaging technology, but also an integral part of the smart factory of the future. Its emergence not only brings efficiency and cost optimization for enterprises, but also lays a solid foundation for the intelligence and automation of the entire production process. With the continuous progress of technology, ALFC-04S-02 will continue to lead the development trend of automated packaging equipment and provide strong support for the sustainable development of enterprises.