Drug lettering is an essential step in the pharmaceutical process, which provides a unique identifier for drugs and helps to trace important information such as production information, batch number and expiration date of drugs. This lettering operation not only helps business management and quality control, but also helps consumers identify and choose the right medicine.

Laser engraving machine, as an innovative technical solution, has become an important trend in the field of drug labeling. Drug laser engraving machine uses high energy laser beam to write drugs, through computer control, the text, numbers, patterns and other information accurately engraved on the surface of the drug, to achieve the identification and tracking of drugs. The high energy laser beam is used to write the drug, and the information such as words, numbers, and patterns are accurately written on the surface of the drug particle to realize the identification and tracking of the drug.

The selection of pellet laser engraving machine can be considered from the following aspects:

1. Printing accuracy: Printing accuracy refers to the clarity and accuracy of the laser engraving machine to print text and patterns on the pill. Pills are usually small, so high-precision printing technology is required to ensure that the printed content is legible while meeting the requirements of drug regulation. High-precision printing also helps prevent counterfeiting and ensure drug safety.

2. Printing speed: Printing speed directly affects production efficiency. When choosing a laser engraving machine, it is necessary to consider whether the printing speed of the equipment meets the production needs. High-speed printers can significantly improve production efficiency, especially in mass production, but also need to ensure that print quality is not affected by speed.

3. Equipment stability and reliability: Drug production has high requirements for the stability and reliability of equipment. The laser engraving machine needs to maintain a stable working state during a long period of operation to ensure the continuity of production and the qualified rate of the product. The reliability of the equipment is also reflected in the low failure rate, simple maintenance and so on.

4. Compatibility and flexibility: Pellet shapes and sizes vary, so laser engraving machines need to be able to adapt to different types of products. Compatible devices can be easily integrated into existing production lines, while flexibility is reflected in the ability to quickly adjust Settings to suit different printing needs, such as different sizes of pills or different print content.

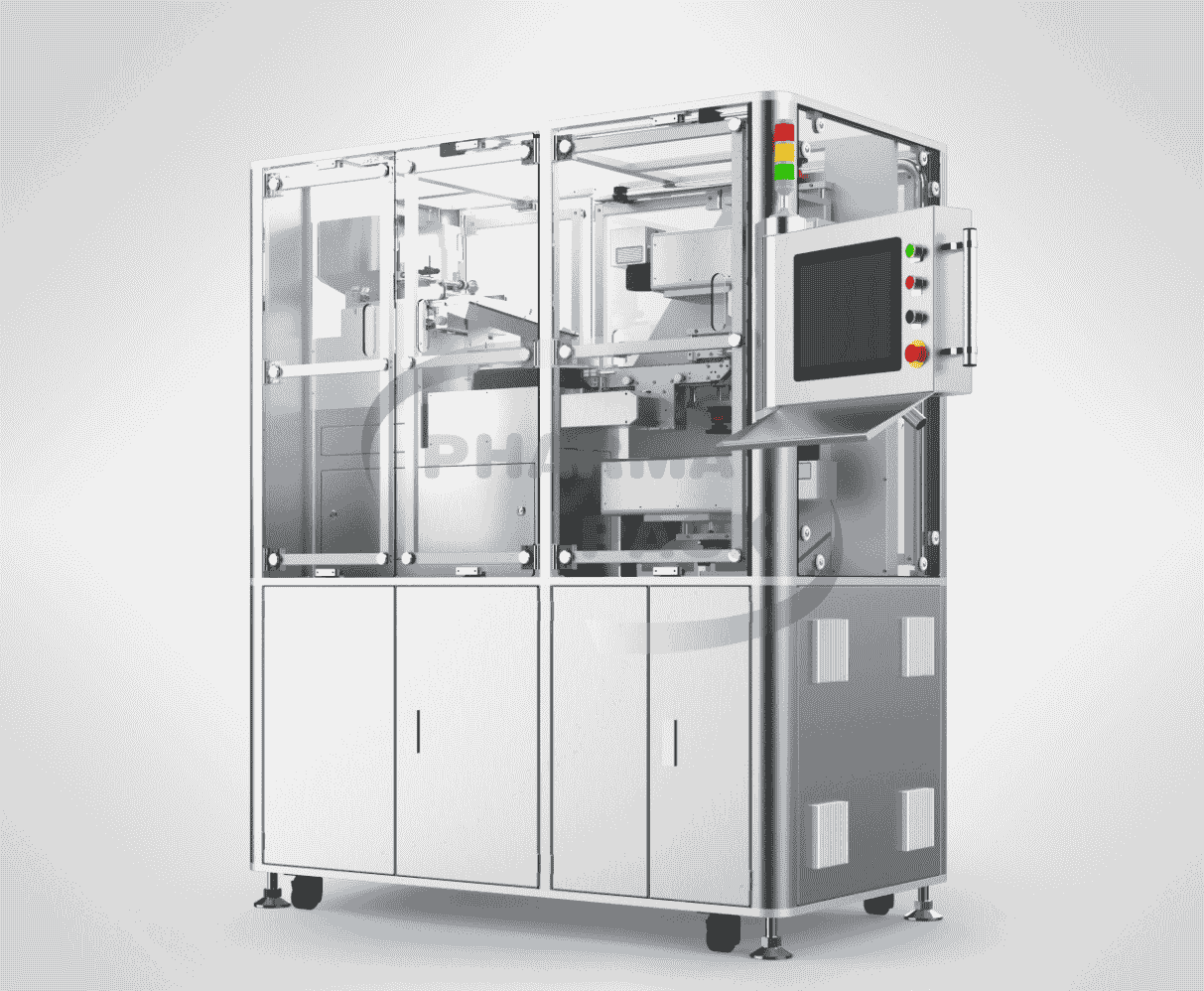

The Pharmapack GLFLP-600 Pill Laser Scribe offers the following advantages as an efficient and reliable solution for pill printing:

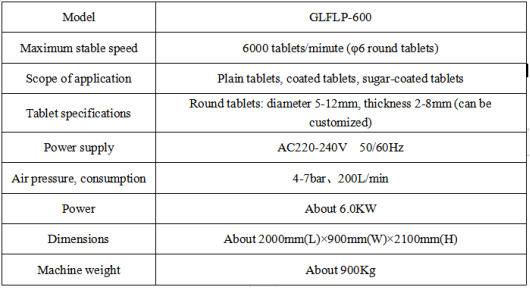

1. High speed and stability: stable speed up to 6000 tablets/min, suitable for 5-12mm diameter, 2-8mm thickness of tablets.

2. High degree of automation: Integrated vibration feeding, material management turntable, adsorption conveyor belt and laser printer and other modules, to achieve double-sided automatic printing of tablets.

3. Advanced control system: adopt integrated motion control module and highly integrated industrial computer control system, easy to operate, easy to debug and maintain.

4. Ergonomic design: pay attention to ergonomic design, with good operability and maintenance.

5. Anti-counterfeiting and traceability: The two-sided printing of the tablets is realized, which improves the anti-counterfeiting and traceability of the tablets.

Drug laser engraving machine plays an important role in improving the traceability of drugs, preventing counterfeit and shoddy drugs, ensuring the safety of patients' medication and promoting the healthy development of the pharmaceutical industry. As an efficient and reliable tablet printing solution,Pharmapack GLFLP-600 pill laser scribe plays an important role in the pharmaceutical industry. If you want to know more about this product, please contact our sales team.