Vision inspection checks items for defects using modern optical and computational methods for quality and compliance with strict industry requirements. Pharmaceutical vision inspection machines use high-resolution cameras and leading algorithms to identify minute packaging, labeling, and tablet integrity issues. Cracks, contamination, and erroneous labeling are also detected for patient safety and regulatory compliance.

The importance of such a camera vision inspection system speaks for itself. This article will lead you through important aspects of this vital inspection machine, helping you master critical knowledge!

Components of Vision Inspection Machines

1. Cameras and Sensors

Cameras and sensors are the key parts of a vision inspection machine. High-resolution cameras record goods under inspection, and image sensors will detect the light signal and transform it into a digital representation.

CMOS or CCD sensors are possible components utilized. CMOS sensors are fast and low-power, while CCD sensors may provide better image quality and sensitivity. Also, 3D sensors use laser triangulation or structured light to capture surface topology for precise dimensional measurements.

2. Lighting Systems

Lighting systems are important in vision inspection machines since they guarantee steady illumination for accurate image capture. Many lighting techniques are used, including backlighting, ring lighting, and coaxial lighting. For instance, backlighting highlights the edges, making edge defects more visible. Meanwhile, coaxial lighting is particularly used for inspecting highly reflective or mirror-like surfaces.

3. Image Processing Software

Image processing software is the brain of a vision inspection machine. It uses algorithms to examine images and detect deviations. Techniques like blob analysis, pattern matching, and edge detection might be employed. For example, CNNs are used in more unconventional systems for their ability to learn and spot multifarious patterns. Moreover, software integration with ML allows unremitting improvement in defect recognition accuracy while learning from new data.

4. Control Systems

Control systems manage the operations of a vision inspection machine. They coordinate the interaction between cameras, sensors, lighting, and reject mechanisms. PLCs are widely used due to their fidelity and real-time processing abilities. They execute inspection sequences, handle I/O operations, and connect with other machines in production. Furthermore, control systems can adapt real-time inspection parameters according to performance feedback under varying conditions.

5. Reject Mechanisms

Reject mechanisms remove defective items recognized by the vision inspection machine. They use methods, including pneumatic ejectors, diverters, or robotic arms. Pneumatic ejectors are quick and suit high-speed lines. Robotic arms provide precision for delicate items. Integration with image processing software confirms that rejection is timed and positioned. It disregards false rejects and guarantees that only malfunctioning products are removed from the production line.

Vision Inspection Machines in the Pharmaceutical Industry

The above talks about the critical components of a visual inspection machine. Now, the following will discuss what these inspection machines can do!

1. Component Inspection

Camera vision inspection systems are vital in pharmaceutical manufacturing/packaging to examine tablets, vials, and liquids. They can identify tablets with irregular shapes or sizes, ensuring only those meeting precise specifications are approved. Sophisticated algorithms enable the detection of surface defects, chips, and color variations.

Additionally, vision inspection machines can sense microscopic cracks or scratches that could compromise the sterility of vials. Besides high-resolution cameras and algorithm analysis, they can be integrated with other technologies, like high-pressure leak detection. Together, these machines safeguard component integrity for reliable pharmaceutical products.

2. Label and Packaging Quality

During pharmaceutical labeling and packaging, vision inspection machines can also play a critical role. These machines may use OCR and OCV to verify label text accuracy and readability. They can spot misalignments, smudges, or print defects, so labels contain correct and legible information. Apart from that, the machines inspect the packaging for defects, including improper sealing, misfolding, or incorrect assembly. With machine learning algorithms, visual inspection machines advance detection accuracy and adapt to new packaging standards.

3. Filling Level Verification

For liquid medication, including oral solutions and injectable solutions, visual inspection machines participate in the packaging line to ensure dosage accuracy. Technologies that can be utilized include machine vision systems, AI visual inspection, industrial cameras, and more. They detect underfilled or overfilled containers with high precision. While integrating with production lines, vision inspection machines provide immediate feedback for product consistency.

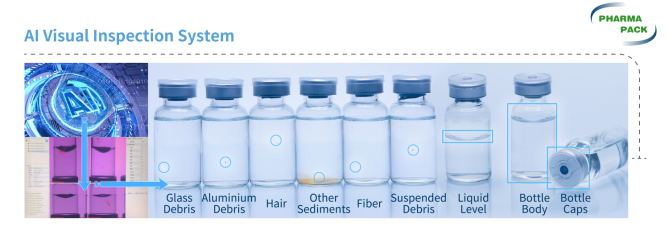

4. Foreign Object Detection

Foreign matter detection is another important functionality of visual inspection machines. Specifically in liquid pharmaceuticals, there can be impurities, such as glass particles, aluminum shavings, and fibers. They may be as small as a few micrometers, but they can influence the pharmaceutical's effect. A leading visual inspection machine ensures that only contaminant-free products can reach consumers for effective treatment.

Inspection Machines from Pharmapack

At Pharmapack, there are inspection machines that utilize top camera vision inspection systems. Take LFIM – 60/84 Continuous Inspection Machine, for example.

These two models (LFIM-60 and LFIM-84) are particularly designed for inspecting ampoules, vials, oral solutions, and more. They detect the condition of the bottle and the liquid, including:

l Bottle cap, body, and bottom

l Liquid purity and level

These inspection machines employ high-solution cameras that capture 300 frames per second. Each of them is equipped with a high-speed DSP image processing system, improving productivity significantly. (LFIM-60: 450 BPM maximum; LFIM-84: 800 BPM maximum)

Higher efficiency comes with stable performance. The use of servo-controlled in-feeding screws and star wheels, complemented by vacuum assistance, ensures a seamless and gentle transfer of vials or ampoules, significantly minimizing the risk of damage during the process.

Conclusion

Pharmapack is a pharmaceutical packaging machine manufacturer that focuses on innovation and improvement. With talented engineers and experts, Pharmapack possesses more than 400 invention patents. In addition to vision inspection machines, we also develop pharmaceutical equipment, including bottle unscramblers, labeling machines, and stick-pack machines. Contact Pharmapack if you are looking for top-rated packaging machines. You can also enjoy our professional custom services to have the right packaging equipment!