In the packaging industry, the sealing process is crucial. It not only affects the appearance of the product but also directly impacts its sealing and safety. Traditional sealing methods, such as heat sealing and ultrasonic sealing, have their own characteristics but also limitations, making it difficult to meet the high efficiency and quality requirements of modern production lines.

Pain Points of Traditional Sealing Methods:

1. Low Efficiency: Traditional sealing methods often require manual operation or cooperation with other equipment, resulting in low efficiency and unable to meet the needs of high-speed production lines.

2. Unstable Quality: Affected by factors such as the skill level of operators and ambient temperature, the quality of sealing is difficult to guarantee, and issues like air leakage and liquid leakage are prone to occur.

3. Poor Applicability: Different packaging materials and containers require different sealing methods, and traditional sealing equipment often cannot meet various needs.

The electromagnetic aluminum foil sealer is an ideal choice to address the pain points of traditional sealing methods with its efficiency, stability, and safety.

1. Efficient Sealing, Time and Labor Saving

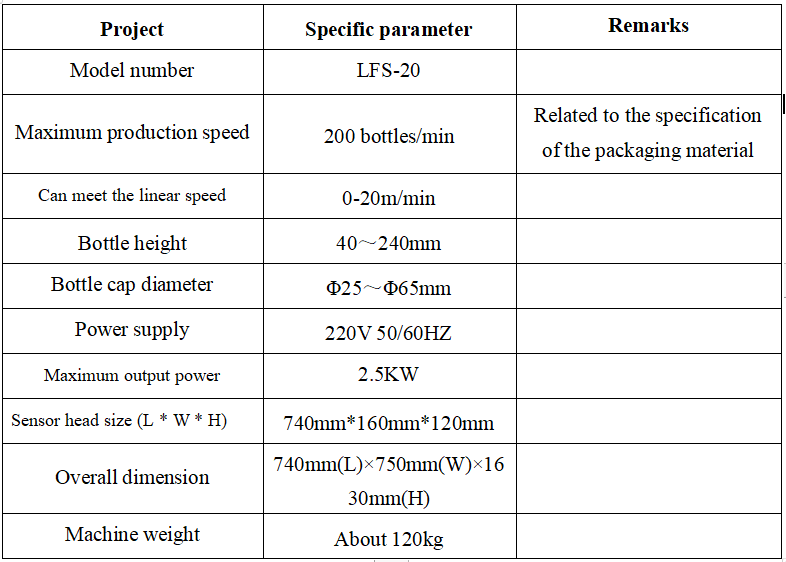

The electromagnetic aluminum foil sealer utilizes electromagnetic induction technology to heat the aluminum foil rapidly through eddy currents generated by high-frequency current, achieving a tight bond with the bottle opening for efficient sealing. With a maximum production speed of 200 bottles per minute, it can meet the efficiency needs of different production lines, significantly improving production efficiency and reducing production costs.

Equipped with an intelligent control system, the machine can precisely control sealing parameters such as temperature and time, ensuring the consistency and stability of sealing quality. It effectively prevents issues like air leakage and liquid leakage, guaranteeing product quality and consumer safety.

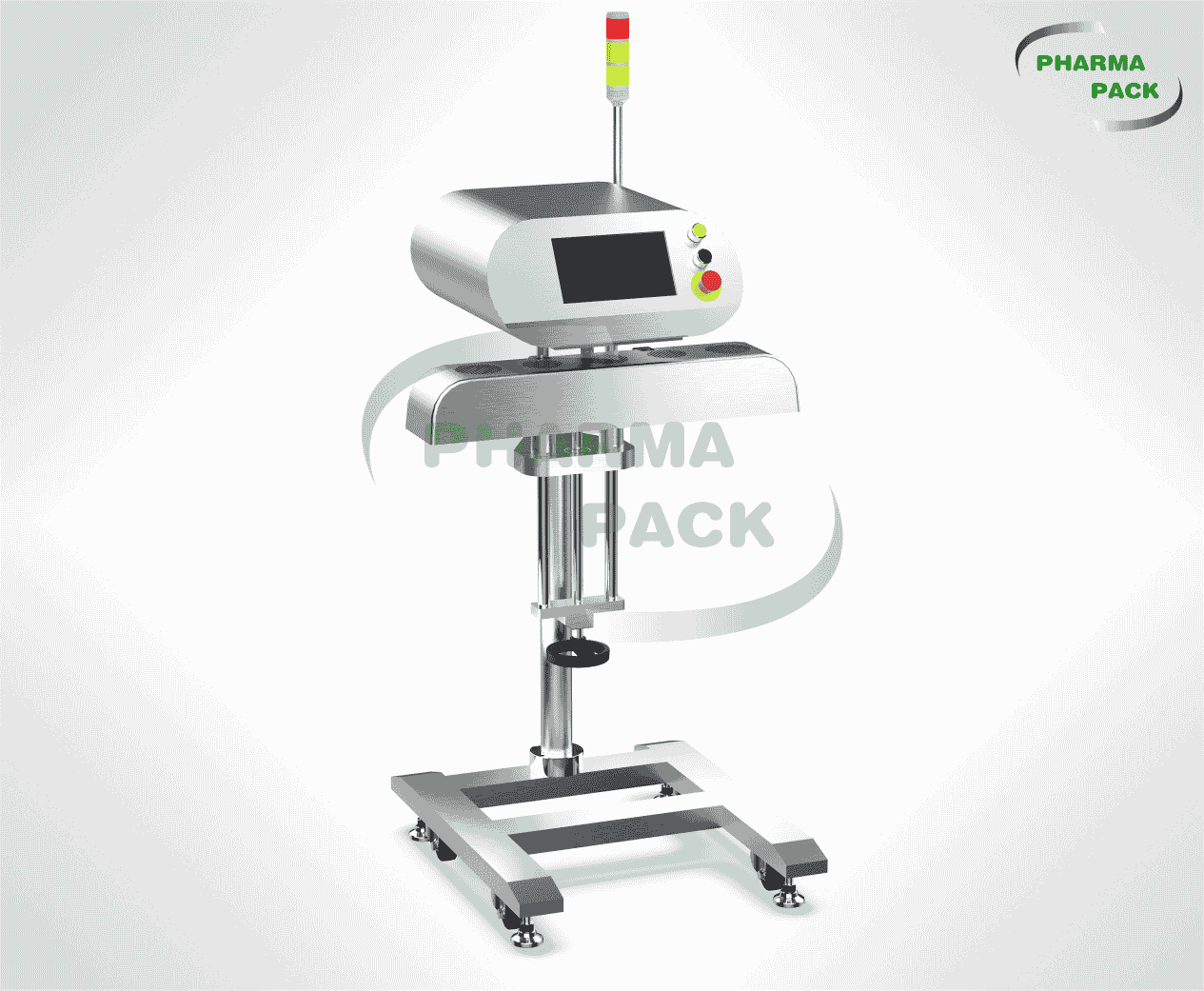

The LFS-20 electromagnetic aluminum foil sealer can be used for various container materials, including polyethylene (PE), polypropylene (PP), polystyrene (PS), polyester (PET), ABS, as well as glass and ceramics (excluding metal bottles and caps). Its adjustable frame with screw and nut structure allows easy height adjustment to accommodate different-sized packaging containers, meeting diverse sealing needs.

The machine features an intelligent design with functions like moisture-proof, corrosion-proof, dust-proof, and magnetic interference prevention, resulting in low failure rate and simple maintenance. Additionally, equipped with air-cooling heat dissipation system and power module, it operates efficiently for 24 hours and automatically alarms in case of failure, ensuring safe and reliable operation.

The LFS-20 electromagnetic aluminum foil sealer is equipped with data collection functionality, monitoring the machine's operating status, alarm status, power, current, and other data, helping users to understand the machine's operating conditions in real-time and enabling intelligent management to improve production efficiency and management level.

Choosing the right sealer is a key step for companies to enhance their competitiveness. If you want to learn more about the LFS-20 electromagnetic aluminum foil sealer, please contact us.