Traditional packaging methods can no longer meet the increasing production capacity demands and strict pharmaceutical packaging standards. To keep up with the growing production demands and meet more stringent packaging standards, pharmaceutical companies urgently need equipment that can both increase packaging speed and ensure packaging quality.

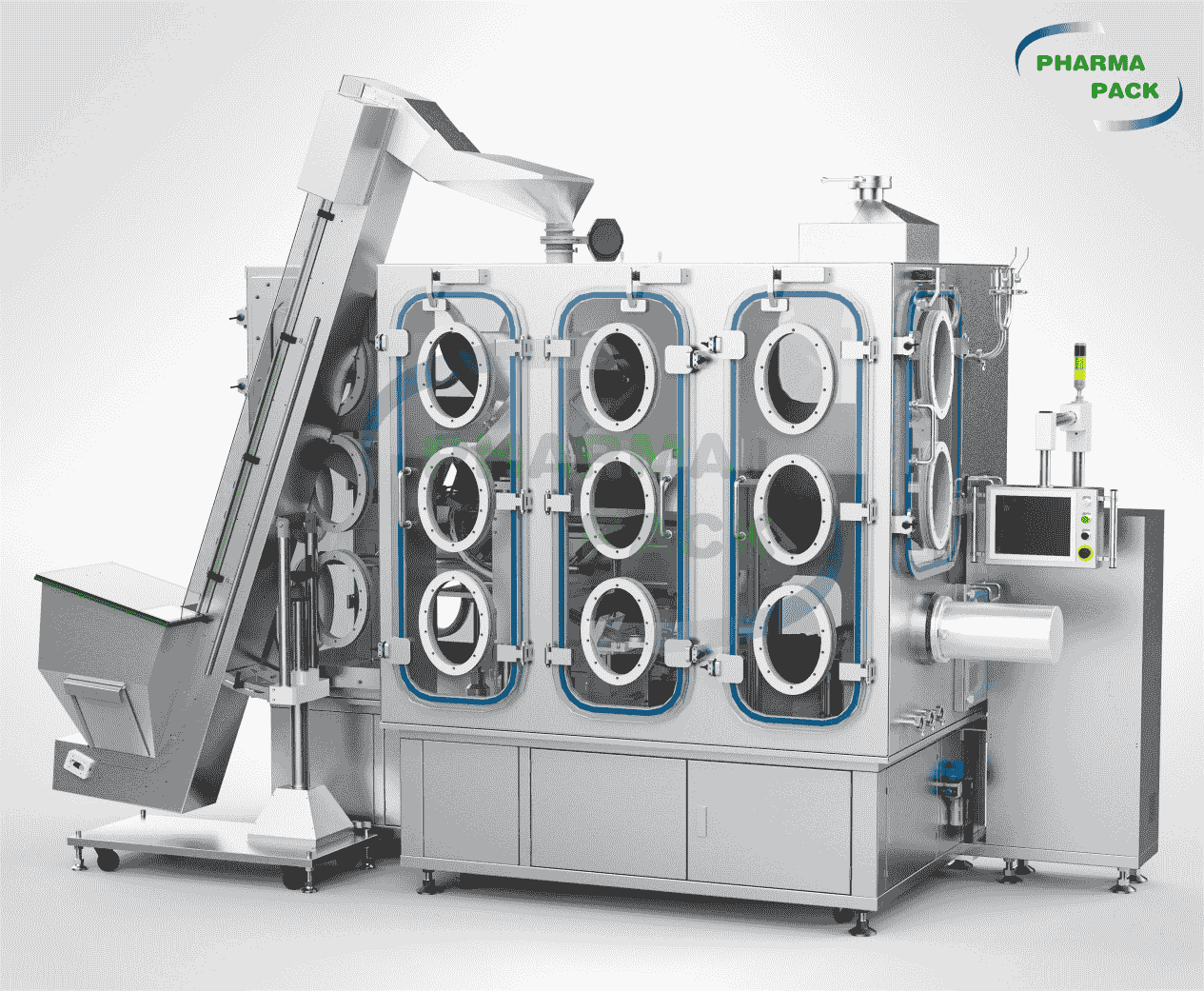

The Counting and Capping Integrated Machine, as an advanced automated packaging equipment, creates a negative pressure within the working space through a sterile isolation cover and exhaust system to prevent external contamination, avoid contact with operators, and is suitable for professional counting and filling of easily contaminated, moisture-prone, toxic, and corrosive pharmaceuticals.

1. Increase in production capacity demand: As the population ages and health awareness improves, the demand for pharmaceuticals continues to grow, posing higher requirements for pharmaceutical packaging capacity.

2. Stricter packaging standards: Pharmaceutical packaging not only needs to meet basic protective functions but also comply with various requirements from drug regulatory authorities, such as moisture resistance, anti-counterfeiting, and ease of identification.

3. Clear trend towards automation: Automated packaging equipment can effectively improve production efficiency, reduce labor costs, and ensure product quality stability, becoming a development trend in the pharmaceutical packaging industry.

The Counting and Capping Integrated Machine combines counting, filling, capping, and other functions into one, capable of automatically completing the entire pharmaceutical packaging process, with the following significant advantages:

1. Efficient production: The machine uses an automated control system to achieve high-speed counting, filling, and capping, significantly improving production efficiency and meeting large-scale production needs.

2. Accurate counting: The equipment uses advanced counting technologies, such as photoelectric sensing and weighing, to precisely control the number of pills, ensuring packaging accuracy.

3. Stable quality: Automated equipment ensures the stability and consistency of the packaging process, reducing the impact of human factors on product quality, and ensuring the safety and reliability of pharmaceutical packaging.

4. Cost reduction: The Counting and Capping Integrated Machine can replace manual operations, reduce labor costs, and decrease pharmaceutical waste, thus lowering production costs.

5. Flexible application: The machine can be adjusted flexibly according to different pharmaceutical specifications and packaging requirements, adapting to various production scenarios.

Pharmapack, as a professional pharmaceutical packaging equipment supplier, offers a variety of high-performance Counting and Capping Integrated Machines to meet the production needs of different enterprises:

LF-0601CR: The LF-0601CR Monoblock integrated machine operates at an efficient speed of 60 bottles/minute, suitable for precise counting and packaging of pills, tablets, soft and hard capsules, etc. Equipped with infrared dynamic electronic scanning technology, it achieves precise counting and has an automatic rejection system to eliminate counting errors, ensuring an accurate and efficient packaging process.

LF-0601CD: Operating at an efficient speed of 60 bottles/minute, it is suitable for precise counting and packaging of pills, tablets, soft and hard capsules, etc. Using advanced technology to ensure accurate counting and equipped with an automatic rejection function. It features a vibratory feeding mechanism and a dual-gate structure to effectively solve the problem of bottle neck obstruction and increase the filling speed.

LF-0601C: The Counting and Capping Integrated Machine creates a negative pressure within the working space through a sterile isolation cover and exhaust system to prevent external contamination and avoid contact with operators, suitable for professional counting and filling of easily contaminated, moisture-prone, toxic, and corrosive pharmaceuticals.

Pharmapack's Counting and Capping Integrated Machine is an industry tool for enhancing pharmaceutical packaging efficiency. It helps businesses achieve efficient, accurate, and stable pharmaceutical packaging, reduce production costs, improve product quality, and enhance market competitiveness. If you are looking for top-tier packaging machines, please contact Pharmapack. You can also enjoy our professional customization services to obtain the right packaging equipment!