In the pharmaceutical industry, the quality and efficacy of drugs are the guarantee of patients' life and health. The accurate dosage of medication is the foundation of all this. For patients, the appropriate dosage is the key to treatment; too much or too little can affect the therapeutic effect and even threaten lives.

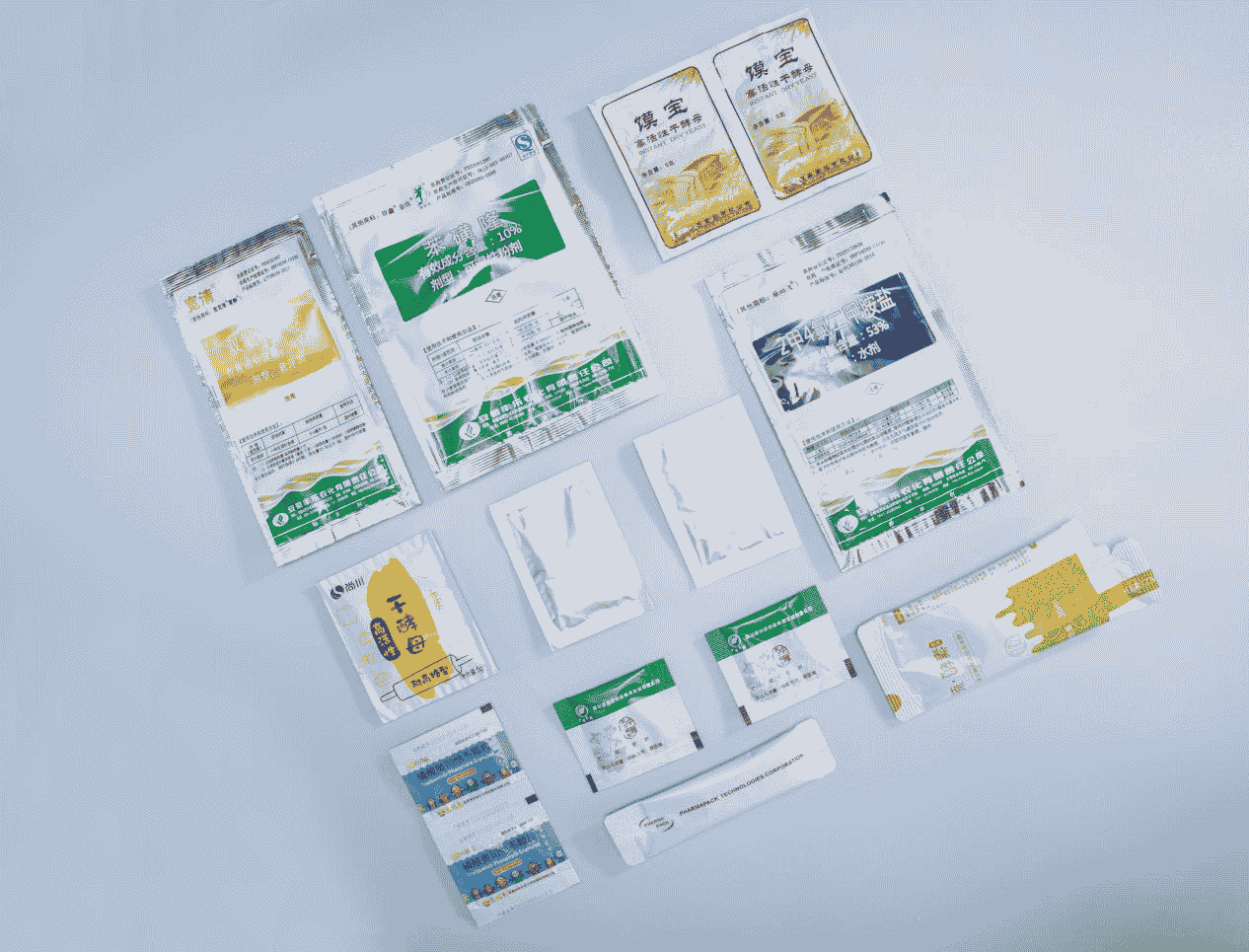

Therefore, ensuring that the weight of different specifications of drugs such as tablets, powders, liquids, and pills meets the standards throughout the entire production and packaging process is a crucial step. This is not only related to the efficacy and safety of the drugs but also demonstrates responsibility to consumer health. It also plays a decisive role in maintaining the market image and reputation of pharmaceutical manufacturing companies.

According to relevant data, the problem of inaccurate medication dosage accounts for a significant proportion in medical accidents, exceeding 30% of the total number of drug accidents. This data not only reveals the importance of drug dosage precision but also reflects the severe challenges faced by pharmaceutical companies in the drug production process.

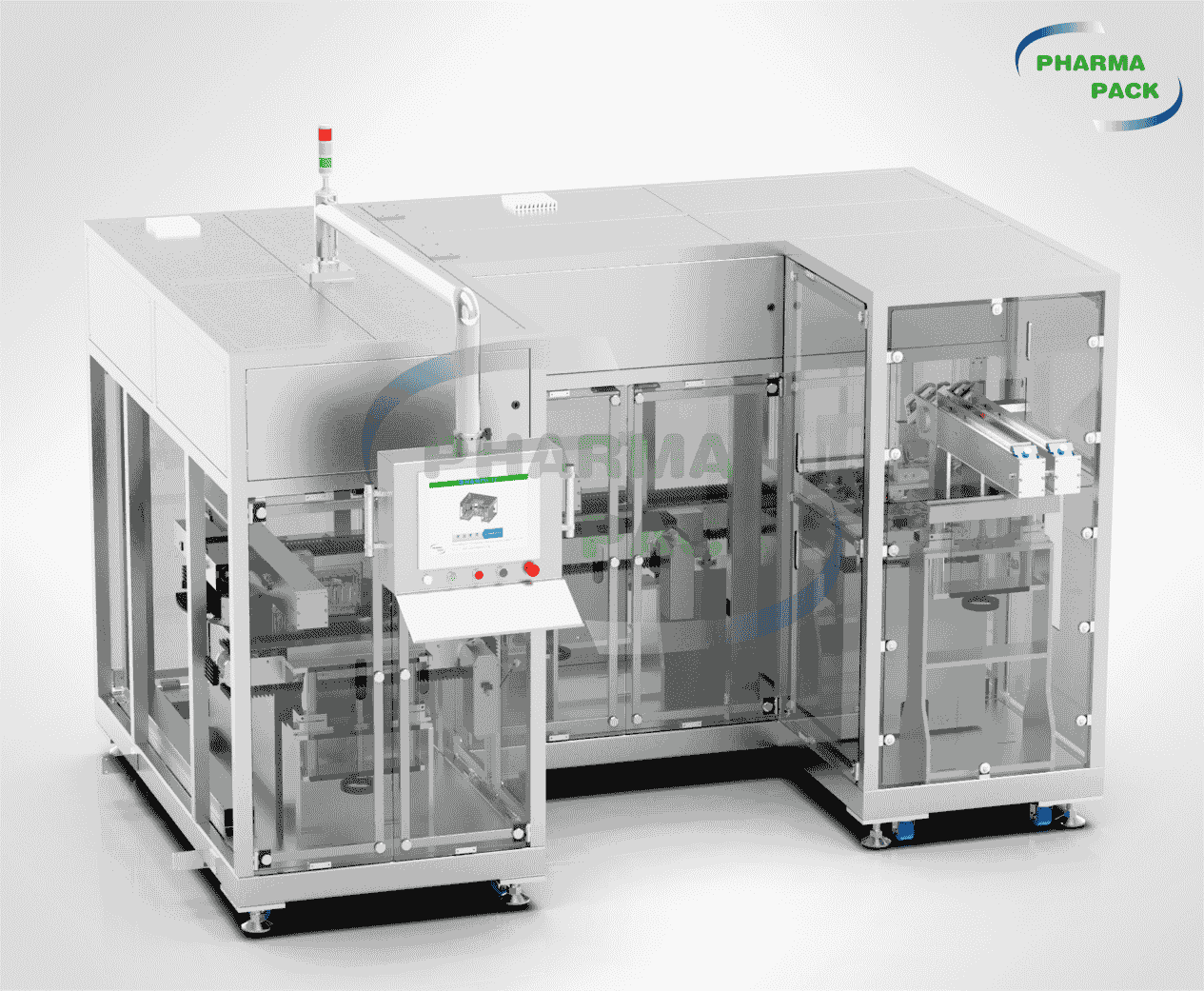

Against this backdrop, Pharmapack recognizes the key role of weight checking and stick re-arrange devices in the drug production process and is committed to developing efficient and accurate equipment. For this purpose, Pharmapack has launched a series of machines such as the 10-column strip packaging weighing machine LFSS-10WT, providing pharmaceutical companies with a comprehensive solution to address the issue of drug weight checking and re-arrangement.

1. Improve production efficiency: The weight checking and stick re-arrange device adopts an automated production line, greatly improving production efficiency and reducing labor costs. In the fierce market competition, efficient production capacity helps pharmaceutical companies seize market share.

2. Ensure product quality: The device features high precision and stability, ensuring that the weight of each tablet is accurate and error-free, reducing the rate of defective products and improving product quality.

3. Reduce risk: Proper medication dosage is crucial for treating diseases. For patients, an excessive dosage may lead to aggravated side effects or even threaten lives; an insufficient dosage may fail to achieve the therapeutic effect and delay the condition. By using the weight checking and stick re-arrange device, pharmaceutical companies can monitor drug weight in real-time, detect and remove unqualified products promptly, and reduce the risk of medical accidents caused by inaccurate dosages.

4. Avoid product recalls, enhance corporate image, and improve economic benefits: By precisely controlling product weight, companies can effectively reduce the risk of product recalls due to weight issues, protect brand reputation, and achieve significant economic benefits, such as reducing raw material waste and production costs, improving production efficiency and market competitiveness, and ensuring compliance with regulations. These measures collectively help boost consumer confidence, thus enhancing the corporate image in all aspects.

1. Improved ease of operation: The device uses industrial control computers and touch screens for operation, allowing for intuitive parameter adjustment through menu clicks, simplifying the operation process, and improving work efficiency.

2. Precision filling control: When used in conjunction with Pharmapack's strip packaging machine, real-time feedback of weighing data achieves automatic adjustment of filling volume, ensuring product accuracy and improving product quality.

3. High-precision detection: Equipped with German HBM thousandth sensor, the detection precision reaches ±0.02g, with overload protection, ensuring the accuracy of weighing data and the safety of the equipment.

4. Flexible sampling function: Integrated manual and automatic sampling functions, with adjustable sampling time, meet different production needs, and improve the adaptability of the production line.

5. Quality assurance: Implementing single-column rejection function, automatically excluding unqualified products to ensure the overall quality of the final product.

6. Real-time monitoring: The operation screen uses a tablet computer for control, with weighing data displayed in real-time, making it easy for operators to monitor the production status and adjust the production process promptly.

7. Compliance with regulations: Integrated with a standalone SCADA function, meeting 21CFR requirements, achieving product traceability and facilitating enterprise quality management and regulatory compliance.

8. Transmission stability enhancement: the anti-overshoot device adopts the front stop and back shift mode, which effectively prevents the movement of the strip package due to inertia in high-speed production, ensures the orderly transmission of the strip package, and improves the stability of the production line.

In summary, in the pharmaceutical industry, accurate medication dosage is the key to treatment and the cornerstone of high-quality development for pharmaceutical companies. As an important equipment to ensure the weight qualification of drugs, the weight checking and stick re-arrange device has become an indispensable choice for pharmaceutical companies. By introducing this device, pharmaceutical companies can not only improve production efficiency and reduce risks but also enhance product quality and corporate image, providing patients with higher quality and safer medical services.