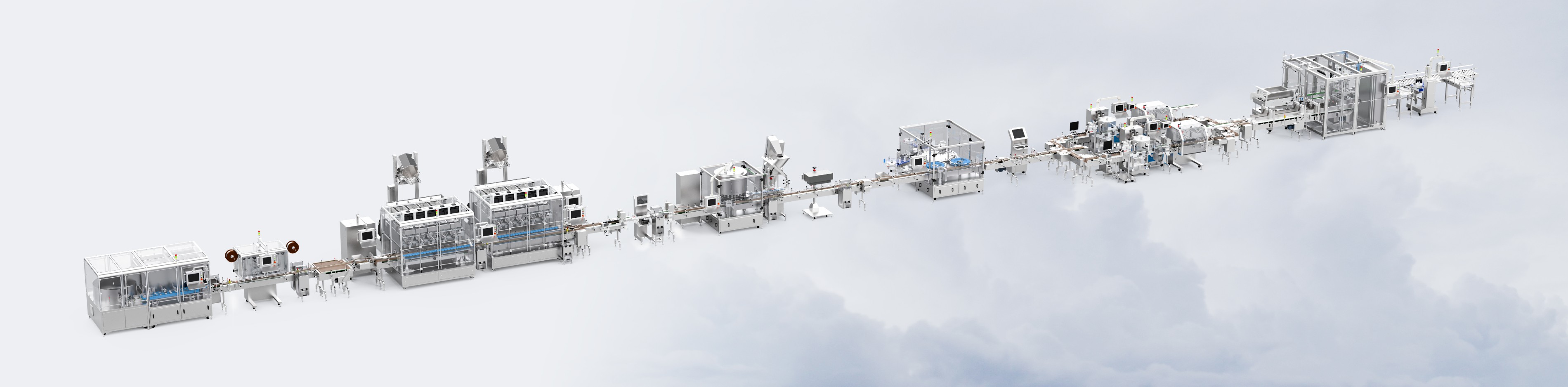

1、 Equipment Introduction

ALFM-08 is a single module laser modular counter,trhe function is automatic counting and filling machine for pills, tablets, soft and hard capsules and other solid granules, widely used in pharmaceutical, health care, food, pesticide, chemical and other industries.

2、 Features

1)Completely modular design

Each unit is designed according to the modular concept, completely independent of the design of a single module, each single module can be replaced or increased or decreased individually; according to the customer's counter line production capacity needs for multi-module combinations; at the same time, reduce the design cost of the counter and shorten the delivery cycle of the order.

2) Continuous Filling System

Compared with the traditional positive cylinder intermittent bottle infeed and loading method, the continuous bottle infeed and loading method is faster and smoother, and completely avoids the problem of impact and bruising to the bottles that may occur in the traditional positive cylinder intermittent bottle infeed and loading method.

(2.1) Continuous screw servo infeed system, screw speed and conveyor belt speed to match completely, to ensure smooth and continuous feeding of bottles.

(2.2) Filling servo system, controlled by servo encoder, synchronized with the total material gate servo system to ensure synchronous and accurate receiving; synchronized with the screw servo feeding system to ensure synchronous and accurate bottle loading.

(2.3) Reject star wheel system, through the servo encoder control, reject star wheel and infeed screw servo system synchronization, through the role of the vacuum system, the need to reject the bottle adsorption to the collection plate, to ensure that the bottle does not fall over, the material will not overflow to produce pollution.

(3) Servo material gate system

(3.1) Servo system control of the total material gate and small material gate, faster, more accurate, longer working life, easier to clean and maintain; and minimize the noise, in full compliance with cGMP requirements.

(3.2) Servo material gate instead of cylinder material gate, cylinder material gate material gate closure time is 50ms, servo material gate material gate closure time is 25ms, the closing speed increased by 50%, the number of particles more accurate and faster;

(3.3) The cylinder of the cylinder material door is usually replaced every 3 months, while the servo motor of the servo material door does not need to be replaced.;

4)Laser counting system

(4.1) the use of new laser detection technology, make full use of the advantages of laser high brightness, high directionality, high monochromaticity, high coherence, to improve the counting process of anti-interference performance;

(4.2) Laser near-parallel directional one-sided light instead of the traditional infrared three-dimensional large scattering angle of light, effectively eliminating the detection of blind zones, the minimum detection of particle size from the current infrared about 2.0mm to enhance the laser about 0.5mm;

(4.3) The visible light of the laser instead of the traditional infrared invisible light, effectively enhance the debugging, testing efficiency.

5) Higher counting speed

Innovative vibration unit for faster counter machine; speed is 50% higher than ordinary counter machine.

6)Can be applied to a wider range of sizes of pharmaceutical grain counting needs

The maximum size range of pharmaceuticals for counting is increased from the traditional Φ13mm to Φ20mm; the minimum size range of pharmaceuticals for counting is reduced from the traditional Φ3mm to Φ1mm; it is better adapted to the market demand.

7) Smaller footprint

One four-module counter machine ALFM-32C is comparable to two ordinary granule counting machines PP-12 in terms of capacity, and its effective floor space is only about 50%.

8) More powerful control system

8.1) Connecting the control system of all equipments in the whole line through Ethernet to complete remote monitoring, management and maintenance; optional remote control system or SCADA system with higher degree of automation;

8.2) Adopting German MCU processor with the highest configuration in the same industry; introducing mature high-speed electronic digital technology from famous foreign manufacturers, based on high-speed microprocessor technology with full Chinese dynamic graphic display of the operating system, the parameters can be set in the setup interface of the touch screen;

(8.3) Automatic fault diagnosis and real-time monitoring and alarm display system, can store 100 groups of product parameters, replacement of the product directly call the stored formula can be;

(8.4) It can increase the three-level password authority function, to fully meet the customer's equipment authority management needs.

9) More abundant optional functions

(9.1) 360 camera detection and rejection function of pharmaceutical material defects;

(9.2) Camera detection and rejection function of drug material fragments;

(9.3) Online static check weigher (reweighing) function;

(9.4) Dust treatment function and vacuum cleaner;

(9.5) Static electricity elimination function;

(9.6) Medicine elevator;

(9.7) Stand-alone SCADA system.