In today’s pharmaceutical industry, improving efficiency while reducing environmental impact has become essential. At Pharmapack, we recognize the importance of sustainable operations and have focused on the low-carbon design of our packaging equipment. Through careful design and technology integration, we aim to provide packaging solutions that align with both operational efficiency and environmental responsibility.

Energy-Efficient Servo and Mechanical System

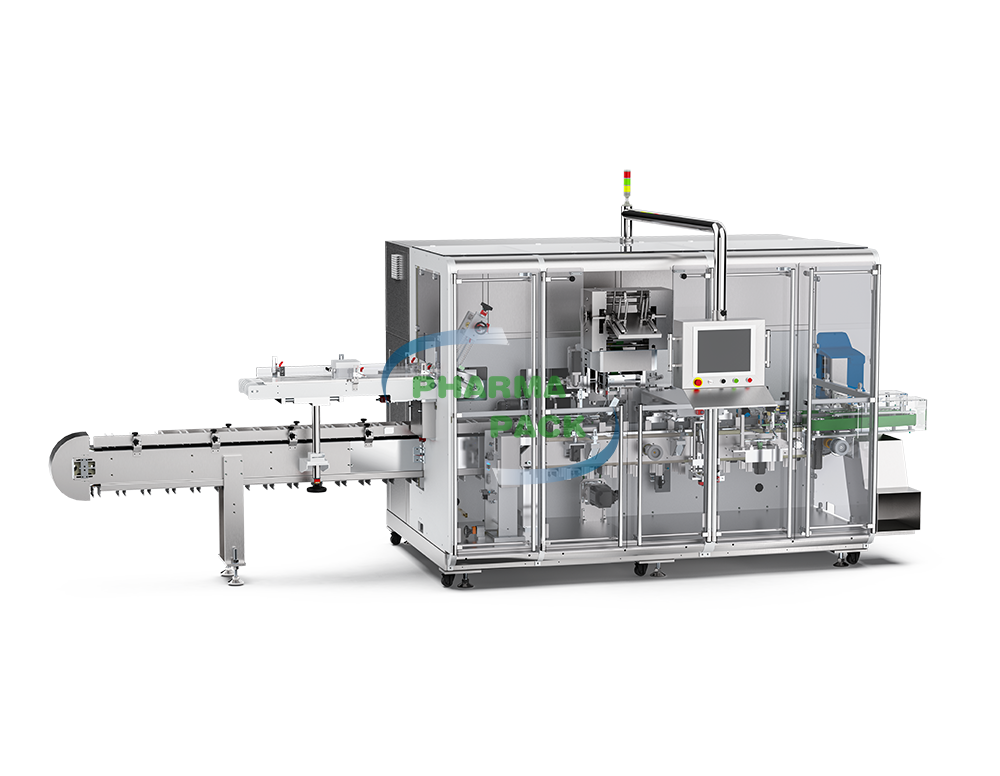

Our LFBI-10 horizontal cartoning machine is equipped with a sophisticated mechanical drive system and industry-leading servo control technology. The new servo design incorporates self-detection features to replace traditional cylinders, significantly lowering energy consumption and maintenance requirements. This approach allows us, as a cartoner machine manufacturer, to deliver machines that use less power while maintaining stable performance, ensuring smoother motion control, minimizing wear on components, and improving long-term reliability. In addition, the technology supports greater flexibility in production lines, helping manufacturers adapt quickly to different packaging formats while maintaining consistent efficiency and environmental awareness.

Optimized Material Handling for Reduced Waste

At Pharmapack, we understand that minimizing waste is critical for a low-carbon strategy. The LFBI-10 features a scratch-resistant white toothed conveyor chain, which ensures smooth carton handling without damage. Products, including fragile items or cartons with lining, can move efficiently through the machine, reducing rejects and minimizing material waste. By designing a machine that handles cartons gently and reliably, we help pharmaceutical companies achieve a measurable reduction in their packaging-related environmental footprint, while also improving operational consistency, supporting greener production practices, and enabling long-term cost savings that align with broader sustainability goals across the industry.

Flexible Integration for Sustainable Operations

Another important aspect of our horizontal cartoning machine is its flexible integration with upstream and downstream processes. The LFBI-10 supports automatic infeed, leaflet insertion, and pre-glued or hot-melt sealing options, allowing a smooth flow in a production line. With PLC controllers and a user-friendly liquid crystal touch interface, operators can easily adjust production parameters to optimize both speed and energy consumption. As a cartoner machine manufacturer, our goal is to provide solutions that allow our customers to scale operations efficiently while maintaining lower per-unit carbon emissions.

Conclusion

We at Pharmapack are committed to supporting pharmaceutical companies in their sustainability efforts. As a trusted cartoner machine manufacturer, we continue to innovate and provide turnkey solutions that balance productivity and environmental responsibility, helping our clients meet their operational and sustainability goals effectively while fostering long-term value, enhancing efficiency across diverse applications, and encouraging greener practices throughout the entire packaging process.