In the pharmaceutical industry, packaging photosensitive drugs presents unique challenges that demand precision, protection, and efficiency. At Pharmapack, we understand how critical it is to maintain the stability and integrity of these sensitive products throughout the packaging process. With our extensive engineering experience and strong R&D capability, we have developed advanced horizontal cartoning solutions designed to meet these demanding requirements. As a trusted cartoning machine manufacturer, we continue to optimize every detail of our equipment to ensure reliable operation and compliance with pharmaceutical standards.

Precision and Protection for Photosensitive Drugs

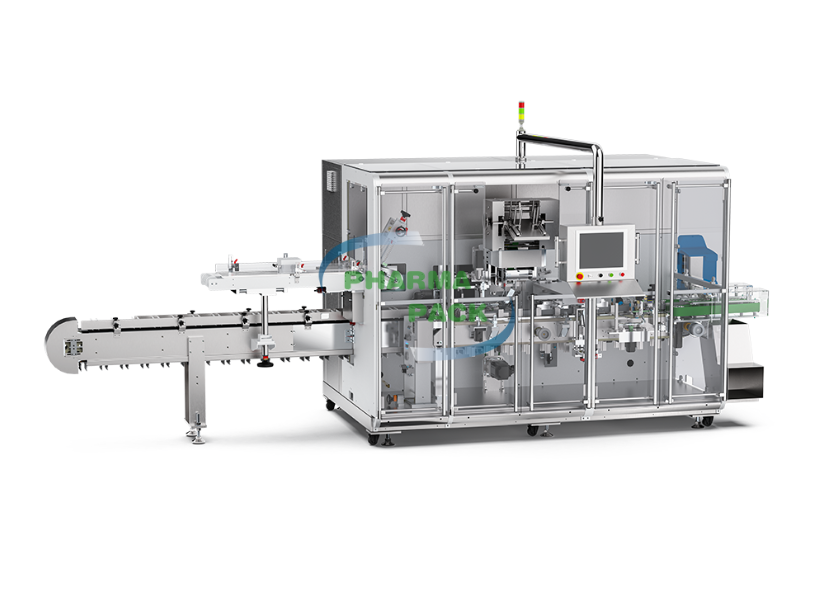

Photosensitive drugs demand packaging that shields them from light while preserving their quality. Our LFBI-10 Intermittent Horizontal Cartoner is specifically designed to meet these needs. It delivers accurate product placement and reliable carton sealing, effectively minimizing the risk of contamination or light exposure. Capable of handling up to 100 cartons per minute (depending on carton size and product dimensions), the LFBI-10 combines speed with precision. Its modular design allows easy adjustment for boxes ranging from 115–200 mm in length and 40–130 mm in width, making it versatile enough to safely package even the most delicate light-sensitive pharmaceuticals under controlled conditions.

Intelligent Design and Advanced Servo Control

At Pharmapack, innovation is at the core of our equipment design. The LFBI-10 horizontal cartoning machine features advanced servo control technology that replaces traditional cylinder systems, reducing dust and vibration during operation. This design not only improves packaging stability but also extends machine lifespan and lowers maintenance costs. Our new servo control system can self-detect abnormalities, ensuring smooth and consistent performance across every production cycle. These features reflect our commitment as a cartoning machine manufacturer to integrate technology that enhances precision, productivity, and long-term reliability.

Meeting the Changing Needs of Pharmaceutical Production

In today’s pharmaceutical manufacturing, packaging equipment must quickly adapt to different product specifications and evolving regulatory requirements. The LFBI-10 is designed to meet these challenges, featuring an intelligent configuration and intuitive control system that accommodate a variety of product and leaflet sizes, ensuring compatibility across diverse drug formulations and labeling needs. With a low power consumption of 17 kW and optimized air usage, it delivers high production efficiency while supporting sustainable operations. Combined with our one-stop service system, Pharmapack provides complete solutions—from smart bottle packaging to secondary packaging—helping clients streamline their entire production process.

Reliable Solutions for Sensitive Pharmaceutical Packaging

Packaging photosensitive drugs requires a perfect balance of protection, precision, and productivity. With decades of experience and world-class engineering expertise, Pharmapack continues to provide pharmaceutical companies with innovative equipment that ensures product integrity and production efficiency. Our horizontal cartoning machine solutions, including the LFBI-10, are designed to adapt to diverse packaging requirements while maintaining compliance and operational stability. As a dedicated cartoning machine manufacturer, we remain committed to delivering advanced, customizable, and dependable solutions that help pharmaceutical producers meet evolving market demands with confidence.