As a professional manufacturer of pharmaceutical packaging solutions, we at Pharmapack understand that every pharmaceutical producer has different packaging requirements. From product protection and aesthetic appearance to production efficiency and material compatibility, the choice of sealing mode plays a crucial role. Our pharmaceutical cartoning machine lineup, including the LFBI-10 Intermittent Horizontal Cartoner, is designed to accommodate diverse production needs with flexible sealing options such as tongue insertion and hot melt glue sealing.

Meeting Flexibility in Modern Pharmaceutical Production

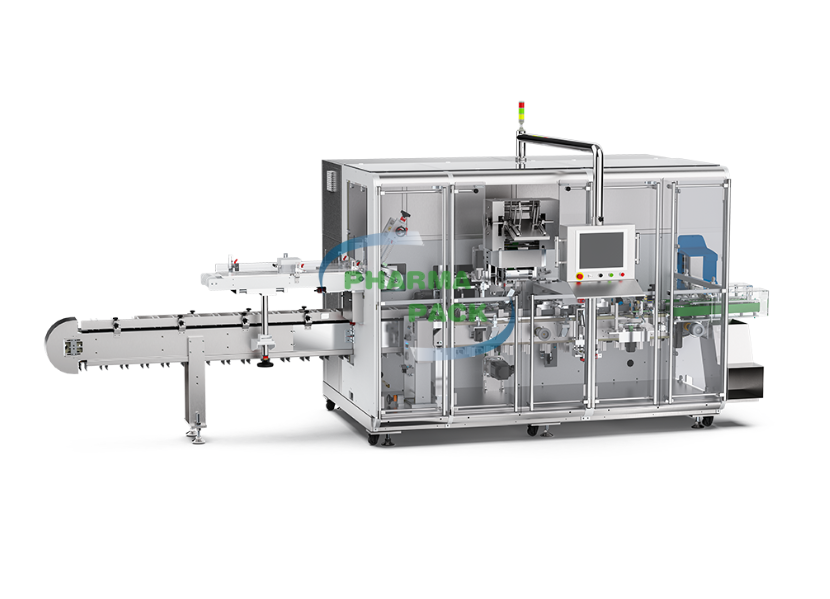

The LFBI-10 Intermittent Horizontal Cartoner is an advanced model capable of handling up to 100 cartons per minute, depending on the product and box size. Its adaptable structure allows for smooth changeovers between tongue insertion and hot melt glue sealing modes. This flexibility enables our clients to tailor packaging operations to specific product types—whether they need a reclosable carton for user convenience or a tamper-evident seal for strict regulatory compliance. By integrating both sealing methods in one horizontal cartoning machine, we provide our partners with a highly versatile, space-saving, and cost-effective solution.

How Different Sealing Modes Fulfill Custom Requirements

Tongue-insertion sealing works best when a neat appearance and easy reclosure are important. By avoiding adhesives, it reduces material waste and simplifies maintenance, making it a smart choice for lightweight or over-the-counter pharmaceutical products that need a secure yet straightforward closure.

In contrast, hot melt glue sealing delivers stronger bonding and excellent protection against moisture and tampering. This makes it ideal for products that must remain tightly sealed until use, ensuring safety and integrity throughout their lifecycle.

Thanks to our engineering expertise and Pharmapack’s advanced servo control technology, switching between these two sealing methods on the same cartoning machine is seamless. The servo system enables precise and stable operation, with built-in self-detection features that minimize dust and extend the machine’s service life, all while keeping production running smoothly.

Built for Efficiency and Reliability

With dimensions of 6400 mm by 2500 mm by 2500 mm and a robust power system (17 kW, AC380–400V), the LFBI-10 Intermittent Horizontal Cartoner offers the performance and durability required in high-demand pharmaceutical environments. The system accommodates a variety of product and leaflet sizes, making it an efficient tool for packaging blister packs, bottles, or tubes. Supported by Pharmapack’s Italian R&D center and Guangzhou production facility, every horizontal cartoning machine is backed by a complete quality control and inspection process to ensure consistent performance and compliance with international standards.

Delivering Smart, Customized Packaging Solutions

At Pharmapack, our goal is to help customers enhance packaging efficiency and reliability through smart automation and modular design. Whether customers choose tongue insertion or hot melt glue sealing, our pharmaceutical cartoning machine solutions offer unmatched adaptability to meet changing market needs. Combined with our one-stop service system—from smart bottle packaging to flexible secondary packaging lines—we ensure each project receives comprehensive support and a fully customized “turn-key” solution.

In conclusion, the combination of multiple sealing modes in the LFBI-10 Intermittent Horizontal Cartoner allows pharmaceutical manufacturers to achieve both operational flexibility and packaging precision. With Pharmapack, you gain not only a reliable machine but also a long-term partner dedicated to optimizing your packaging performance.