For many pharmaceutical manufacturers, the rise of personalized medicine and diversified product lines has made small-batch production a daily reality. Yet this shift raises an urgent question: How can production teams meet strict GMP requirements without letting costs spiral? At Pharmapack, we often see clients struggling with this balance—especially when frequent batch changes and tighter supervision standards increase both operational pressure and expenditure. This is where the horizontal design of an intermittent cartoning machine becomes a practical solution, offering the precision needed for compliance while keeping workflows lean and economical.

Why the LFBI-10 Excels in Small-Batch Scenarios

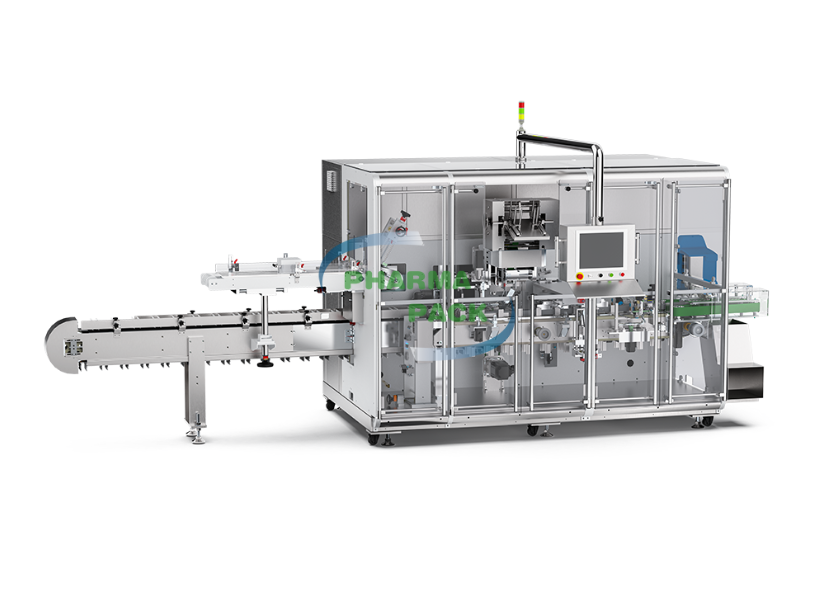

Imagine switching from a vial packaging run in the morning to a blister run in the afternoon—both requiring traceability, hygiene, and consistent carton quality. The LFBI-10 intermittent horizontal cartoner was engineered precisely for this scenario. Its adaptable carton range (115×40×15 mm to 200×130×80 mm) and speed capacity of up to 100 packs per minute allow manufacturers to respond quickly to changing orders without overspending on oversized equipment. The “Balcony” structure ensures every component is visible and accessible, reducing cleaning time between batches. Operators relying on the PLC system and intuitive touch interface can complete product changeovers rapidly and with confidence, ensuring that agility does not lead to errors.

Maintaining GMP Compliance Without Adding Operational Burden

Small-batch production often means more inspections, documentation, and scrutiny. An intermittent cartoning machine must protect fragile cartons, maintain traceability, and support cleanroom requirements while remaining cost-efficient. The LFBI-10 addresses these needs through its scratch-resistant white toothed conveyor chain and optimized mechanical drive system, capable of frequent adjustments without extra wear. Servo-controlled motion enables accurate, repeatable actions while reducing energy consumption. For manufacturers managing rising compliance demands, this combination safeguards product integrity and minimizes waste—two critical pillars for controlling operational costs in small-scale production.

A Scalable Path for Growing Product Lines

As companies diversify into niche formulations or trial-stage products, packaging equipment must evolve from fixed-purpose machines into flexible system components. Pharmapack’s horizontal cartoning machine fits seamlessly into bottle, inspection, flexible, and secondary packaging lines, forming a one-stop solution. Modular design gives manufacturers the freedom to adjust capacity or product variety without major reinvestment. Whether expanding a pilot run or stabilizing small-batch commercial production, our engineering ensures each machine remains reliable, hygienic, and aligned with regulatory expectations—while keeping long-term operating costs manageable.

Balancing compliance and economy in small-batch pharmaceutical production doesn’t have to be a trade-off. The horizontal design of Pharmapack’s LFBI-10 intermittent cartoning machine shows how precise control, modular engineering, and user-centered operation can support both regulatory confidence and operational efficiency. By enabling fast changeovers, stable performance, and hygienic design, the LFBI-10 helps manufacturers handle diverse product requirements while maintaining cost-effective packaging workflows. In an industry where flexibility is as crucial as accuracy, our solutions enable businesses to stay compliant, efficient, and competitive.