Ensuring reliability in pharmaceutical supply chains has never been more critical. At Pharmapack, we understand that medical companies and pharmaceutical manufacturers require advanced automation solutions to maintain production efficiency and comply with strict quality standards. Our horizontal cartoning machine and intermittent cartoner lines are designed to meet these challenges, providing ISO 13485-certified intelligent packaging robots that streamline operations while enhancing safety and consistency. By integrating sophisticated technology and robust engineering, we help our clients maintain uninterrupted production and minimize risks in the supply chain.

Innovative Design for Efficient Cartoning

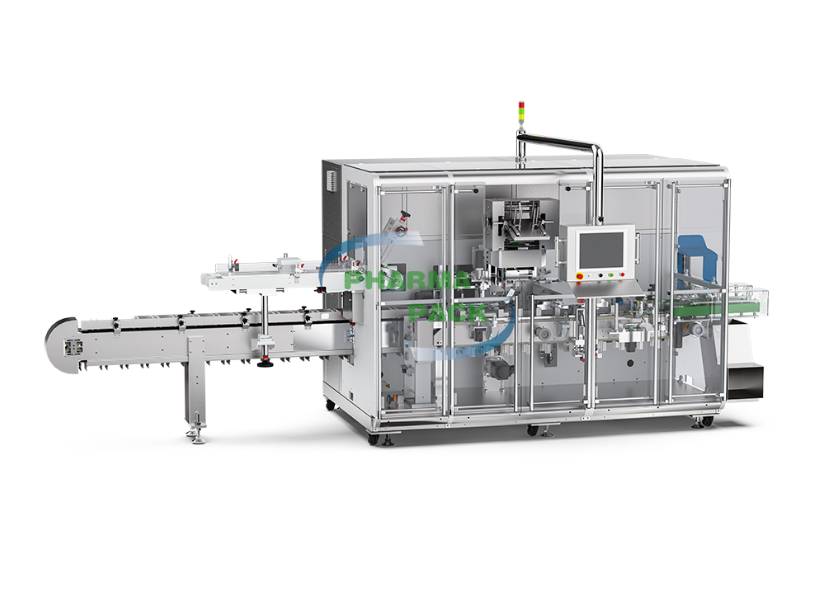

The LFBI-10 Intermittent Horizontal Cartoner reflects our focus on smart, practical packaging solutions. Built for the automatic cartoning of medicines and cosmetics, it can handle up to 100 packs per minute, depending on carton and product size. Its distinctive “Balcony” design places the main and auxiliary drives alongside the conveyor, making maintenance, inspection, and product changeover easier while keeping dust and debris away from critical components. At Pharmapack, we prioritize reliability in every detail: the scratch-resistant conveyor ensures delicate products move smoothly, maintaining both carton integrity and product quality from start to finish.

Advanced Technology Supporting Supply Chain Reliability

Our ISO 13485-certified solutions integrate precise servo control and modular design concepts that adapt to various production needs. By upgrading traditional cylinders to self-detecting servo systems, we reduce maintenance costs and improve operational stability. Both our horizontal cartoning machine and intermittent cartoner feature PLC controllers with liquid crystal touch interfaces, offering user-friendly operation and rapid product changeovers. These intelligent systems guarantee consistent packaging quality, which is essential for medical manufacturers seeking reliable supply chain performance. At Pharmapack, we combine decades of engineering expertise with global R&D insights to ensure that every packaging line meets rigorous safety and efficiency standards.

One-stop Service and Full Support

At Pharmapack, we go beyond supplying machinery—we deliver complete, tailored solutions. Whether it’s a Smart Bottle Packaging Line or a Smart Secondary Packaging Line, every system we provide is designed to meet the specific needs of our clients. Each horizontal cartoning machine and intermittent cartoner comes with robust support from our quality control and service network. Our technical experts ensure that installations and operational adjustments comply with GMP standards and local safety regulations. With over 70 senior engineers at our Innocentre headquarters and a European R&D branch, we offer seamless, end-to-end support that strengthens reliability throughout the pharmaceutical supply chain.

Efficiency and safety are critical in pharmaceutical packaging, and Pharmapack’s ISO 13485-certified intelligent packaging robots are designed to deliver both. By integrating our horizontal cartoning machines and intermittent cartoners, companies can boost productivity, minimize downtime, and maintain supply chain integrity. Our solutions combine advanced automation, practical design, and attentive service, showing how technology and experience come together to make packaging smarter and more reliable. Choosing Pharmapack means partnering with a team that brings engineering expertise, innovation, and comprehensive support to keep your operations running smoothly.