At Pharmapack, we constantly focus on providing innovative solutions for pharmaceutical packaging. One of the most valuable features in modern production lines is the automatic production report generation function in horizontal cartoning machine systems. This function allows our clients to monitor packaging data on a daily, weekly, or monthly basis, and export analysis reports that support informed decision-making. By integrating this function into a cartonator packing machine, production managers can gain real-time insights into operational efficiency and identify areas for improvement without manual calculations.

Improved Production Monitoring with Automated Reports

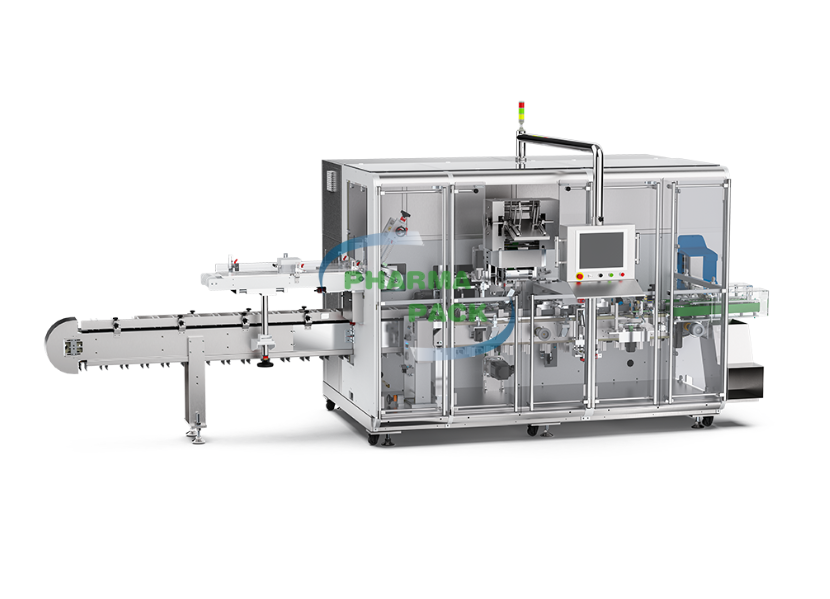

Our LFBI-10 Intermittent Horizontal Cartoner is designed with an automatic reporting system that tracks essential production metrics such as cartons processed, rejected units, and machine uptime. The horizontal cartoning machine ensures that data is recorded continuously and accurately, providing operators with up-to-date information. This function not only improves traceability but also helps pharmaceutical companies comply with internal quality standards. By exporting reports in convenient formats, clients can conduct detailed analyses to optimize their packaging workflow and enhance overall productivity.

Simplifying Workflow with Pharmapack Technology

The Pharmapack Cartonator packing machine blends sophisticated mechanical design with an intuitive PLC controller and a clear liquid crystal touch interface. This combination makes scheduling production straightforward and lets the system automatically generate packaging reports on a daily, weekly, or monthly basis. The LFBI-10 model, designed for both medicines and cosmetics, accommodates a wide variety of carton and product sizes, offering true operational flexibility. By automating reporting, the machine reduces manual work and human error, freeing managers to concentrate on improving overall processes instead of spending time on data entry.

Optimized Data for Strategic Decision-Making

With a horizontal cartoning machine equipped with automatic reporting, managers can quickly identify trends, detect bottlenecks, and plan maintenance schedules effectively. Pharmapack's expertise ensures that the data generated by our cartonator packing machine is accurate, reliable, and ready for analysis. This feature is particularly beneficial for pharmaceutical companies that require precise monitoring of production output to meet regulatory standards and maintain high efficiency across multiple packaging lines.

Integrating the automatic production reporting function into Pharmapack cartoning machines helps clients simplify their operations and make more informed decisions. Our horizontal cartoning machines and cartonator packing solutions provide reliable monitoring, versatile operation, and easy report export options. With these capabilities, pharmaceutical manufacturers can boost packaging efficiency while ensuring full compliance with quality standards.