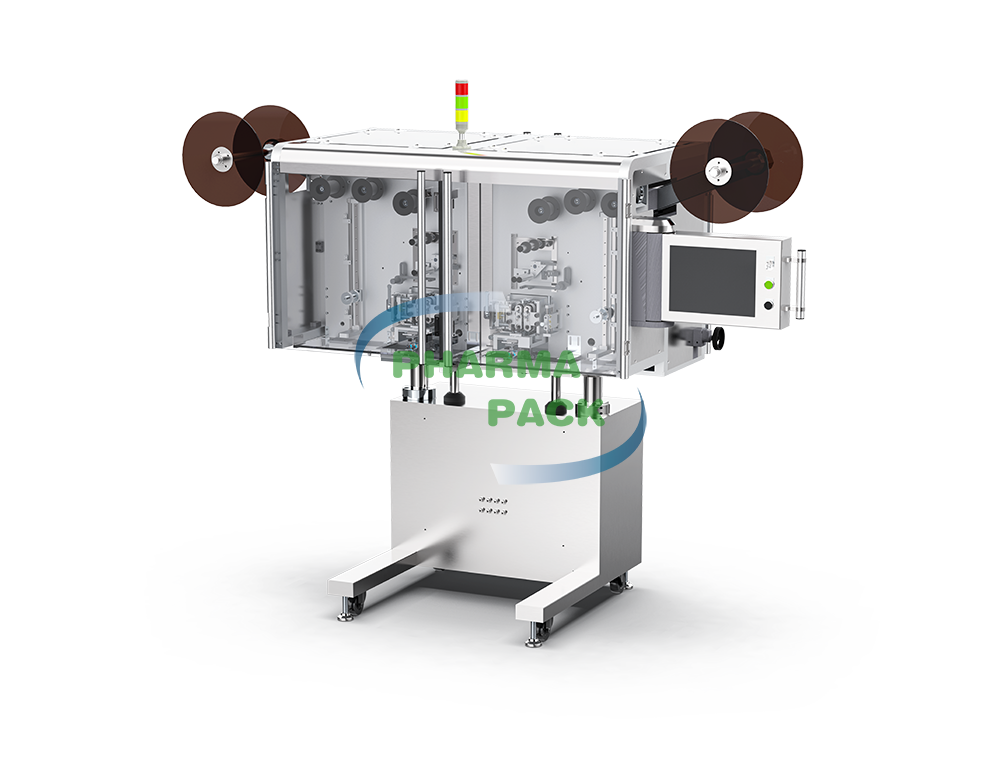

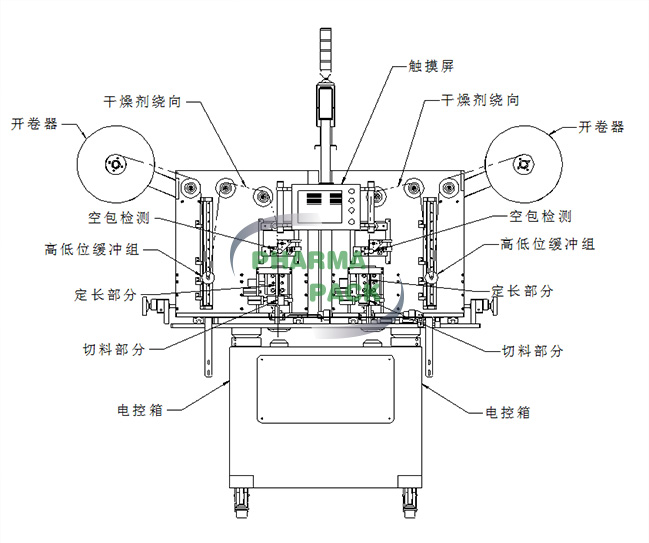

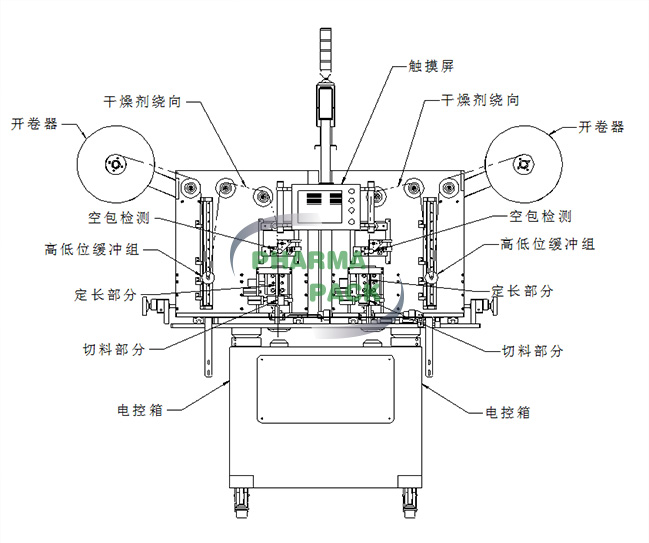

WORKING PRINCIPLE

According to the size of the desiccant, the corresponding parameters are set on the touch screen to control the clamping feeding device. When clamping feeding belt drives the sachets to feed, the uncoiling device uncoils the desiccant roll for feeding. The fixed length conveying part sends the desiccant to the I- mark detection station, where the I-mark sensor detects the sachet and send the signal to PLC. During this process, if U-shape switch did not detect and find it as empty sachet, and the sachet is just right there at the preset cutting station, the cutting knife acts to cut off the sachet dessicant,which fall into the outfeed nozzle( the small gate is in closed state now),Camera detection system works to detect whether there is broken sachet or not through the transparent glass on the outfeed nozzle.If no broken sachet desiccant is found,the small gate will be open,sachet desiccant will automatically fall into bottle to complete the feeding operation.

FEATURES

1.Compact structure, beautiful appearance and easy maintenance.

2.Adopt original imported double servo motor for feeding, accurate positioning.

3.Uncoil the sachet desiccant roll by using motor automatically so that the tension of the desiccant is stable, and there is no material stuck or broken.

4.The I-mark sensor is used for positioning, which can automatically identify the length of the desiccant, and the positioning is accurate.

5.The cutter is driven by SMC double cylinder with adjustable angle, sensitive cutting and multiple protection to ensure that each sachet desiccant can be cut off.

6.Use U-shape sensor and I-mark sensor to prevent empty sachet and broken sachet.

7.Input sachet desiccant length through touch screen operation interface, and positioning is accurate.

8.PLC control, Chinese interface touch screen, easy to learn, easy to operate.

9.Adjustable bracket for bottle of different height.

10.Suitable for paper - paper, paper - plastic packaging materials with back-sealed and integrated roll of sachet desiccant.

11.The machine is made of stainless steel and other materials in accordance with GMP requirements.

12.It has the function of preventing the bag desiccant from solidifying and can be used by single machine or multiple machines.