당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

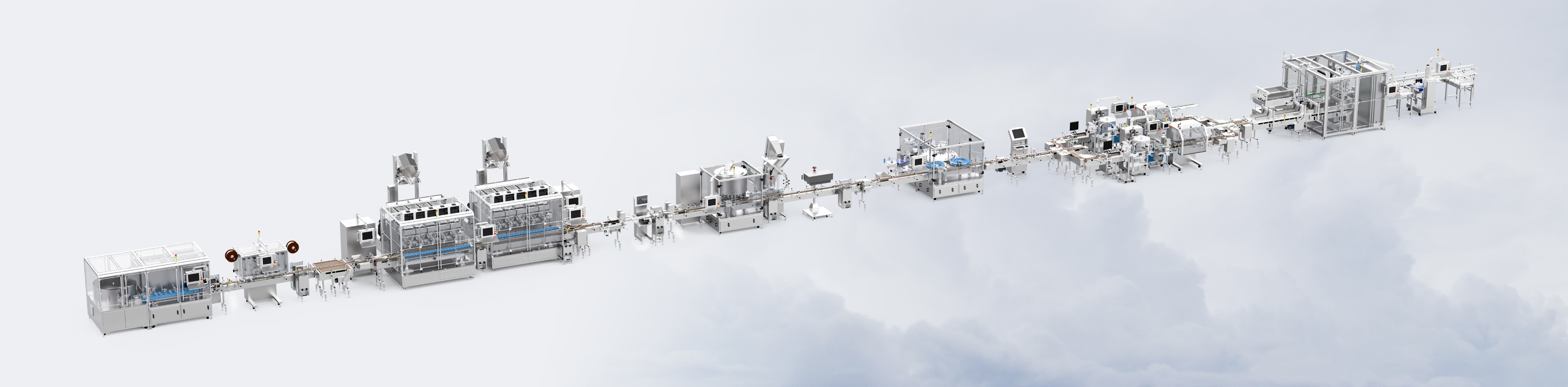

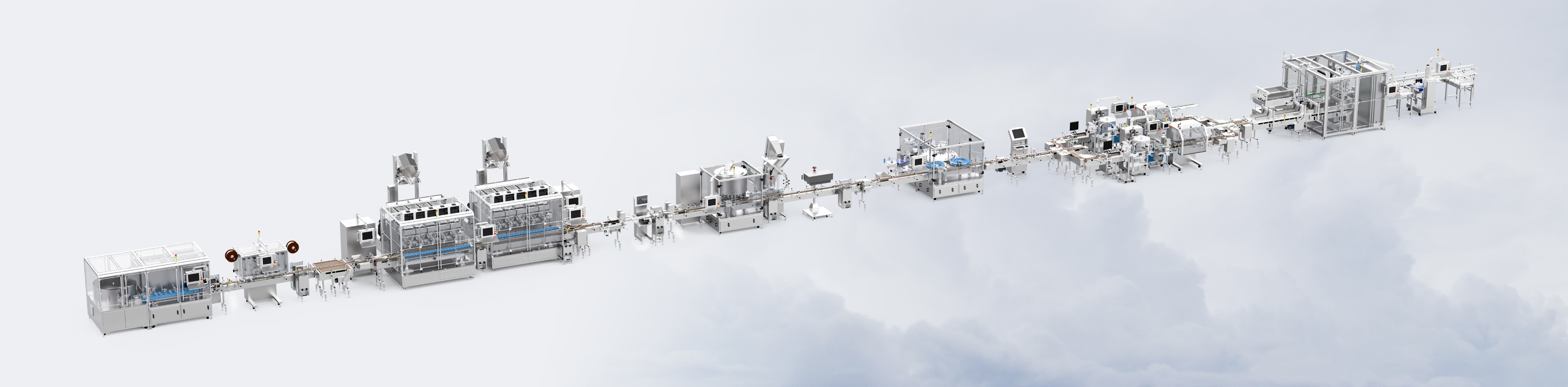

Model | LFID-06 |

Max. output | 60 sachets/min |

Sachet size | Length: 20~50mm Width: 10~30mm |

Bottle size | Round Bottle: φ20~φ100mm; Square Bottle: 20~100mm |

Height: 40~200mm | |

Power supply | AC220V 50/60HZ |

Wattage | 0.55 KW |

Air pressure | 0.5~0.7 Mpa |

Air consumption | 10L/min, clean air |

Measurement(L×W ×H) | Approx. 860mm×600mm×1600mm |

Weight | Approx. 80kg |

WORKING PRINCIPLE

The desiccants strip on the roll holder is routed through several guiding wheels, through the length verification device and into the dispenser. Once the machine starts, the dispenser feeds a preset length of the desiccant strip with the help of the servo motor. If the actual length is confirmed as the setting by the length verification device the desiccant sachet will be cut by the cutter and drop into the bottle via the nozzle.

PERFORMANCE

The LFID-06 is a reliable, high performance machine, designed in conformance with current and proposed GMPs. Having a small footprint, it is effective in maintaining the integrity of a clean room environment. Few changeover parts are required (only a nozzle for different bottle openings).