당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

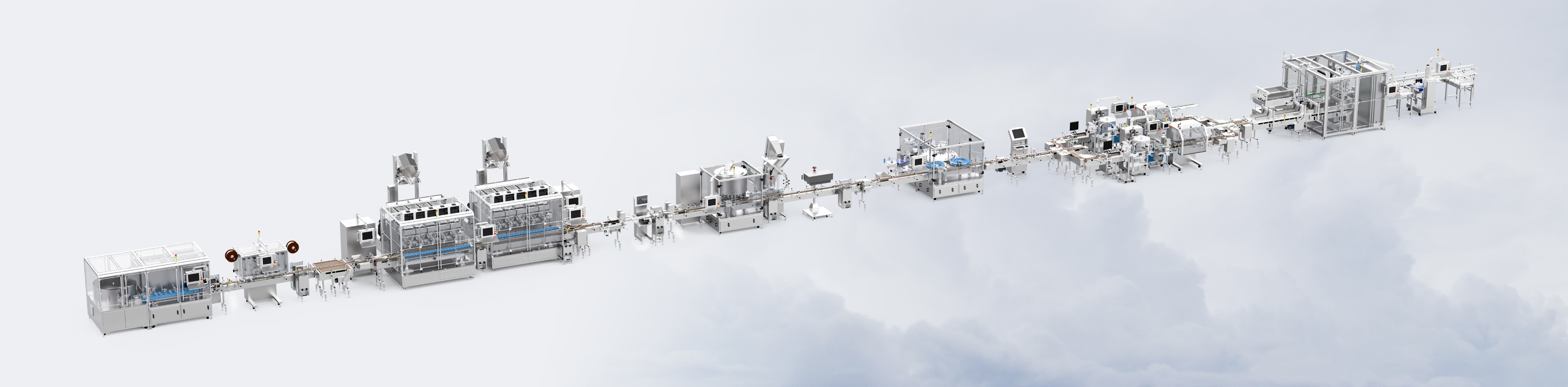

Model | LFIS-20/30 |

Max.speed | 200/300 BPM |

Bottle diameter | φ30~φ100mm |

Bottle height | 40~200mm |

Desiccant diameter | 14-25mm |

Air pressure | 0.4-0.7MPa |

Air consumption | 15L/min |

Power supply | AC220V/50Hz(60Hz) 500W |

Dimensions | 828mm(L)×1965mm(W)×2055mm(H) |

Weight | Approx.200kg |

FUNCTION

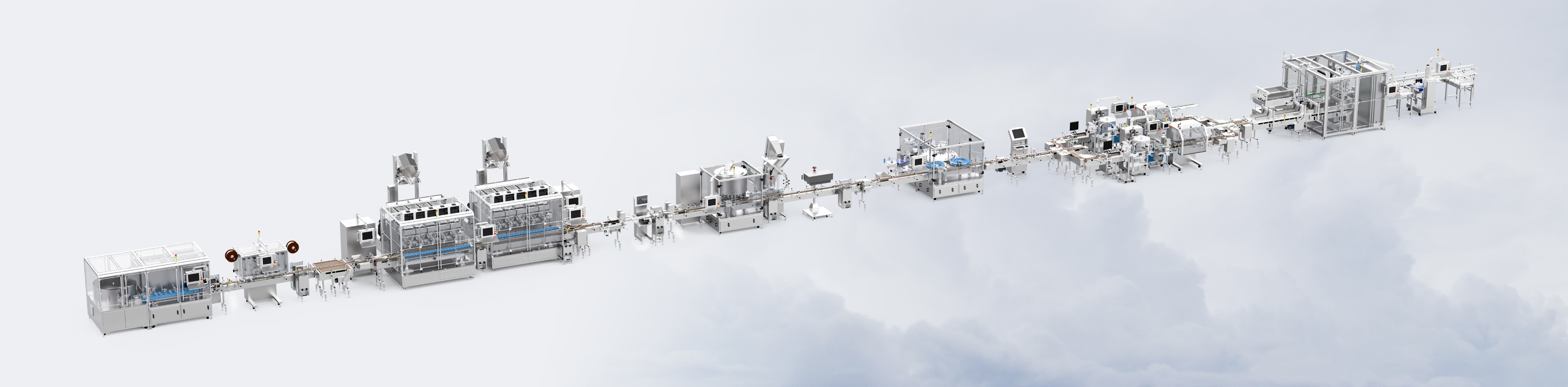

LFIS-20/30 canister desiccant inserter is a special equipment for tablets, pills, capsules and other solid pharmaceuticals in bottles, boxes or bags into granular solid desiccant. It is used in the pharmaceutical, healthcare, food and other industry . It meets GMP standards. It has beautiful appearance, compact structure and convenient maintenance. It adopts servo drive, PLC control system and man-machine interface. It is reliable in operation and easy to operate.

This machine can be used as a stand-alone, can also be provided with the company's automatic unscramble , automatic counter, capper, induction modular counter sealing detection system and labeler supporting the use of a more complete bottle packaging line, but also with other types of packaging line matching.

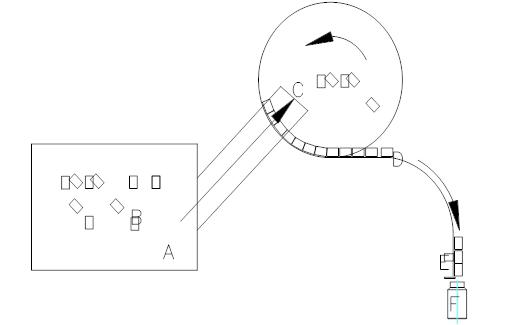

WORKING PROCESS

As shown in figure, manual product B into the hopper of the hoist A, hoist the material B automatically into the turntable C, through the turntable to the material ordered to the channel D, at the end of D has the escapement mechanism E, can one one of the material down, automatically fall into the bottle F.When the bottom of the conveyor belt has a bottle of electric eyes detected that there is a bottle, E action once, the material automatically fell into the bottle.When the bottle positioning time to meet the parameters set by the PLC programming, the pneumatic system automatically changed bottles.Can realize fully automatic operation;Can be more than one per bottle.