당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

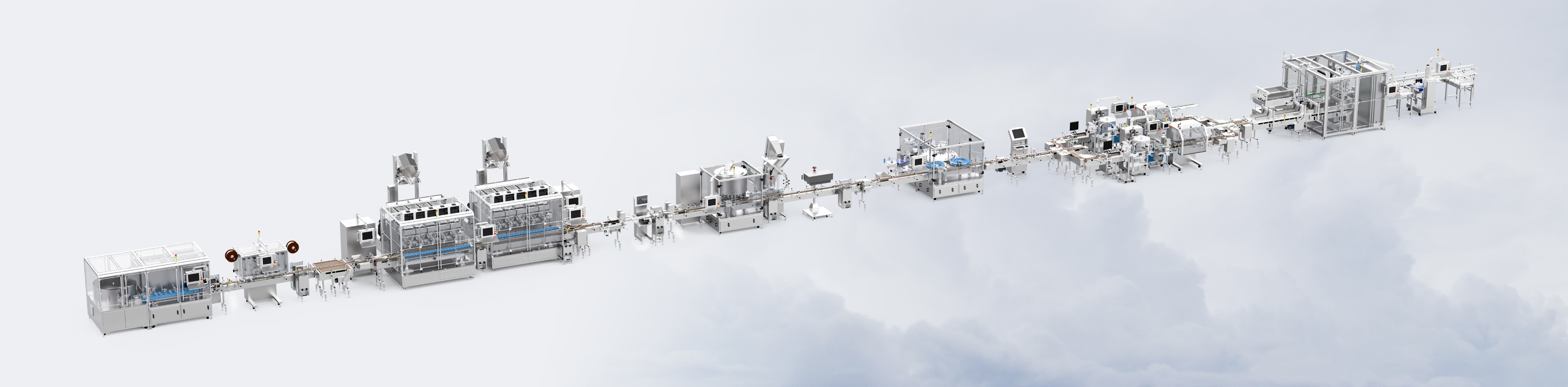

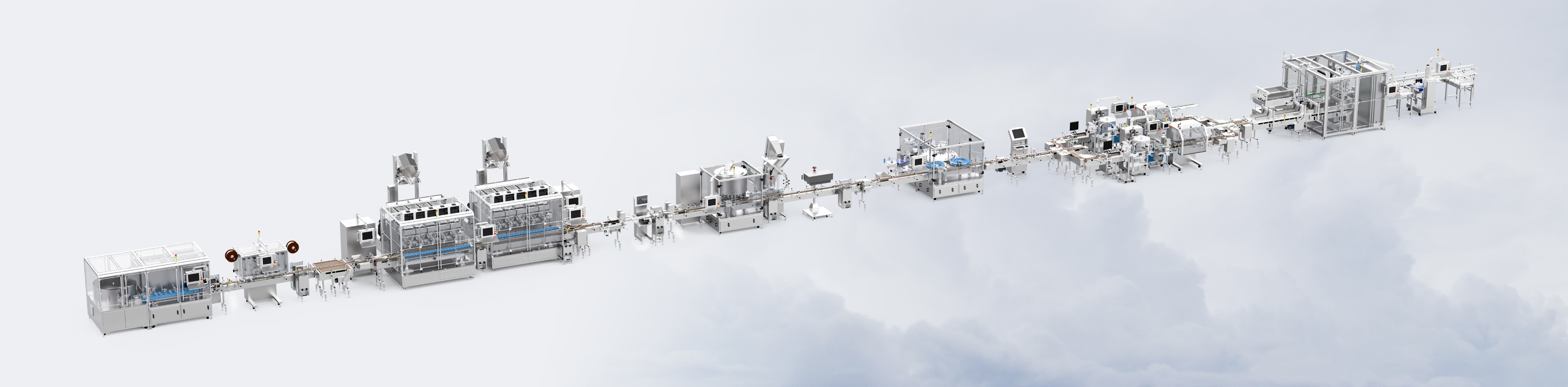

Model | LFIS-12 |

Max. output | 120 pieces/min |

Canister Desiccant size | Length: 15~50mm Diameter: 8~30mm |

Power supply | AC220V 50HZ |

Wattage | 0.5 KW |

Air pressure | 0.5~0.7 Mpa |

Air consumption | 20L/min, clean air |

Measurement(L×W ×H) | Approx. 900mm×600mm×1700mm |

Weight | Approx. 200kg |

WORKING PRINCIPLE

Canister desiccants are manually loaded into the hopper with elevator and then the elevator transfers them onto a turntable. Via the turntable, the canister desiccant transfers into the tunnel and is held by a grasping device. When a bottle arrives, the grasping device releases a desiccant into the bottle. When bottle orientation time reaches the preset value in the PLC, the pneumatic system automatically changes bottles. This equipment can be fully automatic and is applicable to insertion with more than one desiccant.

PERFORMANCE

The LFIS-12 is a reliable, high performance machine, designed in conformance with current and proposed GMPs. PLC control with Touch Screen Panel allows easy operation, insertion speed up to 120 bottles / min. for high speed applications inthe pharmaceutical industry. The machine is of hygienic design that meets GMP standards. It is easy to operate and adjust. Minimal maintenance and fast size changeover helps to increase productivity