당사와 선정된 제3자는 기술적인 목적으로, 그리고 귀하의 동의 하에 쿠키 정책에 명시된 다른 목적으로 쿠키.

또는 유사한 기술을 사용합니다.귀하는 본 고지문을 닫거나, 본 고지문 외부의 링크나 버튼을 사용하거나, 다른 방식으로 계속 탐색함으로써 해당 기술의 사용에 동의할 수 있습니다.

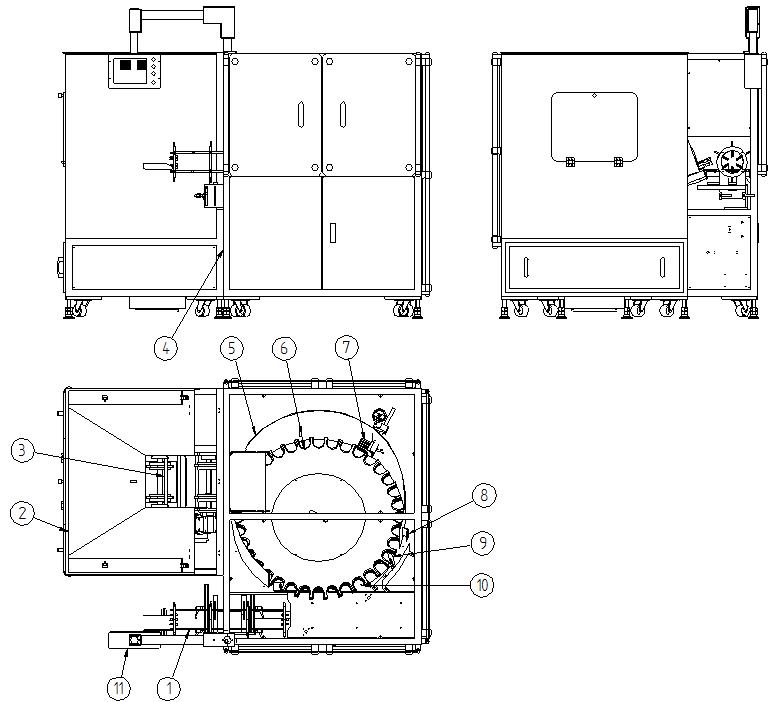

Model | LFU-15FC |

Max.speed | 150BPM |

Bottle Diameter | φ30~φ100 mm |

Bottle Hight | 50~200 mm |

Compressed air pressure | 4 -7bar |

Compressed air consumption | 200 L/min |

Power supply | AC220V/50Hz(60Hz) 1.6KW |

Physical dimension | Approx.2160 (L)×1616(W)×1820 (H) mm |

Weight | Approx.520kg |

Manual or automatic product A into the hopper 02, and through the lifting mechanism 03 will feed the material into the bottle 05, in the main star wheel 06, sweep bottle mechanism 07, blow bottle Nozzle 08 Air Flow Joint action, to remove the star wheel mold cavity outside the surplus material;Then in the Anti-Bottle correction mechanism 09, anti-bottle rejection nozzle 10 under the action, the Anti-Bottle (the mouth of the mouth), the orderly export of the bottle face up.The operation control and parameter adjustment of the device can be operated on the touch screen 11.Electrostatic elimination Device 01 for the optional parts; electrostatic elimination device 01 channel size and the main star wheel 06 according to the condition of the material adjustment or replacement, the operation method of reference to the following "equipment composition and introduction" in the corresponding section.