Tens of thousands of tablets, pills, and capsules were packaged on the machine. Filling, counting, this series of actions are achieved through specialized packaging machines. So how is the dose of each pill or capsule achieved?

Can their numbers be calculated accurately? Yes, it can. Relying on the fully automatic modular Counter, such as the capsule counter machine. We can automatically calculate any product dose and quantity in a high-speed operation mode with nearly 100% accuracy.

For more than a decade, people have been looking for better pharmaceutical packaging equipment, looking for a reliable pharmaceutical packaging machine manufacturer. We are one such pharma packaging machinery manufacturer.

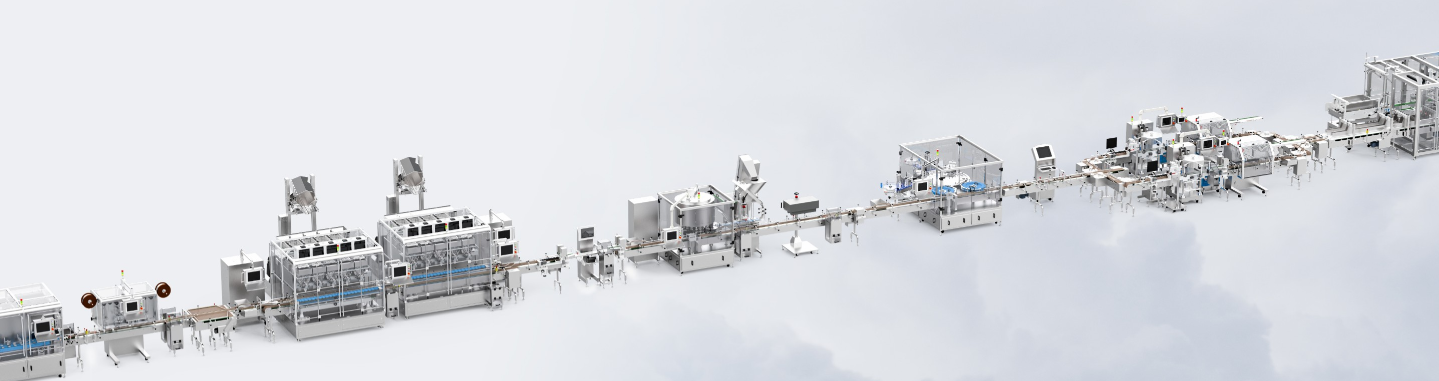

Pharmapack focuses on providing cost-effective equipment and integration for the pharmaceutical, food, and healthcare industries, aiming to become a packaging leader in the packaging machine industry. It’s Pharmapack, who will come to provide you with professional pharmaceutical packaging solutions.

Why Choose Our Solution

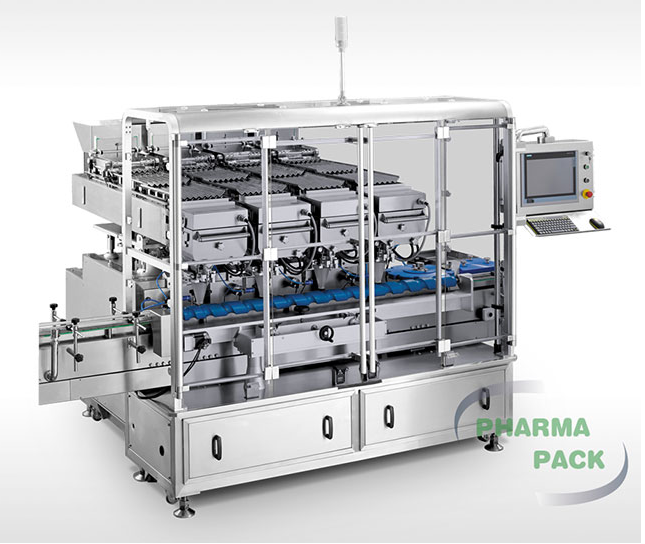

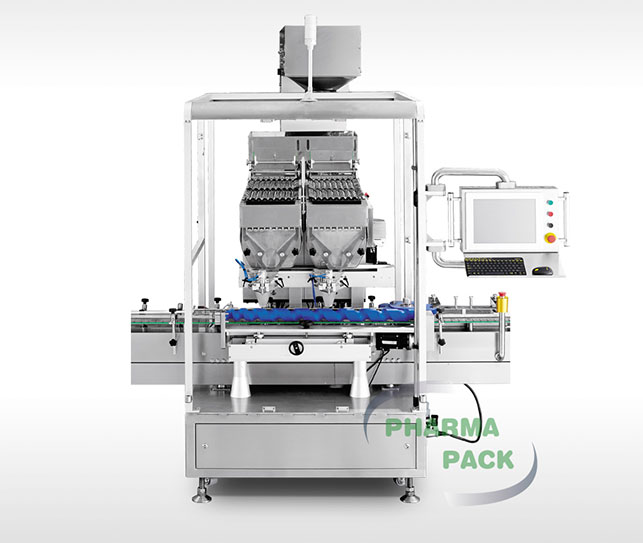

Pharmapack Counter

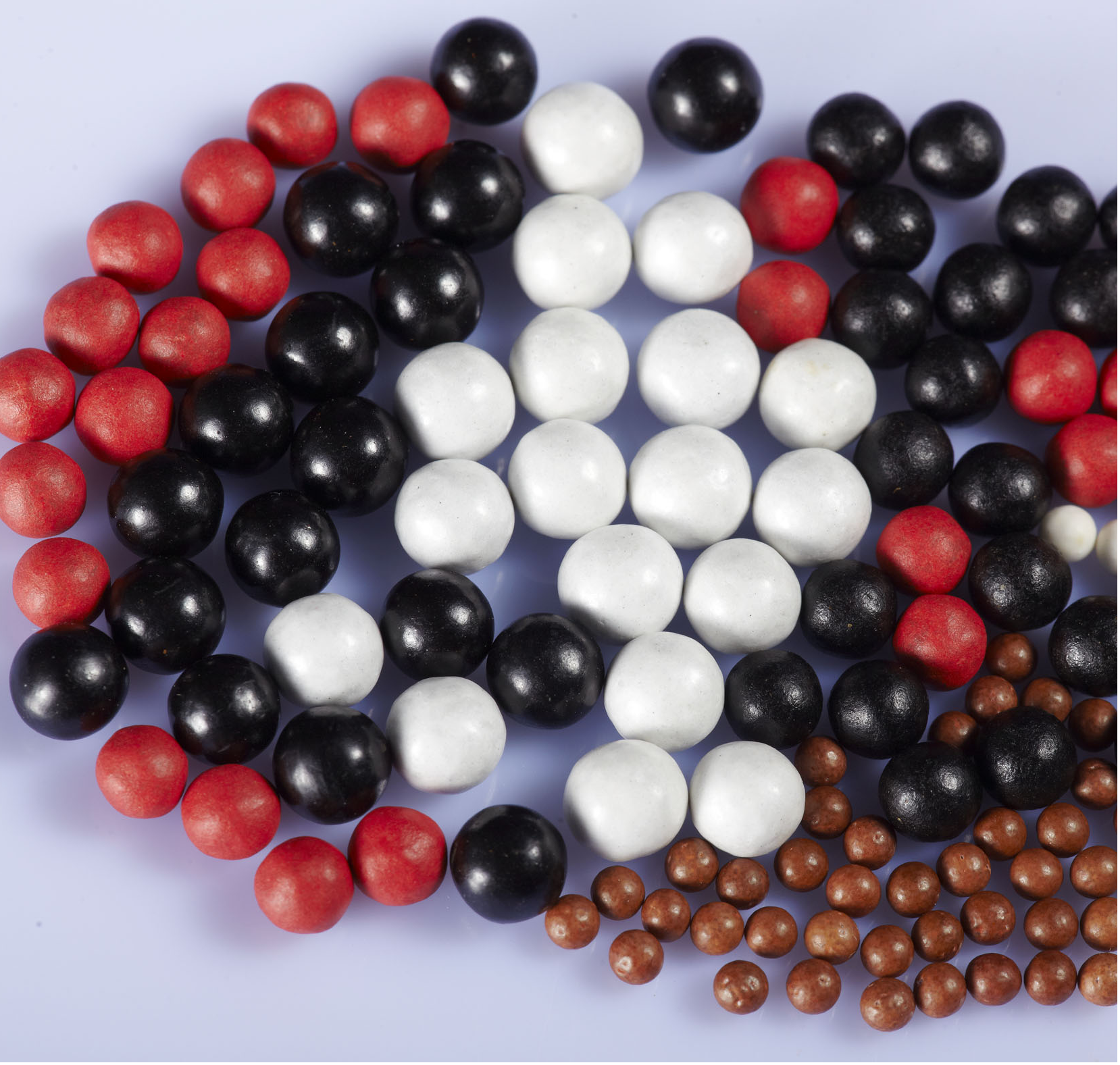

PP Counter series, which exists specifically for the production needs here. There are a total of more than a dozen Counter s, all of which are special machines designed in the pharmaceutical, healthcare, and food industries. The PP Counter series is an electronic channel counter, designed specifically for the high-speed, high-precision counting of tablets, capsules, and soft gels. The machine is standard with an automatic dust compensation system, dual vacuum port, product count verification, and removal. They have all standard features with options including hopper level control with tower lights, inverted bottle sensors, electrostatic elimination rods, channel blockers, and ground-based tablet prefeed.

Pre-sale and After-sale Service

Pharmapack can supply the most perfect "turn-key" packaging solutions for every customer. Tested by internationally certified companies, our equipment has passed the evaluation of CE, UL Certify, CSA and complies with GAMP, FDA (CFR21), cGMP, and TGA standards. Pharmapack provides you with pre-sale consulting services, factory acceptance testing, integration and installation, training, follow-ups, 24/7 internet support, and on-site services.

Advantages of PP Counter Series

In operation, our machine is easy to operate and the parameters settings are simple.

· In terms of performance, the counts are accurate and fast.

· As for design, the machine does not require expensive parts and requires no frequent replacement of parts.

· As for mobile, the machine covers a small area, is convenient to move, is conducive to keeping clean and tidy.

Best Feature of Our Counter

We use the Pharmapack PP- Modular Series Continuous Motion counting and the filling system, which is developed by ourselves. It can easily be integrated into a bottle packaging line with small footprints and few change parts. The changeover is toolless, simple, and quick. With No Hidden traps for tablets, the cleaning is clean quick, and simple. Fully modular design, total modules are designed as unique and have separated parts.

Our electronic automatic counters are more accurate than other automatic tablet counter machines, as our PP-Modular Series Continuous Motion counting and the filling system specifically designed sensors to achieve fast, high-precision tablet counting. Our proprietary sensor technology uses specially modified, custom-designed sensors that allow the operator to control thresholds and single latencies. This counting technology has a fault self-diagnosis and real-time monitoring alarm display system that can adjust the operation latency to prevent the possibility of repeated counting.

Hot Sale Counter For You

Follow-up Filling Modular Counting Machine PP-12MC:

PP-12MC was designed to be our most versatile pharma filling machine. Products of any kind can be counted including clear soft gels and veterinary products. Its tablet size is Φ3-Φ20mm; Applicable to tablets, capsules, caplets, soft gels, transparent soft capsules, etc.

Maximum Production Speed:12000 pcs (depending on the size of the product being inspected)

Automatic Modular Counter PP-24M:

It uses the Pharmapack PP- Modular Series Continuous Motion counting, with the efficiency of filling up to 400 bottles per minute. Its tablet size is Φ3-Φ20mm; Applicable to tablets, capsules, caplets, soft gels, transparent soft capsules, etc.

Maximum Production Speed:24000pcs (depending on the size of the product being inspected)

Tablet Counting Machine for Pharmacy PP-16:

And PP-16 is also a reliable, high-performance automatic counting machine. Few change parts are needed for different container sizes. The product size it fits is 3~10mm thickness, 3~13mm Dia, and 3~21mm Length.

Maximum Production Speed:16000pcs/min (depending on the size of the product being inspected)

Tablet Counting&Check Counting Application

Pharmapack's automatic Counter machine works for the pharmaceutical, healthcare, and food industries, available for packaging applications in tablets, pills, capsules. You can choose the matching machine and equipment based on the size and dosage of the product needed to package.

Most of the nutraceutical, pharmaceutical, food, and other companies that rely on our automated PP tablet counter use it as an automatic production filler to boost production speed and efficiency. Our exclusive packaging technology---New servo control with self-detection to replace the old cylinder, the flapper free of dust effect, more stable, longer life-span, lower maintenance cost. It can better meet different customer requirements.