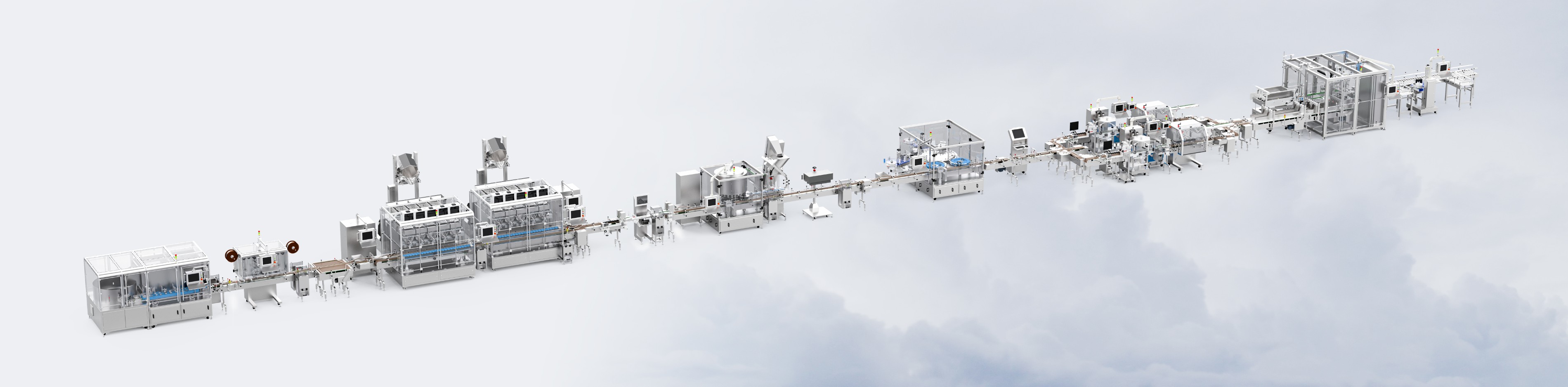

Function:

LFU-40C is an automatic bottle unscrambling machine designed specifically for the pharmaceutical, healthcare and food industries.

The function of LFU-40C is that products arbitrarily placed through specialized agencies are rearranged, at a certain speed, to the next process.

Application:

Suitable for use on cylindrical, oval and rectangular plastic bottles with a height between 45~150mm and outer diameters of 20~105mm, too large, too small and not impact-resistant Bottles (such as glass bottles) are not suitable for this machine. In practical applications, PU-40C is usually used with other machines, such as automatic counting machines and other fill counting devices.

Main Features:

l High speed up to 400 bottles per minute

l Equipped with SCADA system

l Broken tablet detection and rejection system

l Track & Trace System

l Comply with GMP and FDA requirements

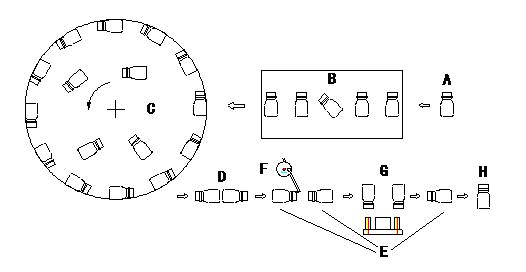

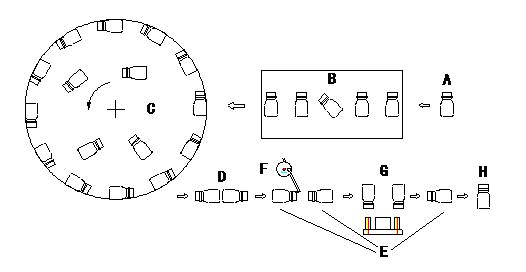

Working principle :

l A a B: Manual or automatic product A in hopper B

l B a C: Through the lifting mechanism in the C gun

l C a D: According to the product specifications, the turntable at a specific rotation speed, the product along the barrel wall in the bottle body D

l D a E: and then the bottle conveyor of the manager in the mechanism of the bottle of reason E

l E a F: in the F to straighten the direction of the mouth, and then the manager of the bottle conveyor belt and export to the next process (product conveyor belt)

Solution

We know that every business is different. That's why we offer a variety of custom packaging equipment that meets the unique needs of our customers.

Application in industry

Model: LFU-40C

Function: Products arbitrarily placed through specialized agencies are reorganized.

Industry: Pharmaceutical, Healthcare, Food

How the Pharmapack Bottle Unscrambler Can Help Your Production

The Pharmapack bottle unscrambler is ideal for keeping up with your packaging demands. Our bottle orientation machines are designed for long-lasting, consistent operation and are suitable for your specific bottle size and speed range. Bottle unscramblers are safe to operate, easy to use, and built to keep your operation running efficiently and smoothly.

Personalized Services

Pharmapack offers turnkey packaging solutions tailored to its customers. Pharmapack offers individual solutions based on the data and needs provided by different customers.

l Professional pre-sales and after-sales service center in Asia, Europe and North America.

l Solutions for design, commissioning, maintenance or upgrade aspects.

l Group dedicated to 24-hour online customer service

Cases

At present, Pharmapack machines have been exported to more than 30 countries and regions around the world. We have successfully provided line installations for many well-known companies.

International:

Such as Pfizer, GSK, Johnson & Johnson, Abbott, Sanofi, AstraZeneca, Baxter, Mars, Wrigley, Perfetti, L'Oreal, AVON

Maidservant:

TongRenTang, Salubris, Jilin AoDong, North China Pharmaceutical Company, Harbin Pharmaceutical Group Holding Co., Ltd.

Yunnan Baiyao Group Co., Ltd, Guangzhou Pharmaceuticals. The Yangtze River, Tasly Pharma, Infinitus, BY HEALTH, etc.

Why choose the Pharmapack machine?

Experienced R&D Group PharmaPack brings together advanced technology in the world to provide the most advanced and guaranteed technical support for our customers. | One-stop service system

Pharmapack can supply the most perfect turnkey packaging solutions for every customer.

|

Industry-leading technology New servo control with self-sensing to replace the old cylinder, dust-free fin, more stable, longer service life, lower maintenance cost. | Excellent quality control Tested by internationally certified companies, Pharmapack equipment has passed CE, UL Certify, CSA evaluation and complies with GAMP, FDA (CFR21), cGMP and TGA standards. |