The editor will introduce two pppharmapack machines to help you understand what continuous inspection machines are. These two pppharmapack machines are LFIM-48 and LFIM-72, respectively.

The LFIM-48 and LFIM-72 continuous inspection machine is tailored for the pharmaceutical industry. It is used for inspection after filling glass bottles of liquid, the purpose is to ensure the safety of oral liquid or injection medication, to prevent the occurrence of drug accidents; It can detect liquid level, defective bottle body and bottle cap, as well as impurities in the bottle like glass fragments, aluminum chips, hair, fiber, precipitates or suspended solids, with high accuracy of detection results and high production efficiency. It is suitable for automatic detection of liquid preparations such as vials, ampoules, eye drops, injections and oral liquid bottles.

Working principle of LFIM-48 and LFIM-72

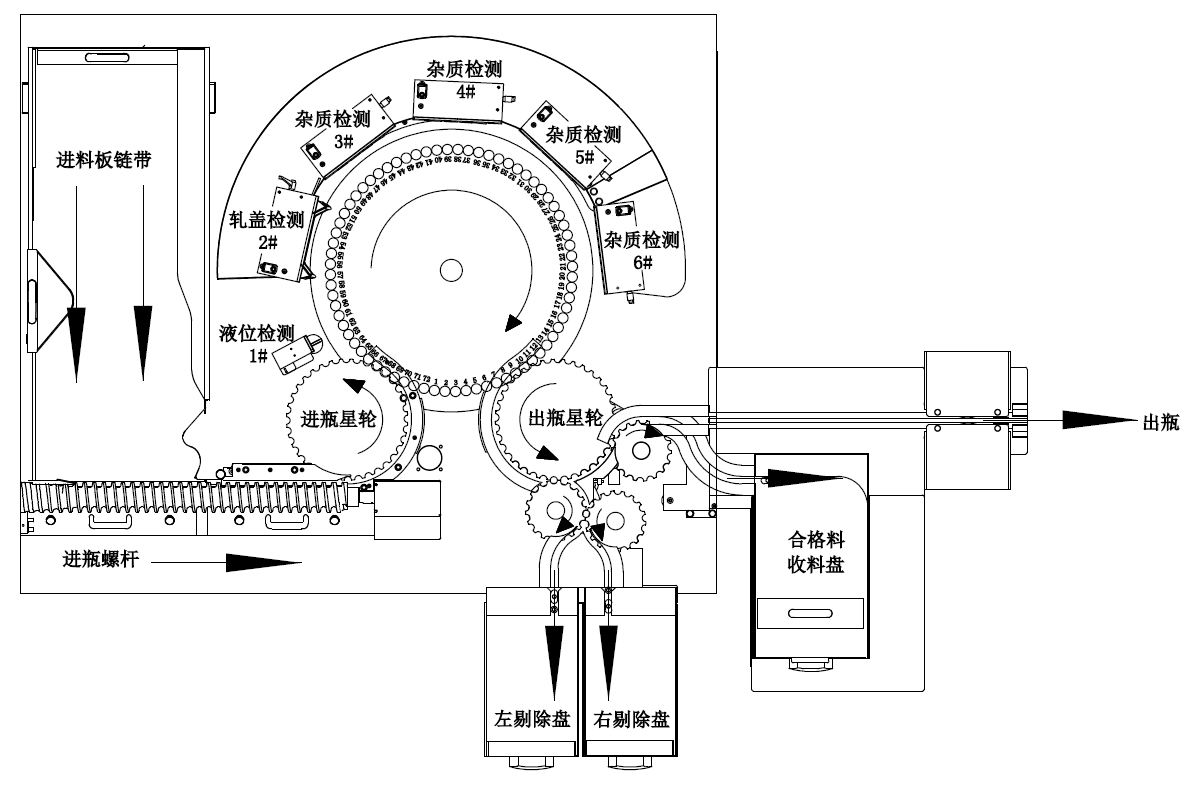

The bottles conveyed from the previous process or manually put the bottles into the vertical loading platform, the conveyor belt of the vertical loading platform conveys the bottles to the bottle feeding screw, the bottle feeding screw conveys the bottles to the bottle feeding star wheel one by one, the unqualified bottles are detected and rejected through the bottle feeding station; the bottles are conveyed to the main tower at an even speed, in the main tower foreign objects, liquid level, cap and bottle foreign objects and cracks are detected through different cameras, the unqualified products The unqualified products are kicked out through the star wheel, and the qualified products are conveyed to the qualified receiving tray or chute; the electric control system provides real-time control feedback through the sensors and cameras of each part to realize the fully automatic operation requirements..

Differences between LFIM-48 and LFIM-72

The two machines are similar in other aspects, the biggest difference is that the maximum production speed of LFIM-72 can reach 800 bottles/minute, while the maximum production speed of LFIM-48 is 400 bottles/minute, so LFIM-72 continuous inspection machine is suitable for the flow line which requires higher speed!

Performance characteristics of LFIM-48 and LFIM-72

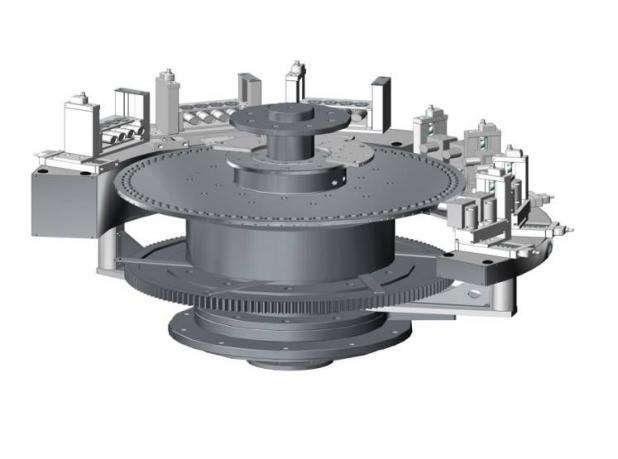

1. Structural innovation

Put the electric control part above, the whole machine integrated design, effectively saving the working space, while avoiding the potential harm to the electric control part due to water cleaning;

The establishment of the bottom inspection station, if the bottle has cracks, it will be automatically rejected before entering the main turret to prevent leakage or bottle breakage after entering the main turret, which is an innovative move to prevent bottle breakage in the turret;

The operating platform is designed in accordance with the sealing process (in line with IP55 requirements), so that in the event of broken bottles during work, it can also ensure that no liquid leakage, to ensure that the parts will not be damaged by liquid leakage, and the operator can safely and quickly clean up the site hygiene; greatly reducing the cleaning time, thereby improving efficiency and product quality; precision spindle suspension structure, to ensure that the machine runs accurately Smooth and stable.

2. Line Integration

The linkage channel is reserved on the discharge port of each machine to connect with the front and rear sections, upstream and downstream equipment, and the whole line is linked with automatic control, which improves the product quality and greatly relieves the increasing labor pressure at the same time. Greatly create value for customers!

Choosing pppharmapack has the following advantages:

1、One-stop service system:

Provide digital management and production solutions for each customer.

2、Superb technical advantages:

With nearly 300 patented technologies and industry-leading servo control technology, we are able to independently develop equipment and manufacturing industry-related software application systems, etc. according to market demand.

3、Digital cloud platform:

Digital cloud platform covering the whole life cycle of the equipment, to achieve digital production, marketing and operation and maintenance.

4、Customized exclusive service:

We provide customized turnkey packaging solutions from the user's point of view. With our profound professional knowledge and rich experience in equipment installation, we can create personalized solutions for our customers based on the data and needs provided by them. Please feel free to contact us.