Efficient packaging helps in cost reduction and productivity enrichment in many industries. Meaningfully, bottle unscramblers are essential; they expeditiously organize and orient bottles for filling and labeling. It boosts throughput and curtails manual labor. Consequently, these machines integrate into production lines while adjusting speed and steadiness. They are adaptable to numerous bottle sizes and shapes. It guarantees resourcefulness across different packaging needs.

(<a href="https://www.freepik.com/free-photo/transparent-plastic-bottles-filled-with-yellow-substance_10228890.htm#query=bottle%20unscramblers%20packaging%20line&position=8&from_view=search&track=ais&uuid=7c9d056b-5a24-4d24-ac1a-3c6c60aa997b">Image by wayhomestudio</a> on Freepik)

A Brief Introduction to Bottle Unscramblers

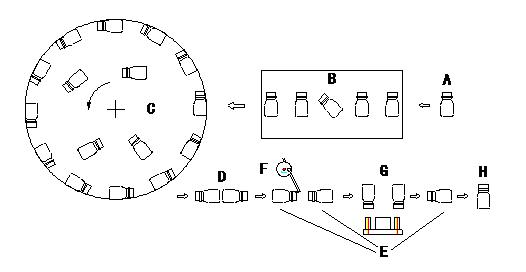

A bottle unscrambler is a high-volume manufacturing machine that organizes and aligns bottles efficiently. Its primary function is to sort a bulk supply of bottles into a single-file line for subsequent processes like filling, capping, or labeling.

This mechanism utilizes a combination of rotating discs, belts, and guides for the unscrambling effect. The relevance of unscrambler machines for bottles is high in industries with strict hygiene and precision requirements, including pharmaceuticals, food, and beverages. Here, the reliability of bottle handling impacts product quality and safety.

In the pharmaceutical industry, for example, an unscrambler machine for bottles confirms that vials or bottles are oriented for precise dosage filling for medication safety. In the food and beverage industry, such a machine facilitates the rapid and hygienic processing of containers, whether glass bottles for sodas or plastic ones for condiments.

Therefore, its efficiency rationalizes the production process and directly assists with preserving the high standards in these sensitive industries. While plummeting manual handling, it underrates contamination risks and augments production speed, which becomes indispensable in contemporary manufacturing lines.

Different Types of Bottle Unscramblers

In this section, let's go through the major types of unscrambler machines for bottles.

1. Rotary Bottle Unscrambler

Rotary ones are celebrated for their high-speed operation in handling many bottle shapes and sizes. Usually, these machines use a rotating disc to orient and feed bottles into a single file for further processing. Ideal for high-volume production environments, including beverage or pharmaceutical industries, rotary unscramblers can process thousands of bottles per hour.

E.g., a rotary unscrambler might be employed in a large-scale water bottling plant where speed and steady bottle orientation are essential. Importantly, they require moderate maintenance due to moving parts, and adjustments might be necessary when switching between different bottle types.

2. Linear Bottle Unscrambler

Linear ones, in contrast, are characterized by their simpler, straight-line operation. They have a more compact design with fewer moving parts, rendering them more accessible to clean and keep. Besides, they are appropriate for lower to medium production rates. Though normally not as fast as rotary unscramblers, they can handle several bottle types.

Linear unscramblers are admirable for smaller operations or facilities that address a broad spectrum of bottle sizes and shapes but do not require the high-speed output of rotary systems. For instance, this type would benefit from a specialty cosmetics company with assorted bottle designs but lower production volumes.

3. Centrifugal Bottle Unscrambler

Last but not least, centrifugal ones use centrifugal force to angle and position bottles onto a conveyor. These machines are acknowledged for their high speed and precision for lightweight and standard-shaped bottles. While they can accomplish high throughput rates, similar to rotary unscramblers, they are less adaptable in handling irregularly shaped bottles.

Centrifugal unscramblers are the epitome of operations where speed and effectiveness with standard bottle types dominate, including in a mass-production soft drink facility. Nevertheless, their complexity may mean higher preliminary costs and maintenance requirements than linear unscramblers.

Recommendation: Pharmapack's LFU-40C High-Speed Bottle Unscrambler

After acquiring the information above, you may have a more comprehensive understanding of the unscrambler machine for bottles. Now, let's look at one of Pharmapack's excellent solutions, the LFU-40C High-Speed Bottle Unscrambler, and some of its features.

l Fully Automatic Intelligent Design:

It supports real-time adjustment of bottle-sorting speed based on the production capacity requirements of subsequent processes, eliminating the need for manual intervention.

l Modular Design:

The bottle-sorting turntable and the main machine are designed as two separate, fully detachable modules. This design ensures seamless integration during usage while allowing convenient separation during idle times, resulting in space-saving efficiency.

l Adaptability to Bottle Specifications:

Our design follows the universal mold application principle for adapting to bottle specifications. Bottles of the same shape are fully interchangeable with different volume specifications, while non-universal cases adhere to a simple and efficient adjustment principle.

l Premium Key Component Integration:

The machine's critical components are carefully selected from internationally renowned and top-quality domestic brands. This approach ensures the machine's reliable functionality, enhances the lifespan of key components, and secures access to premium product services for these critical machine parts.

Suitable for diverse industries, this equipment demonstrates its efficiency with its ability to process up to 400 bottles per minute. It also comes with other exceptional features, like the larger-capacity hopper, bottle inversion & rejection function, and integrated static electricity elimination & dust removal device, making it a progressive packaging system.

Conclusion

Pharmapack, established in 2002, is a packaging machine manufacturer focusing on R&D, manufacturing, sales, and packaging and coding equipment service. Besides our bottle unscrambler solutions, we cover a wide range of products, including tablet & capsule counters, ink-jet printers, labelers, and more.

While certified by internationally recognized companies, our diverse products meet CE, UL, and CSA standards. They comply with GAMP, FDA (CFR21), cGMP, and TGA standards, as well. We take pride in a global marketing and service network, with over 1500 smart bottle packaging lines globally, over 1200 of which are for the pharmaceutical industry.

Visit Pharmapack today! You are guaranteed to find the best-tailored packaging solutions that meet your expectations.