In the pharmaceutical sector, the best pharmaceutical packaging equipment is needed. Because it ensures each package has the correct medication amount, which has a significant influence on health implications. Regarding tablet counting and filling, the tablet counter machine plays its role, and the key is to know which is best for your business operation.

This article will discuss comprehensively all you need to know about the tablet counting machine, covering topics from what tablet counting machines are to how to choose the best automatic counting machine. Read on to have more insights!

What is the Tablet Counter Machine?

The tablet counting machine is a piece of pharmaceutical equipment designed to streamline the tablet counting process. An advanced version can utilize a combination of mechanical, electronic, and optical components to accurately tally the correct number of tablets and fill them into the right container.

In addition to the pharmaceutical industry, these counting machines are indispensable in various industries, including nutraceuticals and food production. They also come in different types, mainly manual counting machines, semi-automatic counting machines, and automatic counting machines, to cater to different needs and scales of operation.

What's the Working Principle of a Tablet Counter Machine?

The three different categories of tablet counting machines have their respective strengths and working principles.

1. How does a Manual Tablet Counter work?

The manual tablet counter is also called the hand-operated tablet counter. They have the simplest counting mechanism and usually consist of dual counting trays made of plastic or metals like stainless steel or aluminum.

Usually, one counting tray comes in a flat plate, while the other counting tray has a certain number of holes that are evenly spaced. The operator needs to place tablets onto the hole-patterned counting tray and gently shake the tray to let the right number of tablets find their holes to fit in. That's how the manual tablet counter counts tablets!

Benefits of Manual Tablet Counters:

l Easy operation, no need for mechanical training

l Lowest costs due to the simplest counting mechanism

l Perfect for small-scale tablet counting

Restrictions of Manual Tablet Counters:

l Least counting speed

l Time-consuming in larger-scale tablet counting

l Possible manual errors due to long-time working

2. How does a Semi-automatic Tablet Counting Machine Work?

The semi-automatic tablet counting machine automates the counting process to a greater extent. Tablets are loaded into the counting machine's hopper and pass through a counting mechanism, where they are counted electronically using sensors or other detection methods.

Once the set count is reached, the machine may automatically release the tablets into the bottle. The human operator's role is to place the bottle under the release point or possibly initiate the release mechanism before bottle filling.

Benefits of Semi-automatic Tablet Counting Machines:

l Improved accuracy and efficiency

l Adaptable for various tablet sizes and shapes

l Cost-effective counting solutions for increased productivity

Restrictions of Semi-automatic Tablet Counting Machines:

l Higher investment compared to manual tablet counters

l Limited speed due to human intervention

l Mechanical training needed for proper operation and maintenance

3. How does an Automatic Tablet Counting Machine Work?

The fully automatic tablet counting equipment represents the pinnacle of efficiency and automation. They can handle a bulk supply of tablets, using advanced counting mechanisms, such as photoelectric sensors or weigh-bridge systems, to count tablets at high speeds.

When the count is reached, the counting machine automatically releases the tablets into the bottle, which is often fed into the machine via a conveyor system. The filled bottles are then automatically conveyed to the next stage of the packaging process.

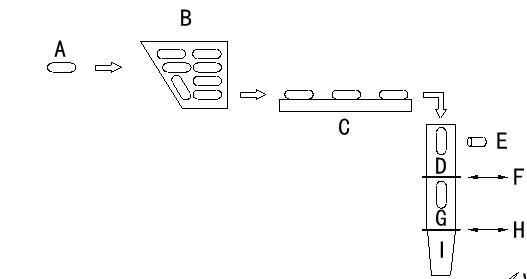

Take Pharmapack's LFM-24 Modular Counter as an example. By integrating it into the present packaging line, the tablets can be loaded into the hopper automatically. Using three-level vibratory plates and optic detection tunnels, they will be sorted in the right amount and then filled in the empty bottle that is transferred by the driving cylinder.

Benefits of Automatic Tablet Counting Machines:

l High-speed counting and filling for bulk packaging

l Advanced mechanism integrated, like built-in software for data management

l Higher versatility for processing tablets in different sizes and shapes

Restrictions of Automatic Tablet Counting Machines:

l High initial costs

l Specialized training needed for effective operation and maintenance

l Space requirements due to the usually larger volume

How to Choose the Right Tablet Counter Machine?

With both benefits and restrictions, different types of tablet counting equipment excel in different applications. To choose the best tablet counting machine, you may consider the following major tips.

Factors to consider when purchasing a tablet counter machine

l Speed and Efficiency Requirements

Evaluate the packaging speed in terms of your production needs. High-volume production may require a fully automatic counting machine. At Pharmapack, you can have automatic tablet counting equipment whose maximum efficiency is 24,000 pics/ min.

l Size and Dimensions of the Tablets Being Counted

Ensure that the counting machine is compatible with the size, shape, and fragility of the tablets being counted to avoid jams, breakage, or inaccuracies.

l Budget and Cost Considerations

Establish a comprehensive budget list that includes the counting machine's price and estimated ongoing expenses such as maintenance, spare parts, and energy consumption. Weigh the initial investment against the potential savings in labor, increased efficiency, and reduced waste.

l Ease of Operation and Maintenance

Opt for a counting machine that is user-friendly and requires minimal training and maintenance to maximize efficiency and minimize downtime. You may consider features like the servo-controlled mechanism, modular designs, and LCD touchscreen.

Features to look for in a tablet counter machine

l Counting Range and Capacity

Choose a tablet counter machine with a counting range and capacity that aligns with your production needs. Consider factors such as batch sizes, production volumes, and fluctuations in demand.

l Accuracy and Precision Levels

Look for tablet counting machines that offer high levels of accuracy and precision to minimize errors, rework, and waste. Consider factors such as counting accuracy, rejection rates, and the consistency of results.

l Integration Capabilities

If you have existing production lines or inventory management systems, ensure that the tablet counting equipment can fit within the available production space and seamlessly integrate with them for streamlined operations.

Conclusion

From manual tablet counters to automatic tablet counting machines, the evolution of counting machines represents significant progress in pharmaceutical and manufacturing processes. Here at Pharmapack, we always stand at the forefront of technological advancements, offering different counting machines for tablets, capsules, and pills.

With 400+ patents in pharmaceutical packaging machine manufacturing, we offer professional one-stop packaging solutions, including automatic stick packing machines, powder filling machines, and sealing detection machines. Our comprehensive service range covers from pre-sale consulting to mechanical training. If you are interested in our services, feel free to contact us for more information.