In the modern production line, the efficiency and stability of every link directly affect the quality and cost of the final product, and automation equipment has become the core force to promote the development of the manufacturing industry. Pharmapack understands the urgent need for increased productivity and cost control. This led to the introduction of the automatic bottling machine series, which embodies Pharmapack's many years of technological accumulation and a deep understanding of market needs, bringing revolutionary changes to the production lines of the pharmaceutical, health products and food industries.

Automatic bottle sorting machine, which can arrange and arrange disorderly bottles through a specific mechanical structure, and then transport them to the next process at a certain speed and sequence. This not only greatly improves the production efficiency, but also reduces the error rate and labor intensity of manual operation.

In the plastic bottle production line, it can quickly and accurately handle various specifications of bottles, ensure the high-speed operation of the production line, and greatly save labor costs to avoid losses caused by human factors.

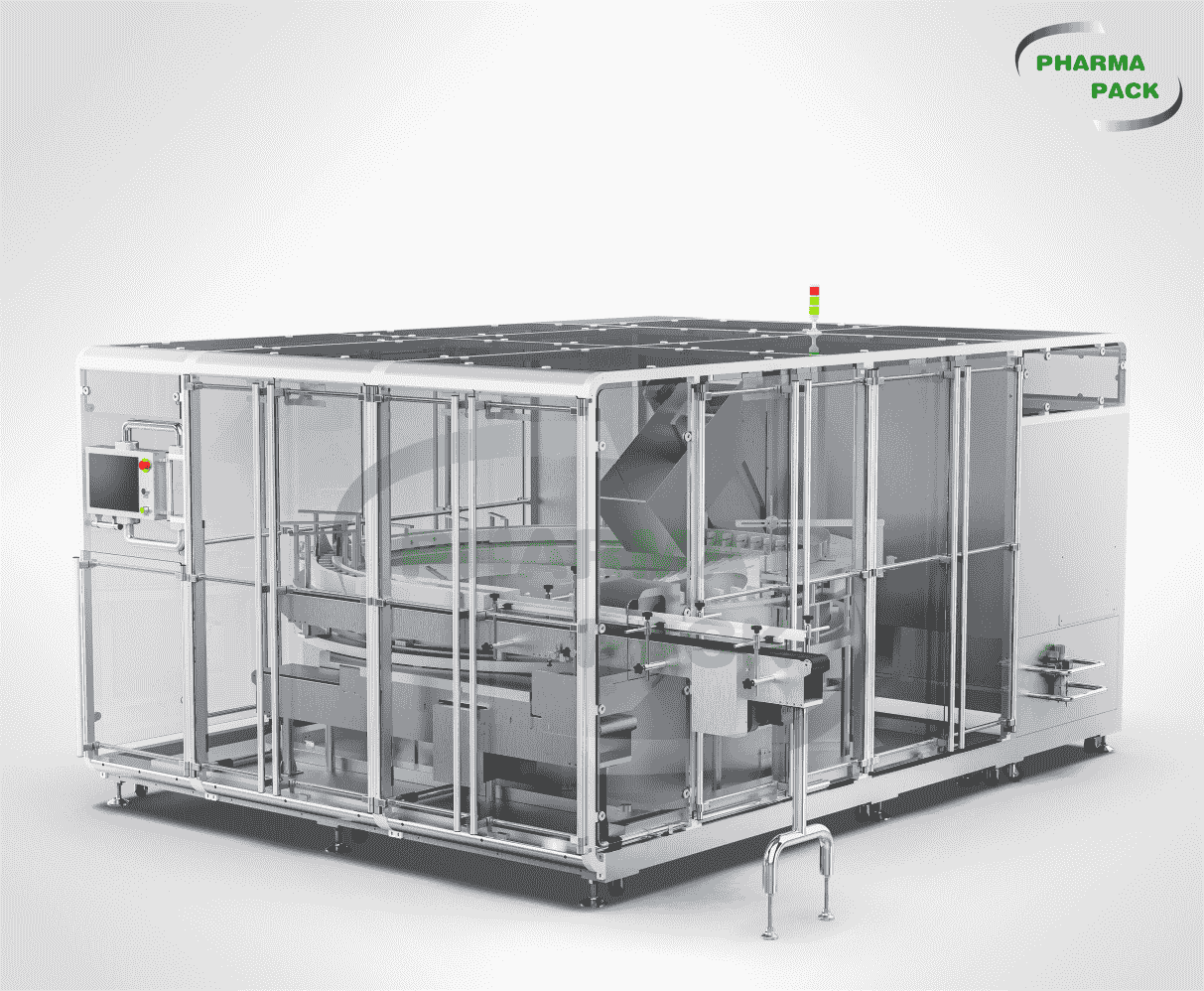

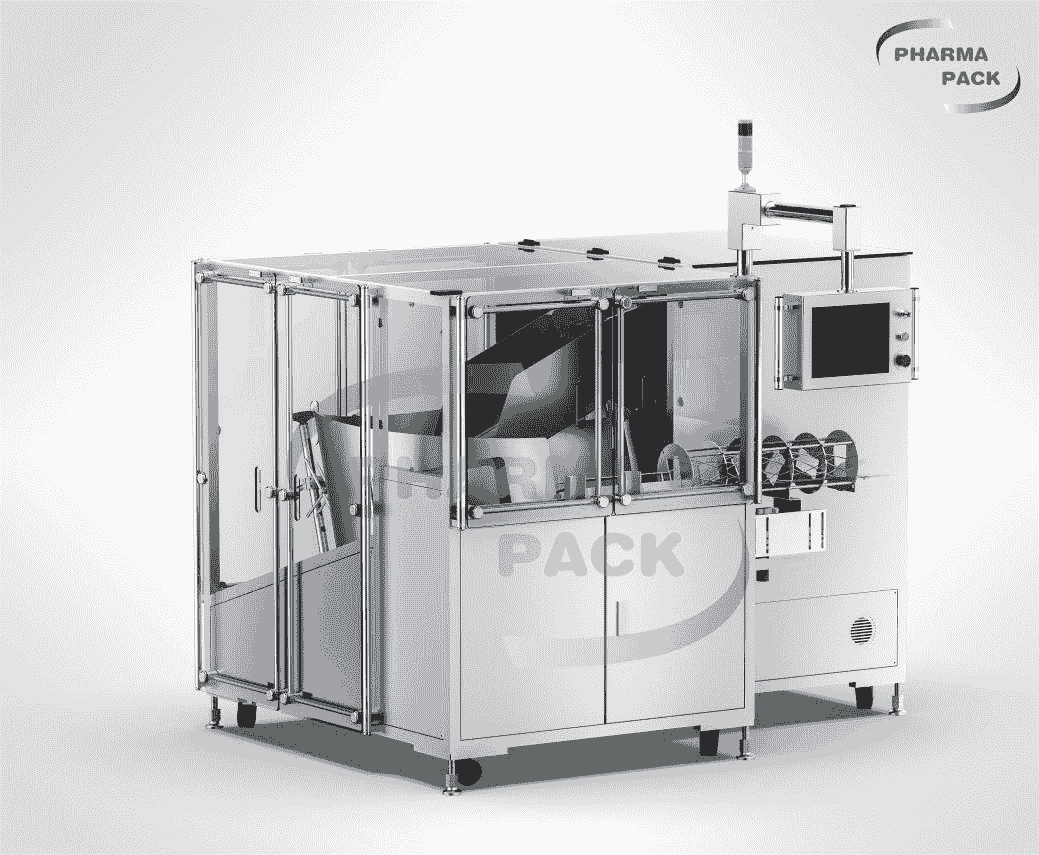

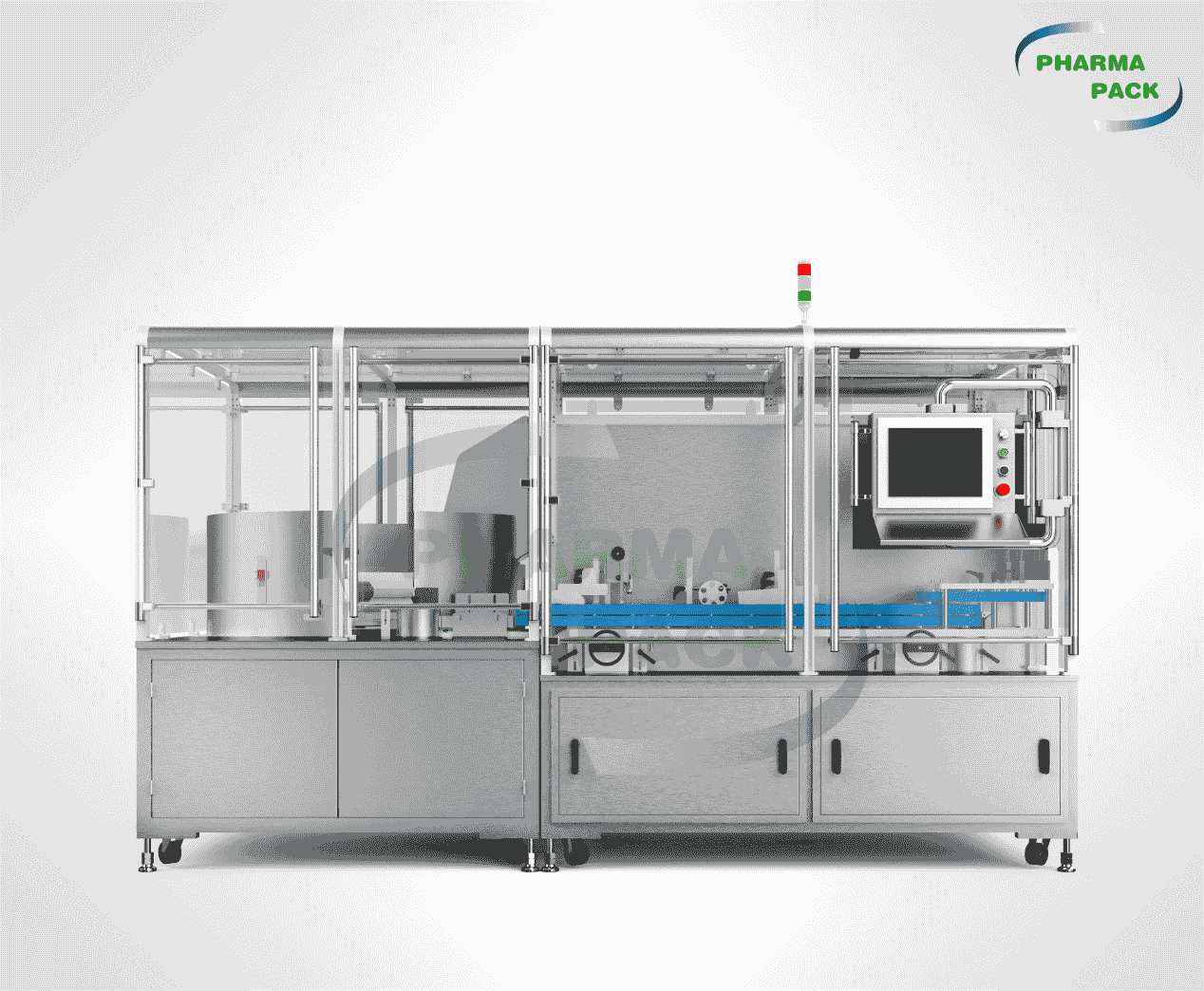

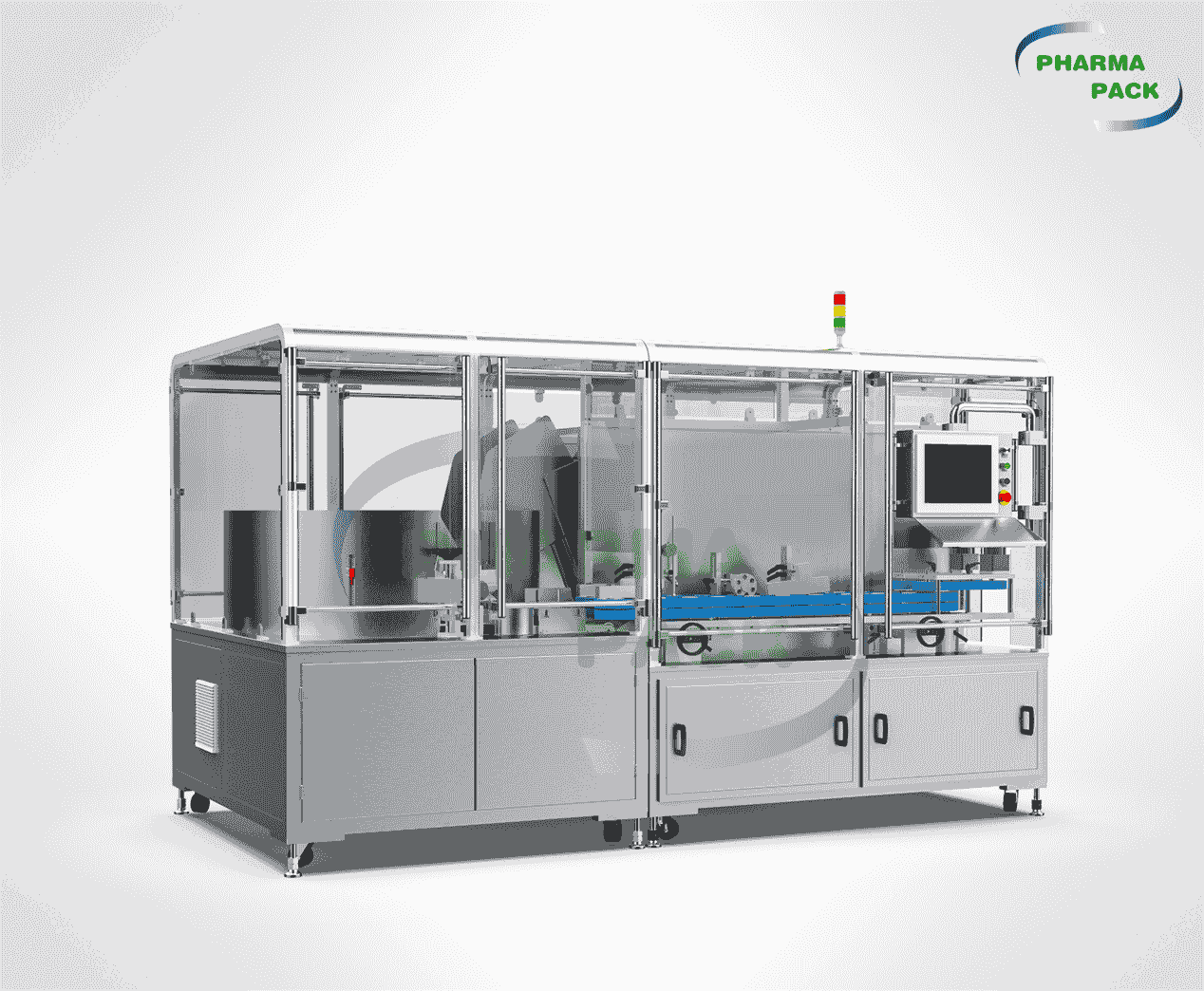

The Pharmapack automatic bottling machine series includes a wide range of models to meet different sizes and needs of production lines.

The following are the main models and characteristics of Pharmapack automatic bottle sorting machine:

1. ALFU-40CAS: Suitable for square bottles and round bottles with a diagonal size of 35-90mm, with a maximum production speed of 400 bottles/min, ideal for high-speed production lines.

2. LFU-15FC: suitable for square bottles and round bottles with diameters of 25-100mm, with a maximum production speed of 150 bottles/min, suitable for small and medium-sized production lines.

3.LFU-25C: Suitable for square bottles and round bottles with a diagonal size of 30-80mm, with a maximum production speed of 250 bottles/min to meet the needs of efficient production.

4. LFU-40CA: Suitable for square bottles and round bottles with a diagonal size of 35-90mm, the maximum production speed can reach 400 bottles/min, which is very suitable for high-speed production lines.

These models not only cover the speed and bottle shape requirements of various production lines, but also ensure the stable transfer and efficient arrangement of bottles during the production process through Pharmapack's careful design.

Choosing the Pharmapack automatic bottling machine means choosing efficient, intelligent and stable productivity. Pharmapack automatic bottle Organizer offers the following advantages:

1. One-click production change, easy operation: equipped with English touch screen, users only need to select the corresponding bottle type program, can achieve one-click production change, no need to replace the mold, greatly saving time and manpower.

2. Electrostatic dust removal, quality assurance: Optional electrostatic dust removal function can effectively remove the static electricity and dust on the surface of the bottle to ensure product quality and avoid pollution problems.

3. Compact structure, beautiful and easy to clean: the use of AISI 304 stainless steel material, compact structure, easy to clean and maintain, in line with GMP standards.

4. Safe and reliable, stable performance: equipped with overload protection function, high safety, the use of high-quality components and parts to ensure stable and reliable operation of the equipment.

5. Perfect after-sales service system: Pharmapack provides professional technical support and maintenance services, so that you have no worries.

In the pursuit of high efficiency and high quality development today, Pharmapack automatic bottling machine with its excellent performance and stable quality, has become the preferred equipment for automated production lines in the pharmaceutical, health products and food industries. By choosing Pharmapack, you are choosing an efficient path to intelligent, automated production.

Pharmapack automatic bottling machine is not only an efficient assistant on the production line, but also a powerful engine for enterprise transformation and upgrading. Contact us now and join hands with Pharmapack to create a new era of smart manufacturing!