In the rapidly expanding pharmaceutical industry, achieving optimal packaging efficiency is crucial for companies aiming to increase productivity, reduce costs and comply with strict regulatory standards. However, the diversity of products and complex packaging requirements poses significant challenges for pharmaceutical companies. To address these challenges, innovative solutions like the Pharmapack cartoner offer a promising way to simplify packaging efficiency and ensure a seamless pharmaceutical supply chain.

In the pharmaceutical industry, packaging efficiency plays a vital role in determining a company's overall success. Efficiency impacts not only productivity and cost-effectiveness but also a company's ability to adhere to strict regulatory guidelines. Well-optimized packaging processes can accelerate medicine delivery to the market, lower operating costs, and enhance product safety and integrity during storage and transportation.

Despite these advantages, there are several factors that affect the packaging efficiency of pharmaceutical companies. For instance, the wide variety of pharmaceutical products creates obstacles to efficient packaging. Tablets, capsules, syringes, liquids, and more require custom boxing methods to fit their specifications while maintaining quality and yield. Additionally, manual packaging processes significantly reduce the throughput of medicine production and increase the risk of human error in assembly and labeling. To achieve increased speed, accuracy, and consistency, versatile and flexible automated cartoners have become a key solution.

Advantages of the Pharmapack Cartoners

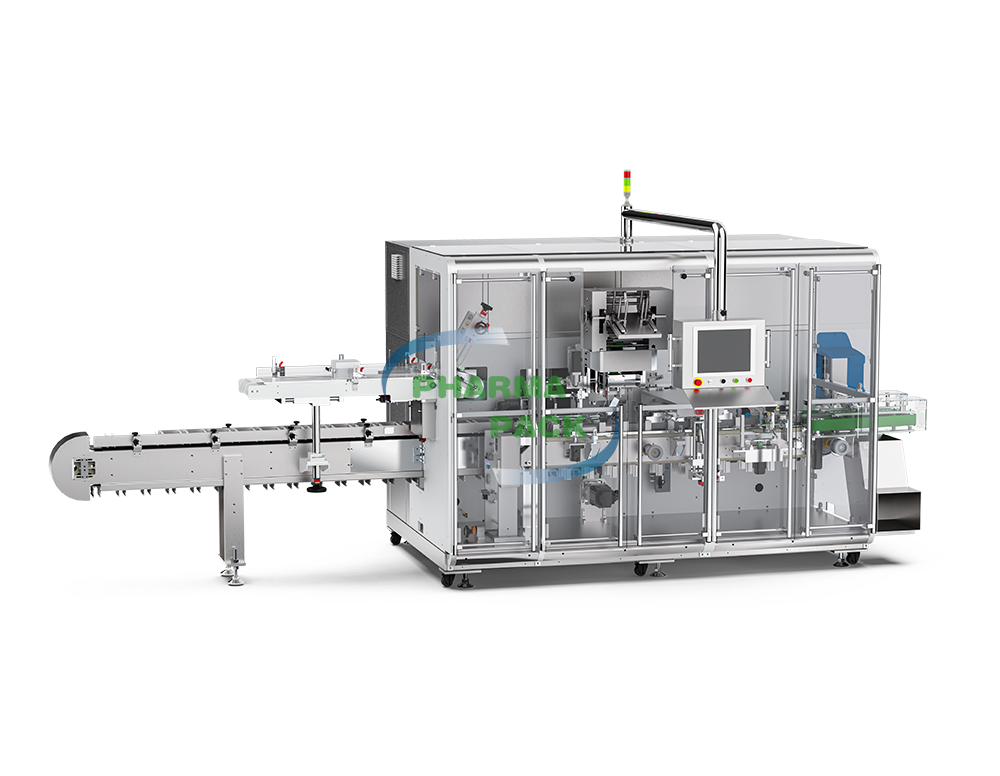

Pharmapack's cartoners provide versatile and high-value pharmaceutical packaging solutions. Their innovative designs enable quick switching between carton sizes and product types, easily catering to various processing needs. These state-of-the-art machines optimize packaging for speed, efficiency, and flexibility.

Pharmapack cartoners excel in maximizing packaging line flexibility and seamlessly accommodating tablets, capsules, liquids, and other products. Their robust construction ensures longevity and reliability, providing a significant return on investment. In addition, Pharmapack's focus on energy efficiency contributes to reduced environmental impact and operating costs.

From intermittent to continuous motion functions, Pharmapack's diverse portfolio of cartoners allows scalability at the right size. Among their standout models are three exemplary choices:

1. ALFBC-40 Continuous Horizontal Cartoner

Designed for large pharmaceutical production lines, the ALFBC-40 Continuous Horizontal Cartoner operates without interruption, packing at an impressive speed of 400 cases per minute. Its separate cabinet design and mechanical pusher ensure hygienic and high-speed packaging while preventing debris from interfering with the drive system. The chain and synchronous belts driving system guarantee synchronized operation across the entire packaging line.

2. ALFBC-25 Continuous Horizontal Cartoner

Offering a multifunctional solution for medium and high-speed packaging lines, the ALFBC-25 Continuous Horizontal Cartoner efficiently packs bottles, blister sheets, racks, and other materials at a rate of 250 cases per minute. It's unique servo motor-based suck and pre-open carton system, along with the double servo motor for insertion, enables easy vertical and horizontal adjustments. Furthermore, the Infeed conveyor, carton infeed belt, carton base conveying, and all the carton tuck-in are suspended. The compact design not only optimizes space utilization but also makes it easier to clean and maintain.

3. LFBI-10 Intermittent Horizontal Cartoner

The LFBI-10 Intermittent Horizontal Cartoner only takes up small space and is designed for small operations. With the main and auxiliary driving parts conveniently installed on the side of the conveying mechanism, daily cleaning and maintenance become hassle-free. The scratch-resistant white-toothed conveyor chain of LFBI-10 can ensure that the carton will not be scratched during transportation and maintain the integrity of the box. Moreover, the design of this product complies with GMP standards and relevant safety regulations, ensuring compliance with industry standards for electrical circuitry, noise level, and safety protection.

In the highly regulated pharmaceutical industry, optimizing packaging is critical to business success. Manual packaging not only slows down the production but also increases the risk of errors. Pharmapack's innovative cartoners offer automated and adaptable solutions to address these challenges effectively.

Discover how Pharmapack can simplify your pharmaceutical packaging, get in touch with our team today! Our experts can identify the ideal cartoner for your product variety, volume, and business goals. For pharmaceutical companies looking to enhance their packaging capabilities, Pharmapack's cartoners are a reliable and innovative choice.

Contact us if you are interested in Pharmapack's products!

Related Articles:

Efficiency and Precision Combined:The Game-Changing Pharmapack Labeler

Maximizing Productivity with Pharmapack’s 360-degree AI Counting and Sorting Machine

Interpack 2023: Pharmapack Showcase Advanced Packaging Solution