Product packaging plays a vital role in ensuring merchandise quality and appearance, but it can also be a complex and time-consuming process. In today’s competitive marketplace, efficiency and precision are crucial determinants of a company’s success or failure. Pharmapack, a leading supplier of innovative packaging solutions, understands the challenges faced by businesses and has developed a range of labelers that have revolutionized the packaging industry. In this article, we explore the features and benefits of Pharmapack’s labeler and their impact on packaging efficiency and precision.

Overview of Pharmapack’s Labeler

Pharmapack’s labeler is an advanced machine engineered to streamline the labeling process and enhance overall packaging efficiency. It processes a variety of features and capabilities that distinguish it from traditional labeling methods. This cutting-edge labeling solution caters to various packaging requirements, offering versatility and adaptability across different industries. Key features of this labeler include high-speed operation, intelligent automation, and advanced technology for precise and consistent application without manual intervention. It can handle various labeling tasks, including applying labels to different surfaces and containers, making it a revolutionary tool in packaging.

The operation principle of Pharmapack’s labeler is based on automation and innovation. By using cutting-edge technology, the machine can automatically apply labels to a variety of products, eliminating the need for labor-intensive manual tasks. Its precise mechanism ensures accurate label placement, regardless of the product’s shape, size, or packaging material. This automation reduces human error, increases productivity, and delivers consistent labeling results.

The applications of Pharmapack’s labeler are diverse and meet the needs of countless packaging scenarios. Whether it’s round bottles, top and bottom labeling, or vertical square and round bottles, Pharmapack’s labeler solutions provide efficient and precise labeling for a wide variety of products. This flexibility allows various industries, including pharmaceuticals, food and beverages, cosmetics, and more, to benefit from its capabilities.

Pharmapack’s Labeler Solutions

Pharmapack offers a range of labeler solutions to meet specific packaging requirements. Let’s explore three of their innovative labelers in more detail:

LFLBR-124032 Rotary round bottle labeler

The LFLBR-124032 rotary round bottle labeler is specifically designed for round bottles. It utilizes a rotating mechanism to seamlessly and accurately apply labels to the curved surface of the bottle. Adjustable settings and high-speed operation ensure efficient labeling, even in high-volume production lines. The machine features a German SEW variable frequency stepless speed motor, a power overload protection device, and is equipped with double ultraviolet detection, enabling the automatic elimination of missing labels. Moreover, the machine’s frame is constructed with stainless steel AISI304, complying with GMP requirements. Its efficient functions make it an ideal choice for companies in need of versatile and precise round bottle labeling, assisting in the efficient labeling of pharmaceuticals, beverages, and other industries.

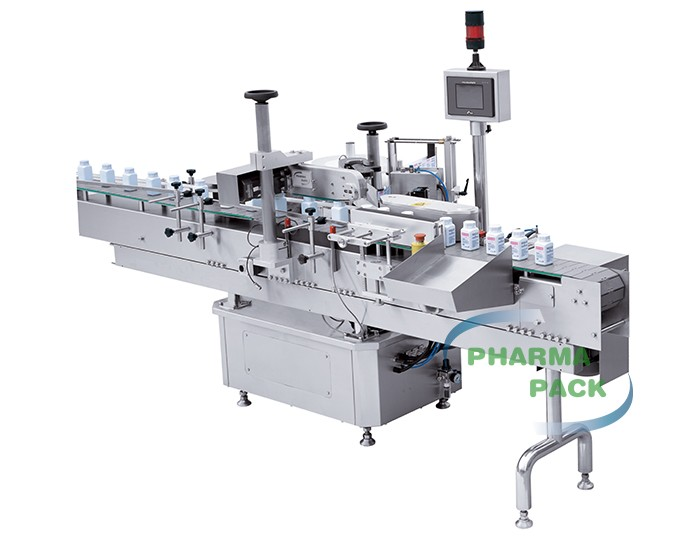

LFLB-4220 Top side & bottom side labeling machine

The LFLB-4220 top side & bottom side labeling machine can simultaneously apply labels to both the top and bottom of a product. This ensures complete and professional-looking packaging, especially for boxes or containers requiring labeling on multiple sides. Its high-speed operation and precise label placement optimize efficiency while maintaining consistent label quality. Its dual labeling capability caters to various industries, including electronics, cosmetics, and consumer goods.

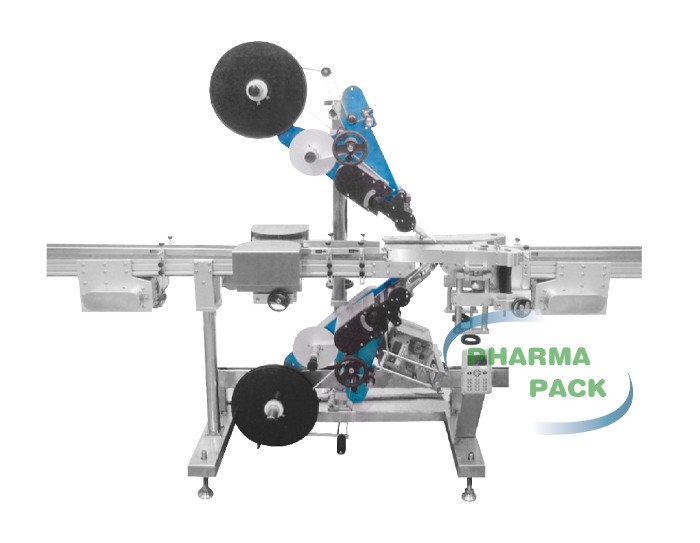

ULFLB-1120-03 Vertical square round bottle labeling machine

The ULFLB-1120-03lvertical square round bottle labeling machine is an ideal choice for the flexibility and accuracy in vertical labeling of square or round bottles. It can handle various sizes and shapes of bottles, making it suitable for a diverse product line. Its advanced sensor technology and adjustable labeling parameters guarantee precise labeling positions, improving packaging precision and aesthetics. Its adaptability allows seamless labeling in chemicals, nutraceuticals, and more industries.

The Impact of Pharmapack’s Labeler on Efficiency and Precision

Pharmapack’s labeler has significantly changed the packaging process, greatly impacting efficiency and precision.

Firstly, automation and advanced labeling technologies have revolutionized production speed. The labeler’s high-speed operation ensures fast and continuous labeling, significantly reducing packaging times. By cutting down on manual labor and accelerating production lines, Pharmapack's labeler enhances efficiency. This increased efficiency translates into higher productivity, allowing businesses to meet growing demand and maintain competition in the market.

Secondly, Pharmapack’s labeler minimizes labeling errors and improves accuracy. With intelligent automation and precise mechanisms, the machine consistently applies labels in the correct position and orientation. This eliminates common mistakes that occur during manual labeling, such as misalignment or uneven application. By reducing the risk of mislabeling or improper packaging, the labeler helps produce a higher-quality final product.

Ultimately, Pharmapack’s labeler had a positive impact on labor efficiency and cost savings. By automating the labeling process, companies can reduce their reliance on manual labor and reallocate resources to other critical tasks. This optimizes labor utilization and decreases labor costs. Furthermore, the accuracy and consistency of the labeler minimize material waste, further contributing to cost savings.

Efficiency and precision are essential factors in the packaging industry, and Pharmapack’s labeler excels in both. It allows enterprises to revolutionize their packaging processes, ensuring efficiency and precision that meet the demands of the modern market. Explore the range of Pharmapack labeling solutions, unlock new possibilities for your packaging needs, and experience the game-changing impact of this remarkable technology. Contact us for more information!

Related articles:

Maximizing Productivity with Pharmapack’s 360-degree AI Counting and Sorting Machine

Interpack 2023: Pharmapack Showcase Advanced Packaging Solution

A Complete Guide to Pharmapack 3-in-1 Single-Row Automatic Packing Machine