Quality is one of the paramount requirements for each and every industry in the world today, ranging from pharmaceuticals to basic manufacturing. This is especially true in the pharmaceutical sector, where the margin for error is virtually non-existent. Quality assurance in the pharmaceutical industry not only safeguards public health but also reinforces the trust and credibility of pharmaceutical manufacturers. Recognizing this evolving need, we have positioned ourselves at the forefront of innovation, particularly with our Continuous Inspection Machine,

Understanding the importance of quality control in the pharmaceutical industry, we have developed different Continuous Inspection Machines, a testament to the company's dedication to pushing the boundaries of what's possible in quality assurance. These products represent a significant leap forward in ensuring the integrity and safety of pharmaceutical products, thereby upholding the industry's stringent quality standards.

Essentials of Continuous Inspection

As the name suggests, continuous inspection is an uninterrupted, real-time process of evaluating products during manufacturing. It is an important means of early defect identification and rectification within the production cycle, which assures that the product is saved from wastage and any potential risk to consumer safety is averted.

This means that continuous inspection maintains standards and improves the quality and reliability of each product running in the manufacturing line.

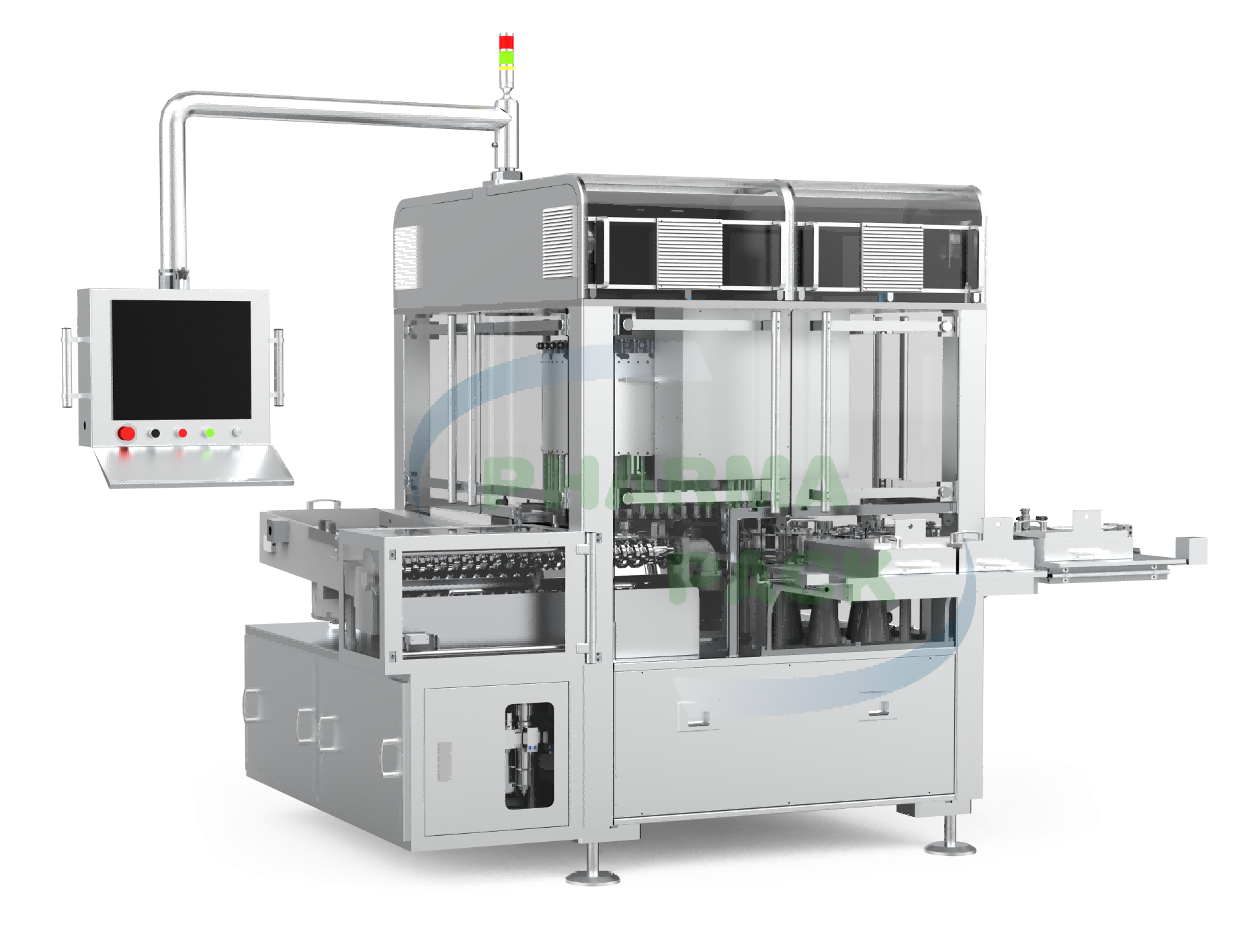

The most modern technological advances in this respect are those credited to the LFIM-48 and LFIM-72 models under Pharmapack's Continuous Inspection Machines. All are designed to ensure quality assurance. The developed machines are capable of identifying even the smallest and almost invisible inconsistencies or imperfections in medicines.

This will help, to a greater extent, pharmaceutical manufacturers to improve the quality control in the products they manufacture so that all of them comply with the highest standards of required safety and effectiveness.

Key Features of Pharmapack's Inspection Machines

The LFIM-48 and LFIM-72 boast impressive operational capabilities, including high speed and unparalleled accuracy in detecting inconsistencies. These machines are adept at identifying a wide range of defects, from physical deformities to chemical discrepancies, ensuring comprehensive quality assurance across all stages of production.

Furthermore, the flexibility and user-friendly aspects of such machines will highlight the ease of integrating and operating the equipment in the already existing pharmaceutical manufacturing systems. This integration ensures that implementing state-of-the-art inspection technology does not have to come at the cost of operational disruption or steep learning curves.

Technical Advantages for Various Industries

Whereas the gains for the pharmaceutical industry from adopting Continuous Inspection Machines are huge, the consequences will reverberate far and wide. Industries such as food and beverage, cosmetics, and any other sector requiring stringent quality control can leverage the technical prowess of the LFIM-48 and LFIM-72 to enhance product reliability. The adoption of such advanced inspection technology also ensures compliance with global quality standards, significantly reducing the risk of recalls and waste.

In an era where quality assurance cannot be compromised, Our Continuous Inspection Machines emerge as essential components of a robust quality assurance strategy. They do much more than simply help maintain standards: the LFIM-48 and LFIM-72 represent investments in operational efficiency, product integrity, and, finally, consumer trust.

In turn, new technologies develop from newly created methods and materials, and these arise just as a consequence of continuous development and investments into research on product safety and quality parameters. Due to the changes experienced in pharmaceuticals and other areas, there is a need for reliable, efficient, and continuous inspection processes.

Embracing Pharmapack's Continuous Inspection Machines is more than a step towards enhanced quality control; it's a leap towards securing a future where excellence is not just pursued but achieved.

For more information, feel free to contact us!

More articles:

Unveiling Precision: The Automatic Leak Detection Machine LFIV-25

Pharmapack's New Product Lineup: Redefining Pharmaceutical Quality Control

An Inside Look at Pharmapack's Cutting-Edge Inspection Technology in the ALFIM-72