In the rapidly evolving realm of pharmaceuticals, maintaining unwavering quality control remains crucial. Enter Pharmapack's introduction of the AI Continuous Inspection Machine with Leakage Detection ALFIM-72 represents an advancement in precision and reliability in the pharmaceutical industry.

AI Continuous Inspection Machine with Leakage Detection ALFIM-72 embodies technological ingenuity, integrating advanced artificial intelligence with high-voltage leak detection mechanisms. This equipment meticulously scrutinizes an array of liquid formulations, including vials, ampoules, eye drops, injectables, and oral liquid bottles. Its primary goal is to guarantee impeccable integrity and adherence to the industry's most stringent quality benchmarks.

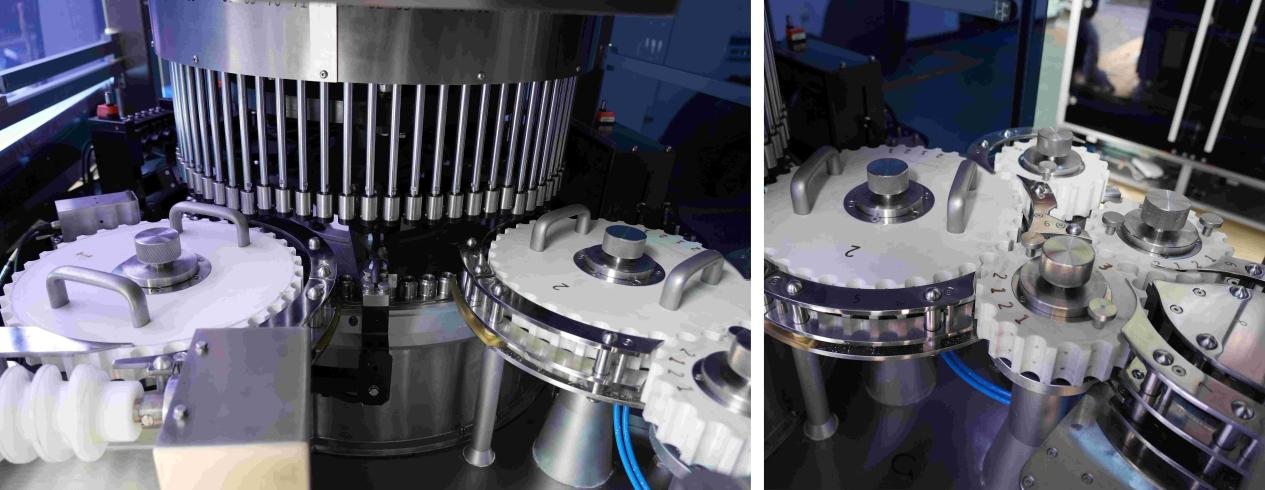

Component Assembly and Precision

At the core of ALFIM-72's sophistication lies an assembly of components: 72 bases, each housing 18 servo motors meticulously crafted by APM in the USA and supported by high-precision 6-grade gear transmission, bearings sourced from industry leaders SKF in Sweden and NSK in Japan, pneumatic elements from FESTO in Germany, and SMC in Japan, alongside Huichuan servo motors and controllers. This ensures stability and the precision required for accurate detection and rejection of faulty products.

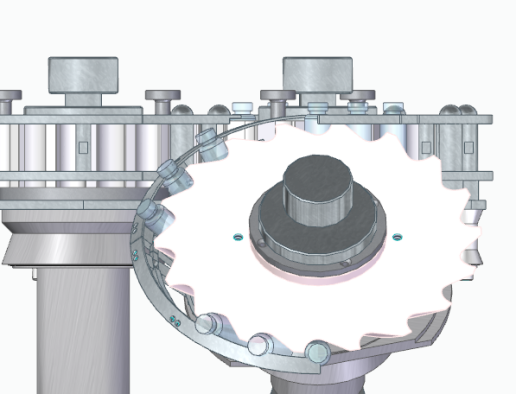

Operational Process and Inspection Methodology

The operational process of ALFIM-72 epitomizes technological finesse in action. Bottles designated for inspection are conveyed onto a vertical feeding platform or manually placed. Subsequently, the conveyor belt on this platform ushers the bottles to the feeding screw, orchestrating their sequential transfer to the inlet star wheel. Within the central tower, cameras meticulously inspect foreign objects, liquid levels, bottle caps, body irregularities, and potential cracks.

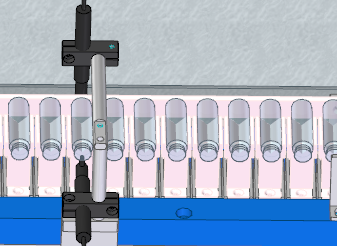

High-Voltage Discharge Leak Detection Mechanism

The hallmark of ALFIM-72's competence is its high-voltage discharge leak detection mechanism, discerning leaks exceeding 1μm. This robust mechanism ensures the expulsion of compromised products while safeguarding the passage of approved items for further processing or manual collection. Its electronic control system orchestrates real-time control feedback, ensuring adherence to the strict requirements of complete automation.

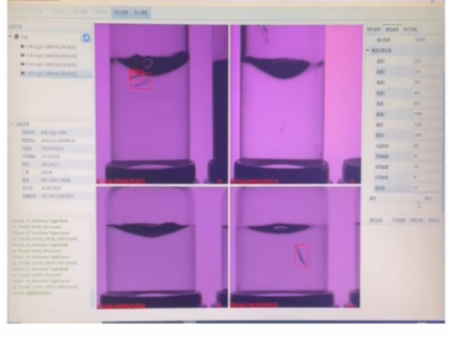

AI-Driven Visual Detection System

Central to ALFIM-72's prowess is its advanced AI visual detection system. By leveraging deep learning and machine vision, this system is designed to minutely examine pharmaceutical liquid formulations and meticulously identify the slightest impurities, irregularities, and foreign particles. This guarantees that the packaged products conform to the most stringent safety and quality standards.

Compliance and Importance in Pharmaceutical Testing

Pharmaceutical products require particularly sensitive testing due to stringent regulations and safety concerns. ALFIM-72 guarantees the safety and reliability of critical pharmaceutical products such as penicillin vials, ampoules, eye drops, injectables, and oral liquid bottles, ensuring they meet stringent standards for pharma packaging. Its AI-driven vision inspection ensures that pharmaceutical packaging equipment undergoes rigorous quality checks aligned with the sector's uncompromising standards.

Within ALFIM-72, a network of six sets of inspection stations and 21 cameras ensures comprehensive scrutiny. With one camera dedicated to liquid level detection, another for cap detection (comprising four cameras), and four groups (16 cameras) devoted to impurity glass and bottle body detection, the system operates at a resolution of 2-megapixels. This remarkable capacity enables it to flag even the most infinitesimal impurities, cracks, or potential leaks that might undermine the efficacy and integrity of liquid formulations.

ALFIM-72's unparalleled defect detection capabilities ensure the delivery of impeccable pharmaceutical products to end consumers, safeguarding their safety and well-being.

Structurally, ALFIM-72 is designed for efficiency and user-friendliness. Its compact design optimizes the workspace while ensuring high performance, catering to the stringent demands of pharmaceutical quality control and enhancing the functionality of pharma packaging equipment. Moreover, it complies with industry regulations, setting new standards for pharmaceutical quality control systems.

As a leading solution in the pharmaceutical quality assurance landscape, ALFIM-72 redefines precision, reliability, and safety. To optimize your pharmaceutical production and guarantee the utmost in product quality, consider integrating ALFIM-72 into your operations. Contact us today to learn more about how ALFIM-72 can enhance your quality control processes and elevate your commitment to excellence.

Related Articles:

Pharmapack's New Product Lineup: Redefining Pharmaceutical Quality Control

The Precision and Efficiency of Pharmapack's Powder Filling Machine

Efficiency and Precision Combined:The Game-Changing Pharmapack Labeler