The Overall Guide

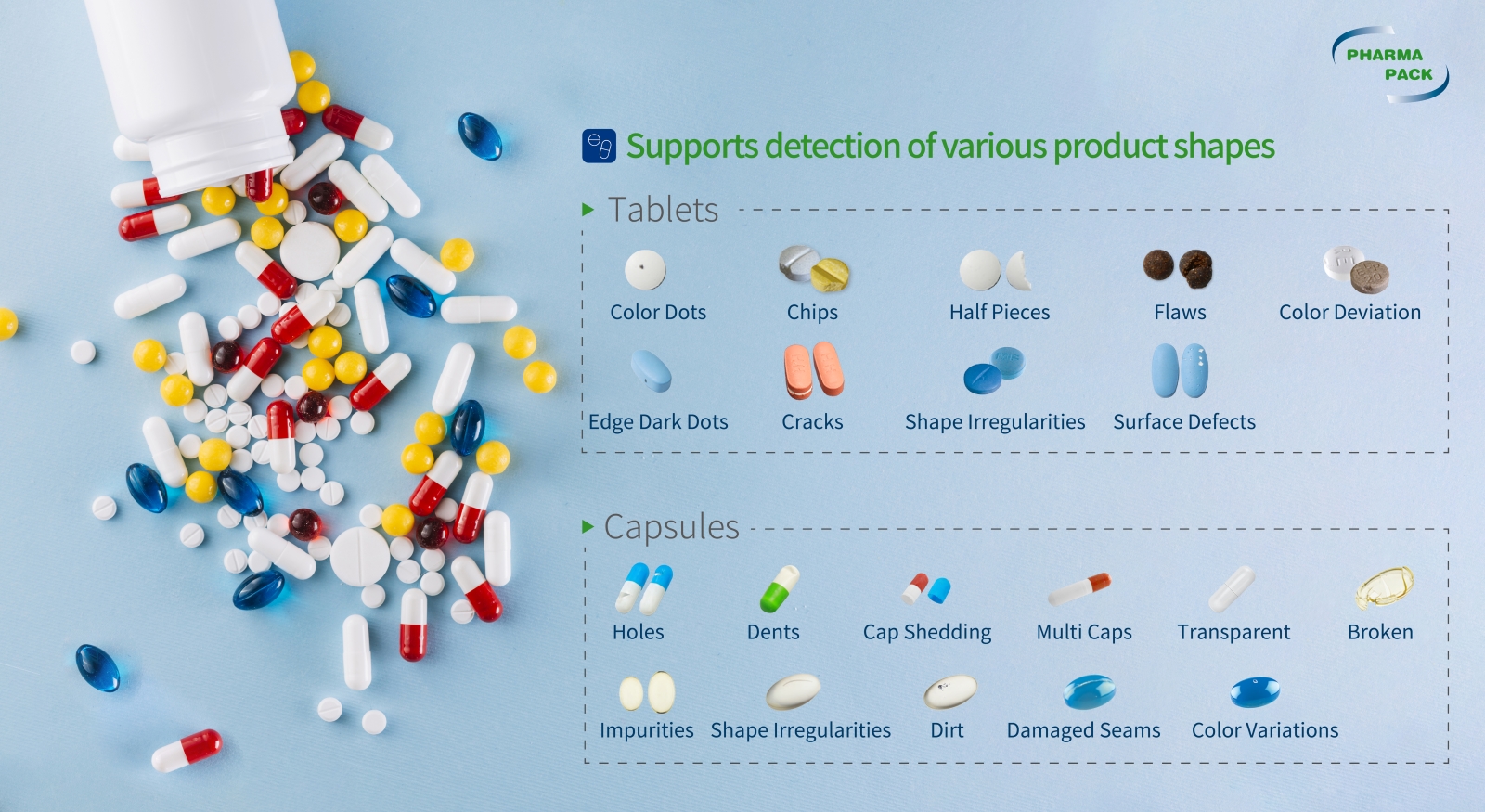

Pharmapack Visual Inspection Machines

The automated inspection system is important in your pharmaceutical packaging line. Visit Pharmapack to see what Pharmapack offers for you, and read on to see Pharmapack's solutions regarding visual inspection equipment!

Visit Pharmapack

Why is Pharmaceutical Inspection Important?

Pharmaceutical inspection is important, as all pharmaceuticals are closely relevant to public health. It ensures the quality and efficacy of pharmaceutical products, enhancing drug safety.

Visual inspection machines play a significant role in this. They ensure pharmaceutical companies adhere to strict regulations set by agencies like the FDA, EMA, and others. High-quality inspections foster trust among healthcare providers and consumers, which is essential for the success of a pharmaceutical company.

Strengths of Pharmapack's Automated Visual Inspection Machines

High Accuracy

Pharmapack's vision inspection machines utilize leading imaging technology, including high-resolution cameras and advanced image processing algorithms. They ensure that even the smallest defects are detected with precision.

High Speed

These automated inspection systems can run at a high speed, ranging from 400 to 800 vials per minute. With a professional R&D team, Pharmapack's vision inspection machines have advanced features, like the high-speed DSP image processing system.

Compact Design

The compact design of Pharmapack's visual inspection machines makes them fit into various production environments. The modular design integrated different parts seamlessly, greatly minimizing space and maintenance needs.

Pharmapack's Visual Inspection Machines

LFIM-48 Continuous Inspection Machine

This automated visual inspection machine can handle bottles that are 20-36 mm in diameter and 40-120 mm in height. The maximum processing speed is 400 vials per minute, and the types of defects or issues that it can detect include foreign matter, impurities, liquid level, and bottle integrity (including the body and the cap).

Find Out More

LFIM-72 Continuous Inspection Machine

This inspection machine can operate at a maximum speed of 800 vials per minute. It handles bottles with diameters ranging from 10 to 25 mm and heights ranging from 20 to 150 mm. The high-solution camera detection can check the bottle's integrity and whether the liquid is pure or not and is on the right level.

Find Out More

LFIM – 60/84 Continuous Inspection Machine

The LFIM-60 can function at a maximum speed of 450 bottles per minute and handle vials that are 10-30mm in diameter and 20-150mm in height. Meanwhile, the LFIM-84 can run at a maximum speed of 800 bottles per minute and handle vials that are 10-22mm in diameter and 20-150mm in height. They utilize high-speed cameras with 300 frames per second. Each of them features an innovative DSP image processing system by using leading parallel processing technology. They examine the whole structure of the vials, checking for any defects in the cap, body, and base.

Find Out More

Who is Pharmapack?

Established in 2002, Pharmapack is a global packaging machine manufacturer offering multiple automatic packaging solutions. We have R&D and engineering centers in Italy and China, developing leading packaging machines, including automatic stick packing machines, case packers, and inspection machines. Pharmapack's expertise is trusted by brands in the pharmaceutical, personal care, and food industries. Some of them are Baxter, Johnson, P&G, L'Oreal, MARS, and Nestle.

20+

Years of Experience

50+

Satisfied Clients

1500+

Production Lines Applied

400+

Innovate Patents

Pharmapack's Other Popular Solutions

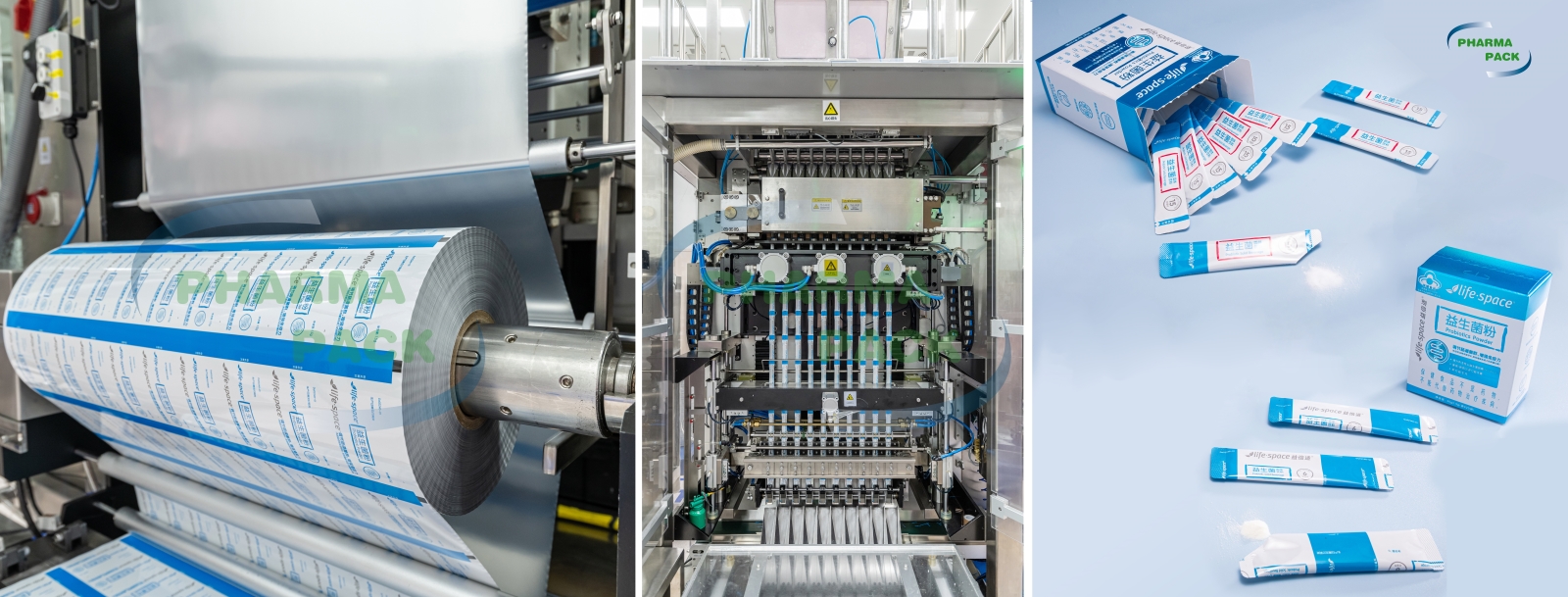

Pharmapack Stick Pack Machine Solutions

Pharmapack's stick pack machines come in different models. They are widely applied in industries such as pharmaceuticals, cosmetics, and food.

Read More

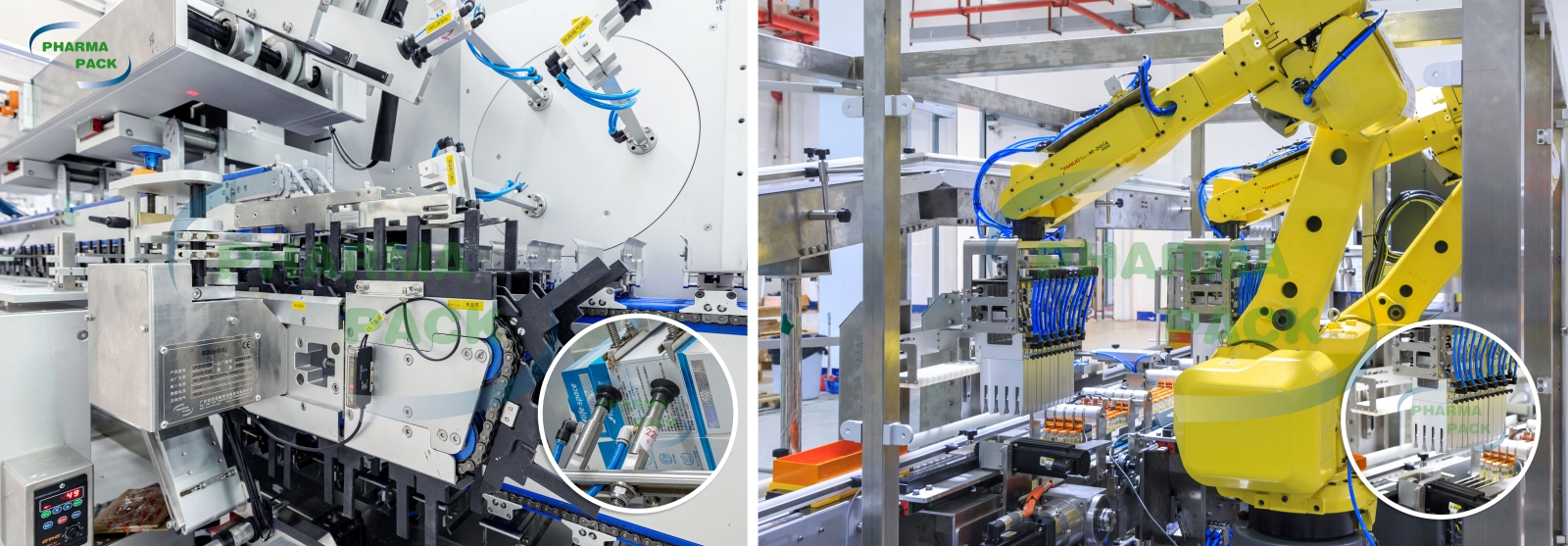

Pharmapack Case Packer Machine Solutions

Pharmapack's case packer machines are high-speed and reliable. There are horizontal, vertical, and automatic case packers for your choice.

Read More

Pharmapack Filling Equipment

Pharmapack has diverse filling and counting machines. There is equipment for filling or counting powder, soft gels, capsules, and more.

Read More

Pharmapack Cartoning Machine Solutions

There are many cartoning machines at Pharmapack, including intermittent-motion cartoners and continuous-motion cartoners.

Read More

Pharmapack Bottle Labeling Machines

At Pharmapack, there are side labeling machines, horizontal labeling machines, vertical labeling machines, rotary labeling machines, and more!

Read More